Manufacturing

Effective filtration of industrial manufacturing fluids is critical to facility operations and product quality. OEI designs magnetic filtration solutions optimized for CNC machining, parts washing, hydraulics, process water systems and engines.

Feature Case Study

ROI: Eliminated Valve Failures

Annual Cost Savings of $25,200

Company

Ingersoll

Location

Calgary, Ab Canada / 2013

Equipment:

Rand High Pressure Air Compressor

Application:

Lube Oil

Challenge:

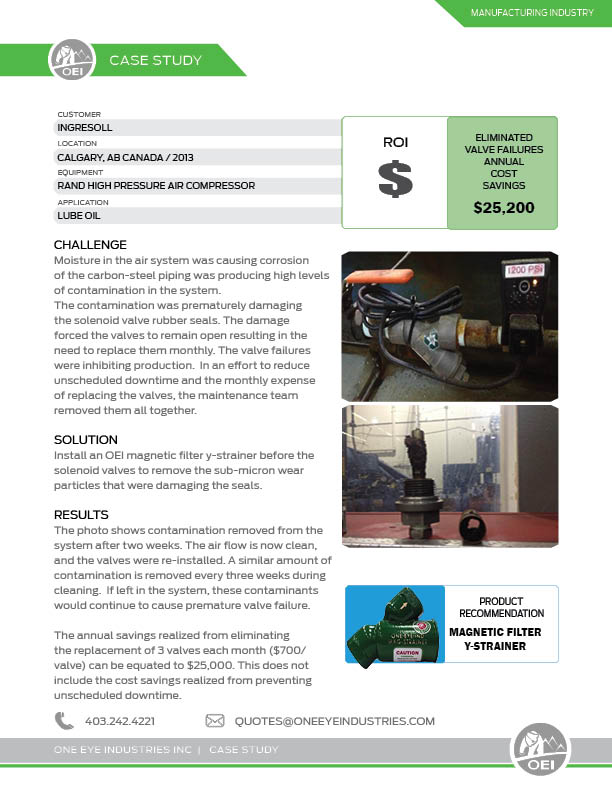

Moisture in the air system was causing corrosion

of the carbon-steel piping was producing high levels of contamination in the system.

The contamination was prematurely damaging the solenoid valve rubber seals. The damage forced the valves to remain open resulting in the need to replace them monthly. The valve failures were inhibiting production. In an effort to reduce unscheduled downtime and the monthly expense of replacing the valves, the maintenance team removed them all together.

Solution:

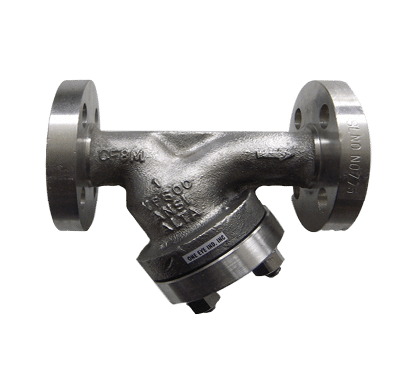

Install an OEI magnetic filter Y-Strainer before the solenoid valves to remove the sub-micron wear particles that were damaging the seals.

Result:

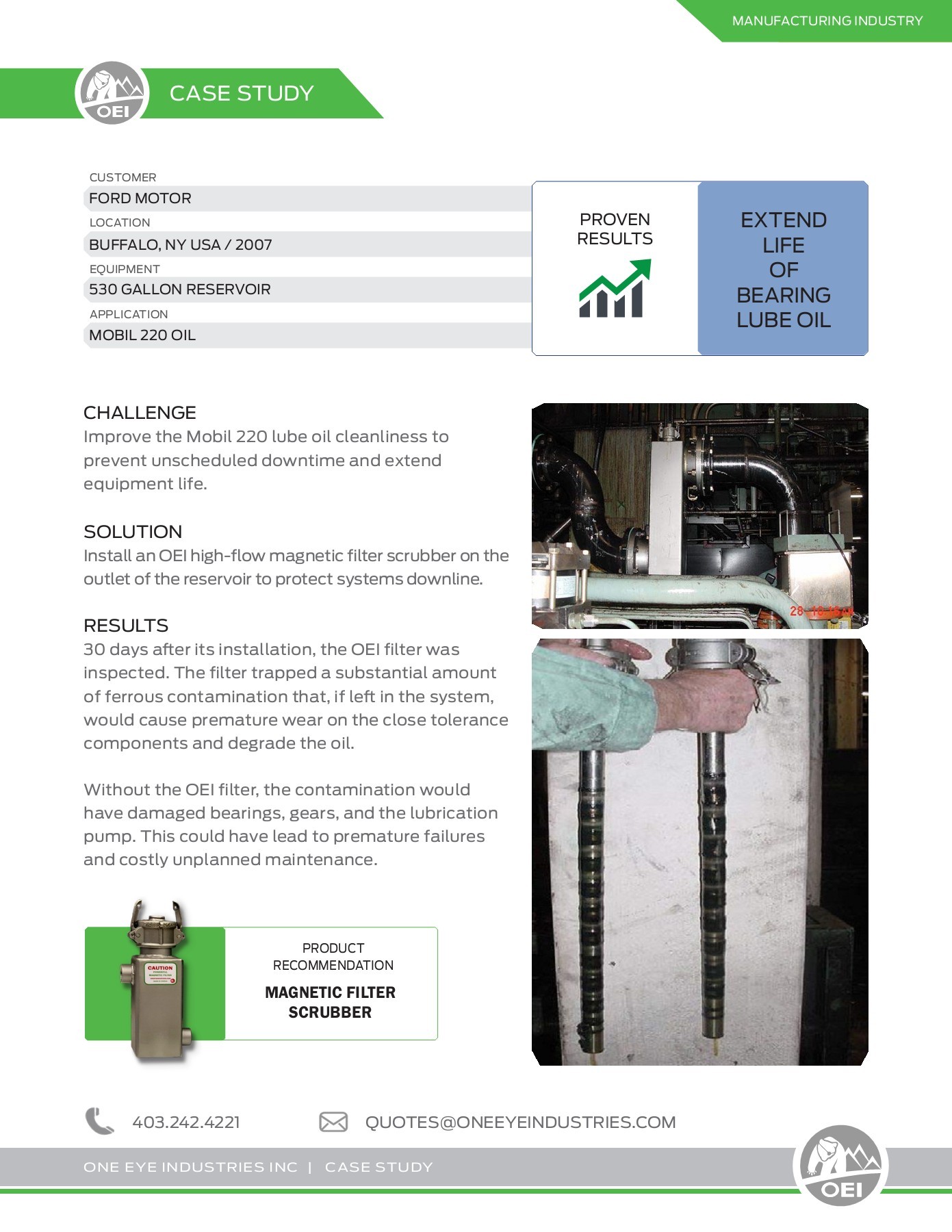

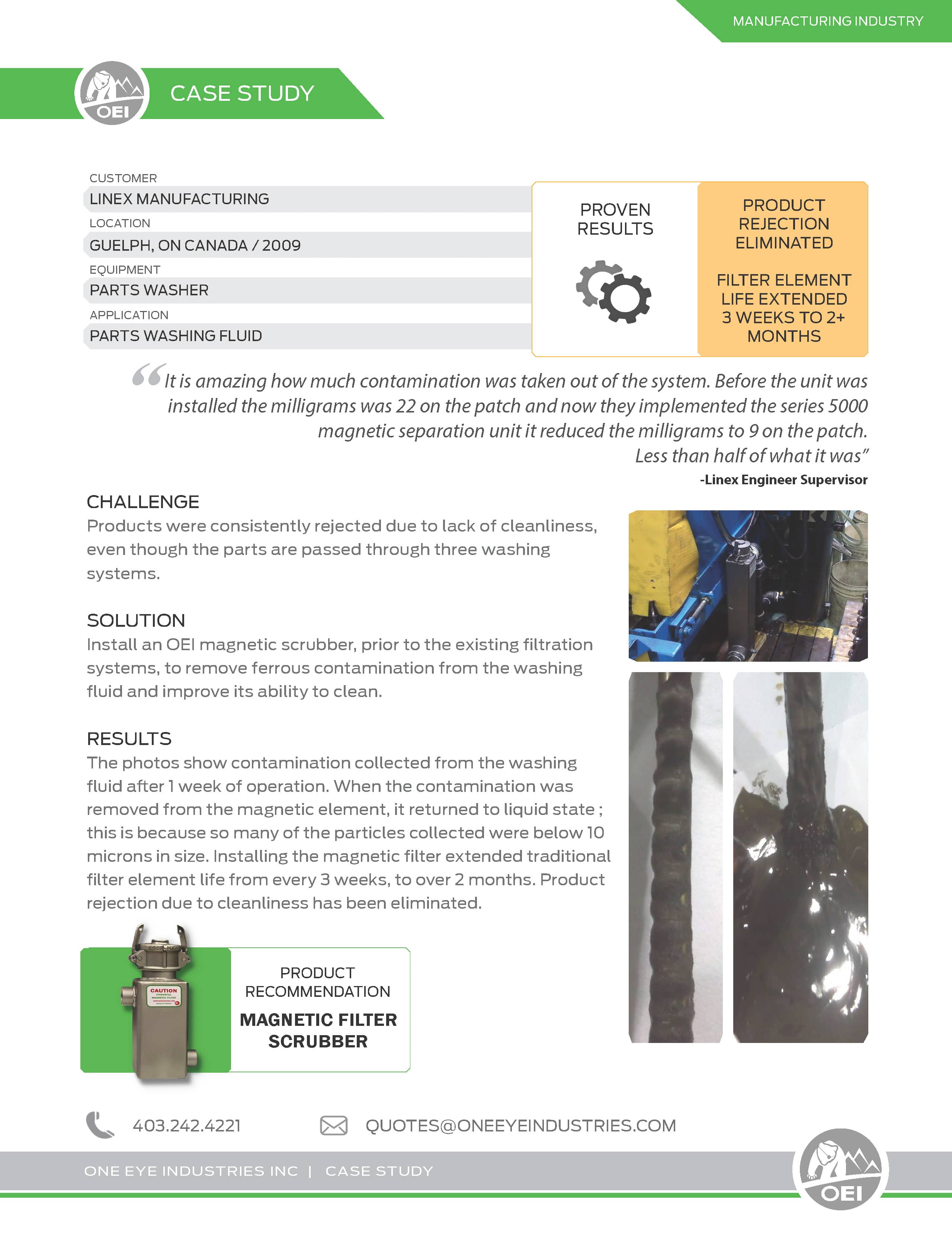

The photo shows contamination removed from the system after two weeks. The air flow is now clean, and the valves were re-installed. A similar amount of contamination is removed every three weeks during cleaning. If left in the system, these contaminants would continue to cause premature valve failure.

The annual savings realized from eliminating the replacement of 3 valves each month ($700/valve) can be equated to $25,000. This does not include the cost savings realized from preventing unscheduled downtime.

Manufacturing

RESULTS

Gearboxes and Transmissions

Lube Oil Reservoir Filtration

The challenge was to improve the Mobil 220 lube oil cleanliness to prevent unscheduled downtime and extend equipment life.

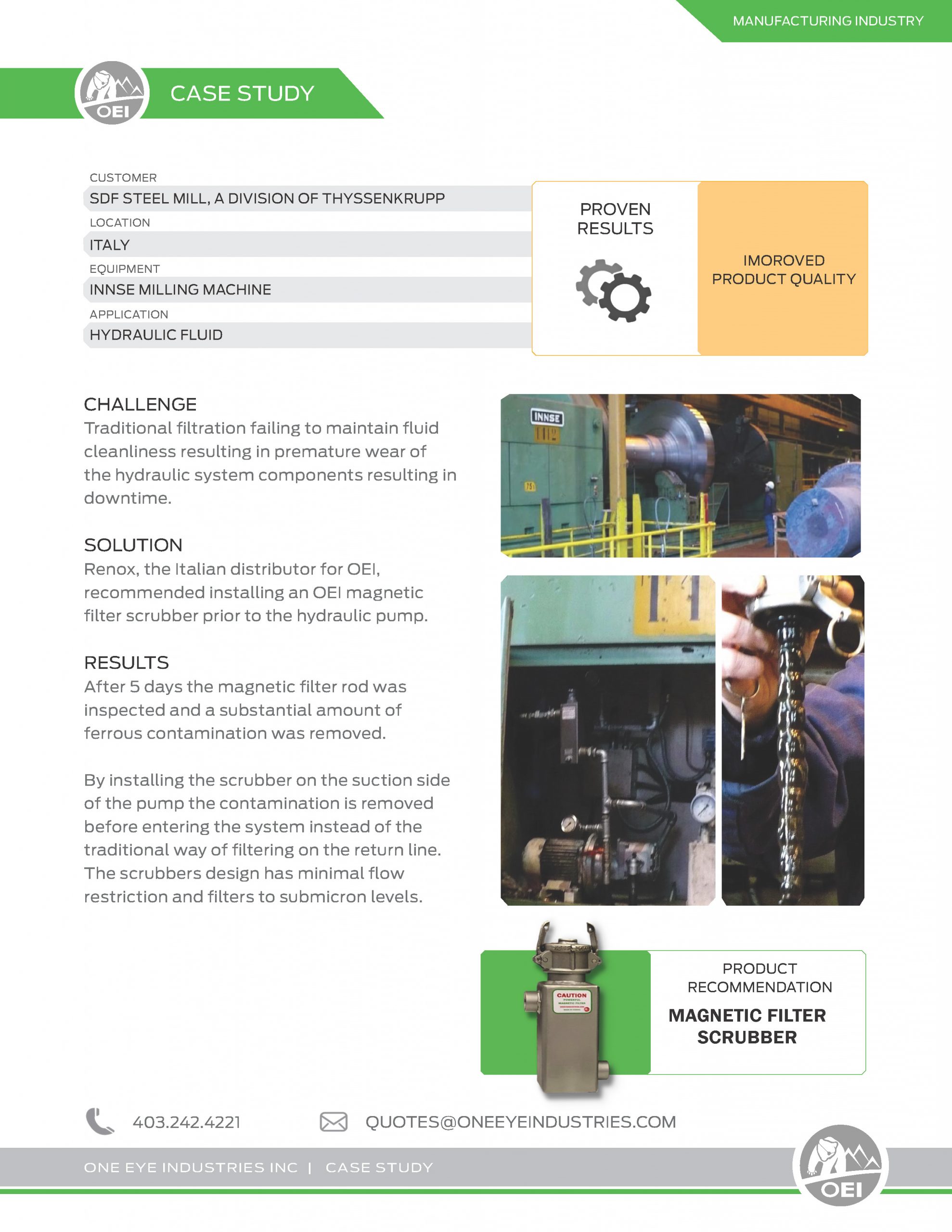

SDF Steel INNSE Milling Machine

Traditional filtration failing to maintain fluid cleanliness resulting in premature wear of the hydraulic system components resulting in downtime.

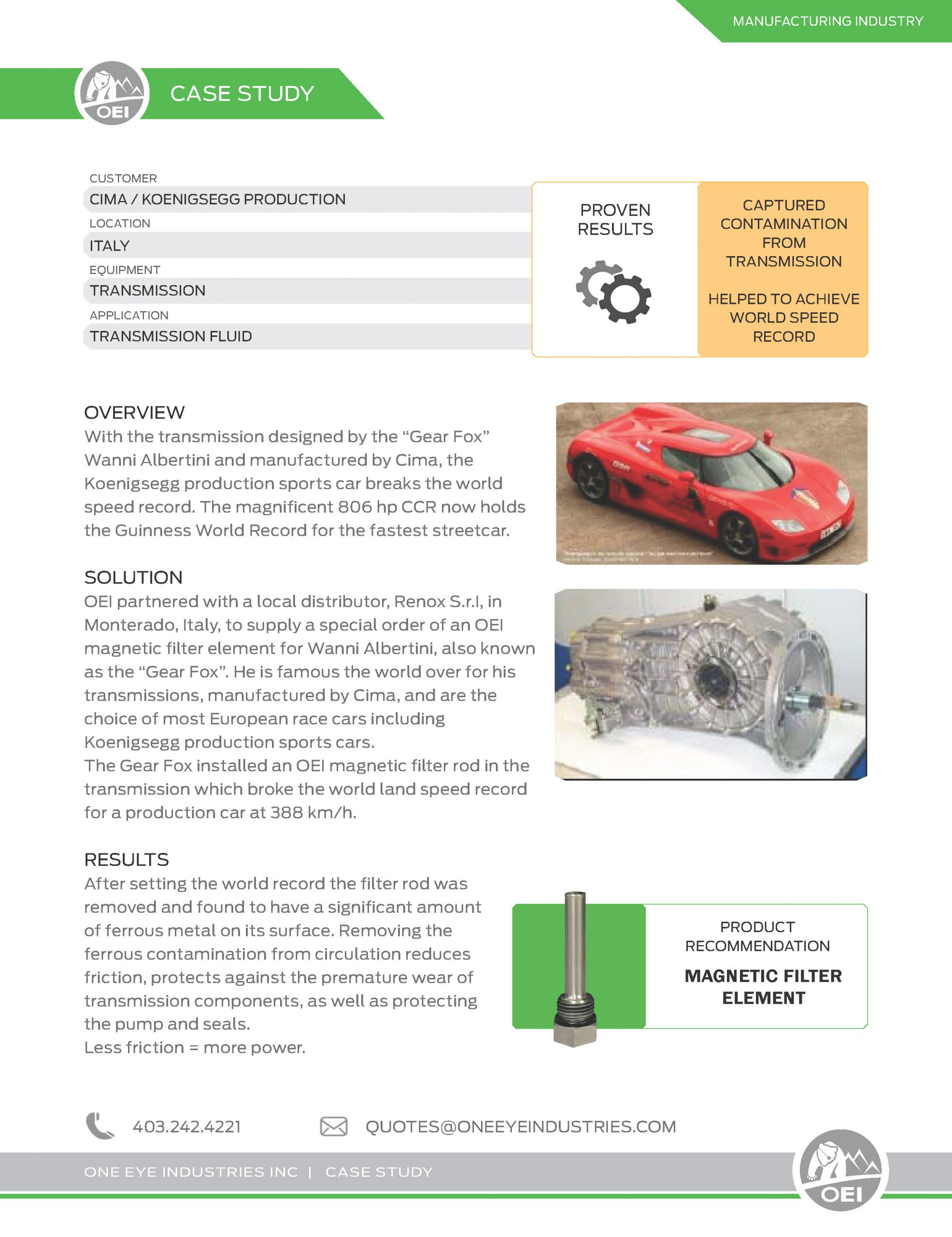

CIMA Race Car Transmission Fluid

With the transmission designed by the “Gear Fox” Wanni Albertini and manufactured by Cima, the Koenigsegg production sports car breaks the world speed record. The magnificent 806 hp CCR now holds the Guinness World Record for the fastest streetcar.

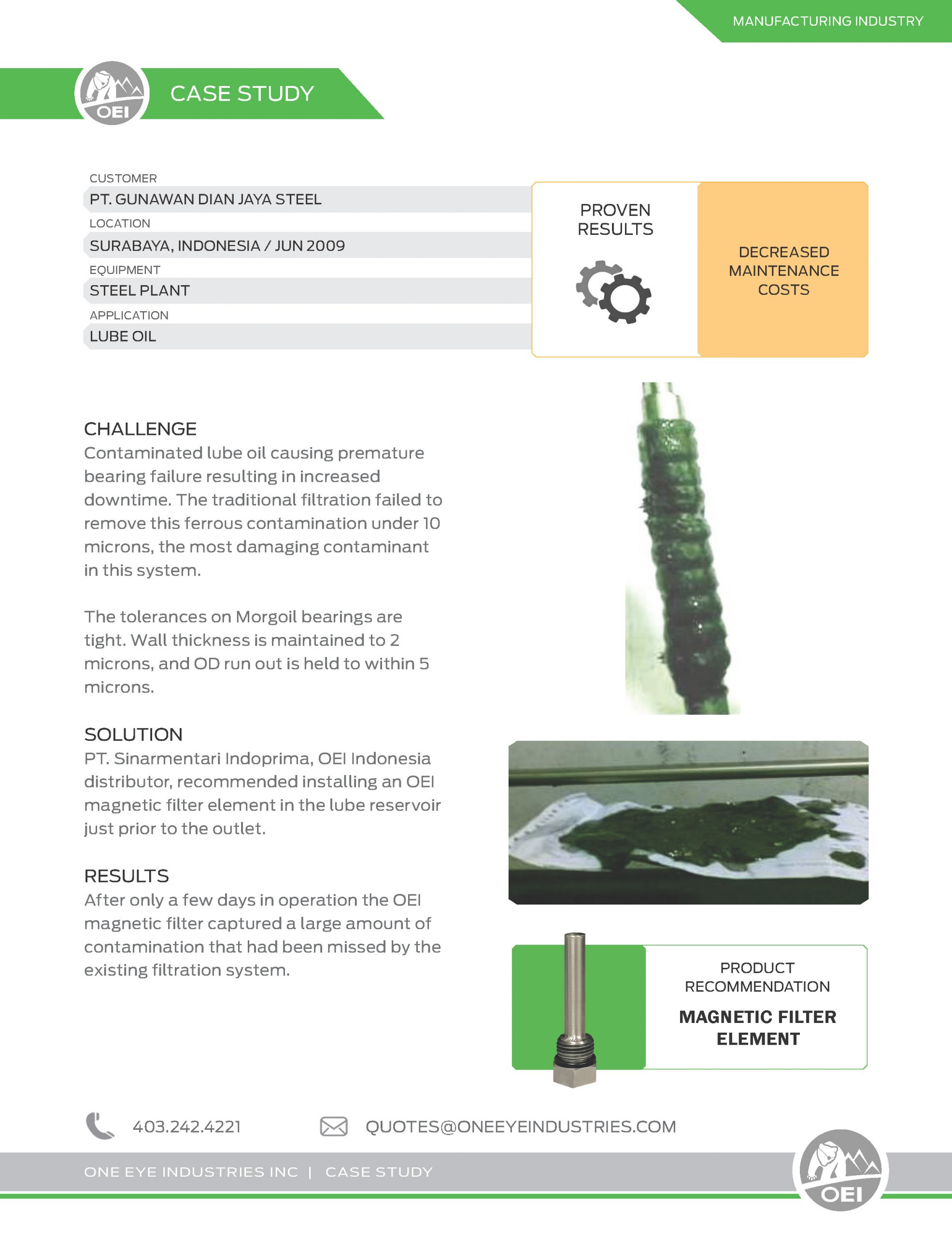

PT Gunawan Dian Jaya Steel Plant

Contaminated lube oil causing premature bearing failure resulting in increased downtime. The traditional filtration failed to remove this metal contamination under 10 microns, the most damaging contaminant in this system.

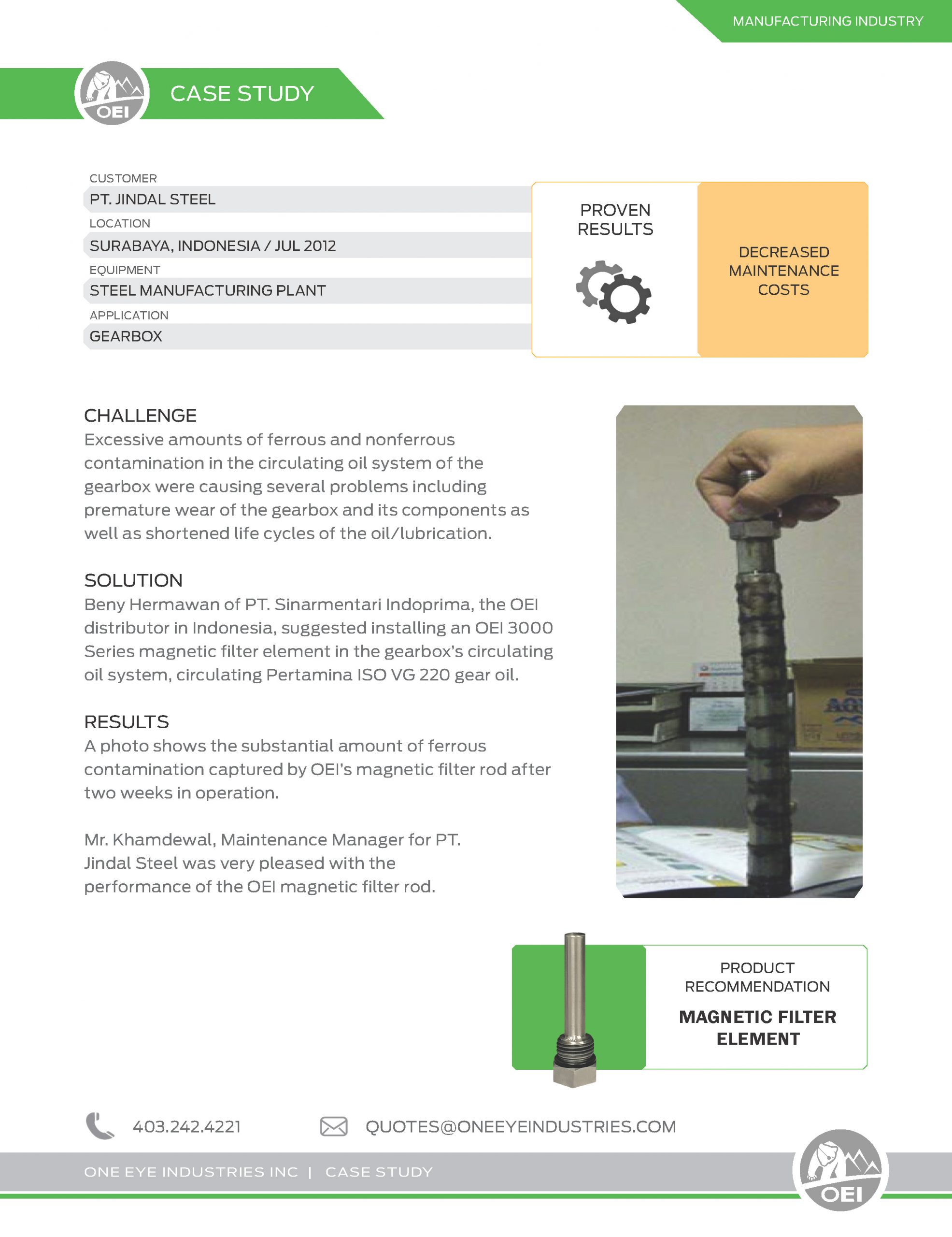

PT Jindal Steel Gearbox

Excessive amounts of ferrous and nonferrous contamination in the circulating oil system of the gearbox were causing several problems including premature wear of the gearbox and its components as well as shortened life cycles of the oil/lubrication.

Hydraulics and Pneumatics

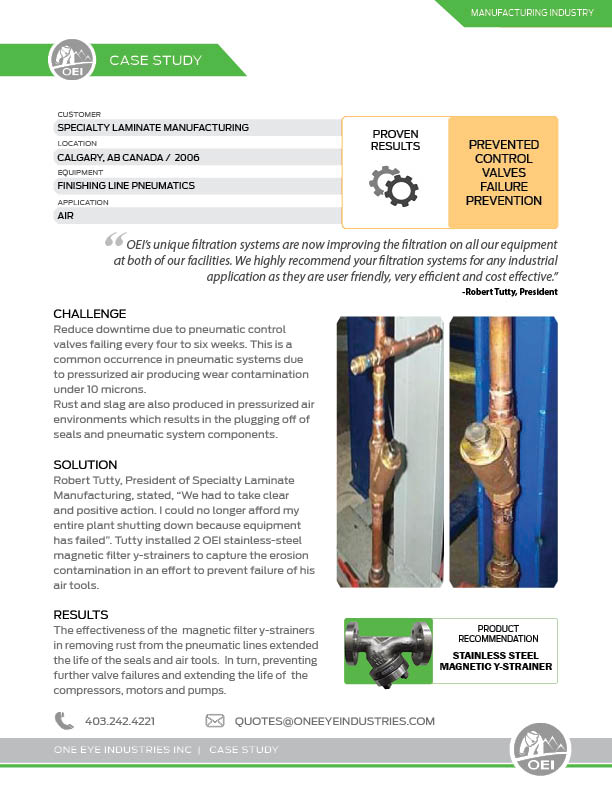

Finishing Line Pneumatic Control Valve Protection

The challenge was to reduce downtime due to pneumatic control valves failing every four to six weeks. This is a common occurrence in pneumatic systems due to pressurized air producing wear contamination under 10 microns. Rust and slag are also produced in pressurized air environments which results in the plugging off of seals and pneumatic system components.

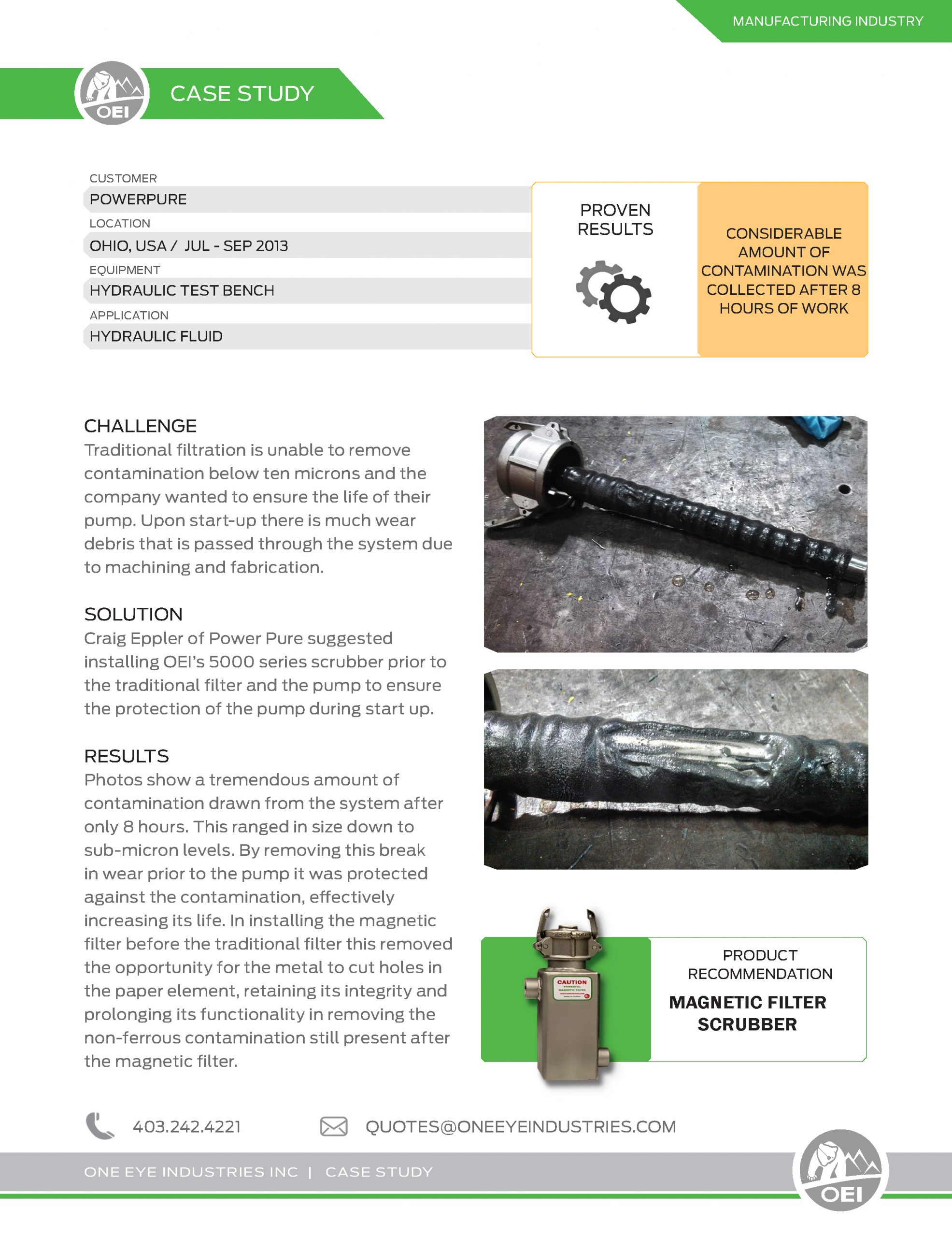

Powepure Hydraulic Test Bench

Traditional filtration is unable to remove contamination below ten microns and the company wanted to ensure the life of their pump. Upon start-up there is much wear debris that is passed through the system due to machining and fabrication.

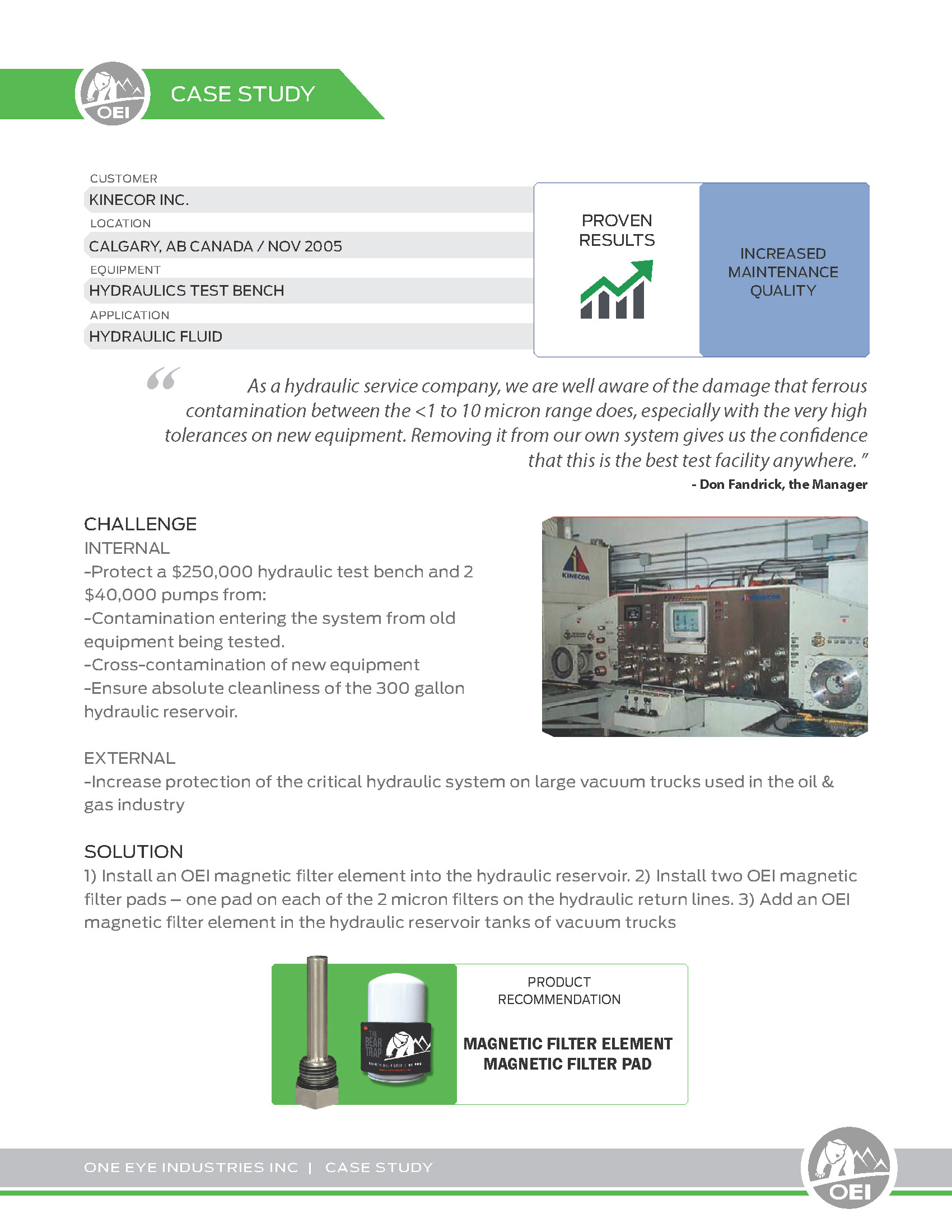

Kinecor Pump Hydraulic Test Bench

Kinecor offers their customers a hydraulic testing facility to ensure that serviced equipment is functioning properly. It is powered by an 8V92, 470 horse power, Detroit Engine and has a 300-gallon hydraulic reservoir. A 2-micron filter is installed at each of the two hydraulic returns to protect the $250,000 test system from older equipment, which typically has high levels of ferrous contamination.

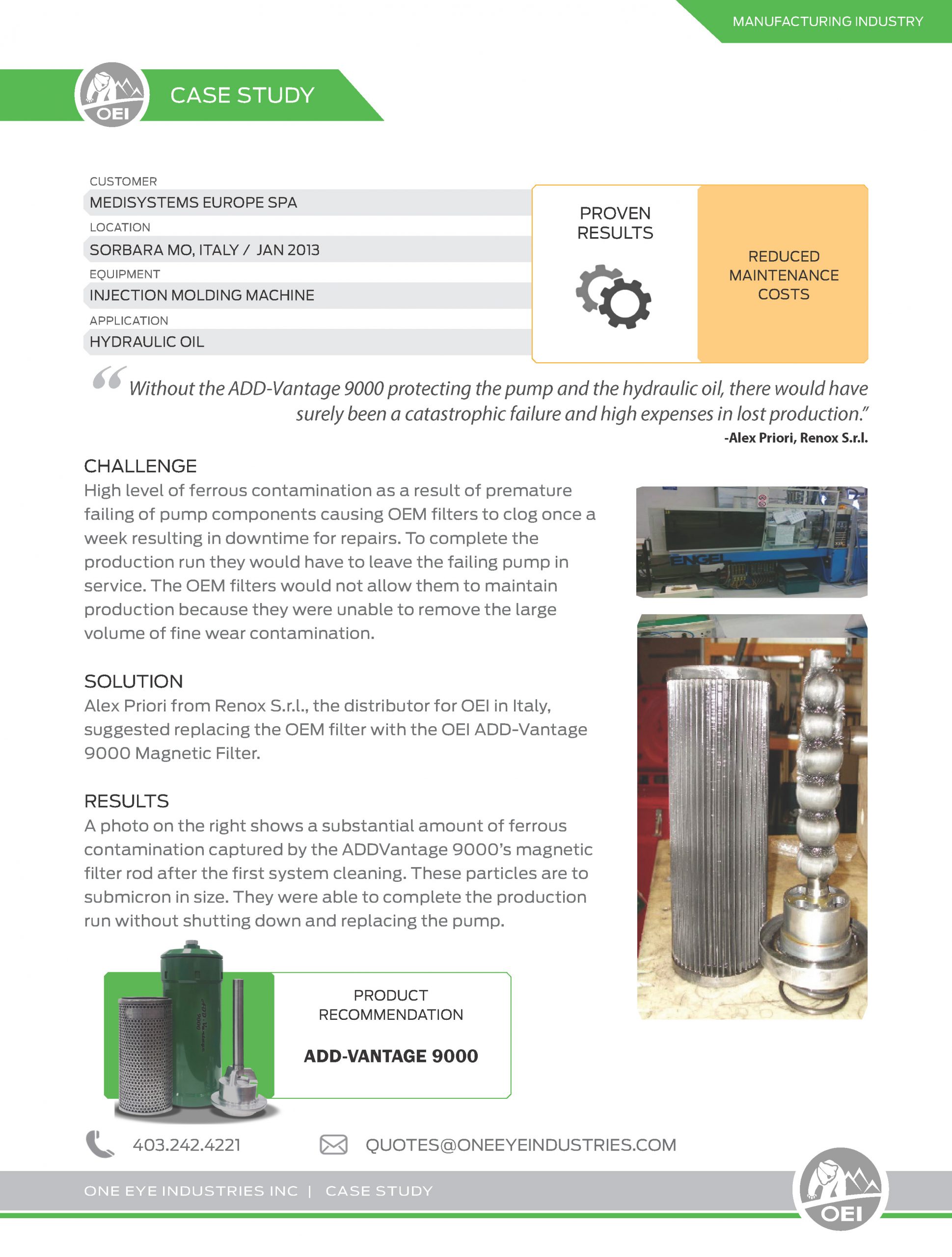

Medisystems Injection Molding Hydraulics

High level of ferrous contamination as a result of premature failing of pump components causing OEM filters to clog once a week resulting in downtime for repairs. To complete the production run they would have to leave the failing pump in service. The OEM filters would not allow them to maintain production because they were unable to remove the large volume of fine wear contamination.

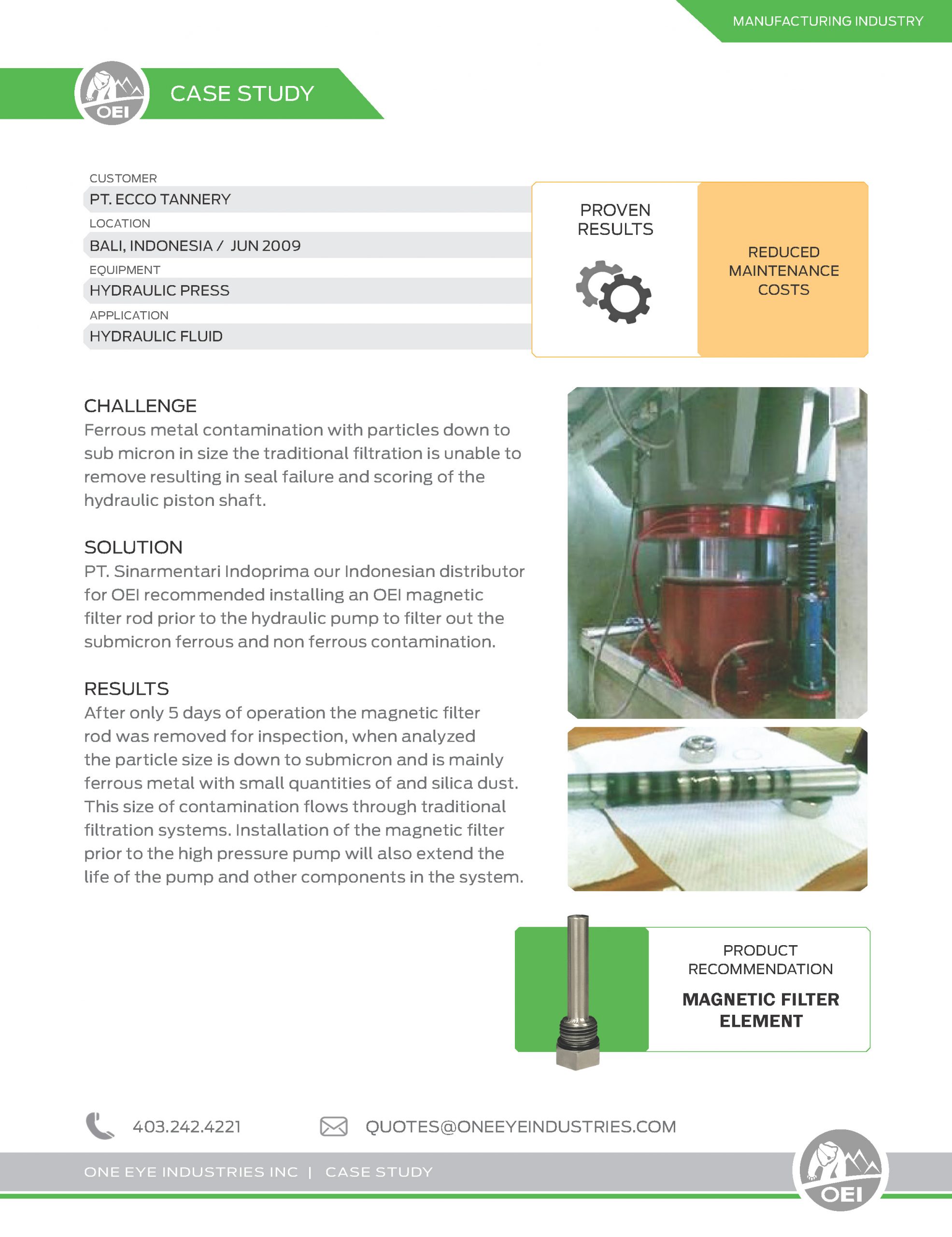

PT Ecco Tannery Hydrulic Press Shoe Factory

Ferrous metal contamination with particles down to sub micron in size the traditional filtration is unable to remove resulting in seal failure and scoring of the hydraulic piston shaft.

Specialty Laminate Wemhoner Hydraulic Press

Tutty approached One Eye Industries (0EI) with the hope that he could at least keep his 4,500-pound Wemhoner presses running without interruption. A OEI Magnetic Base filter rod was immediately installed at the inlet and the outlet of the Wemhoner’s 250-gallon hydraulic reservoir.

Ford Truck Factory Hydraulic Press

Install an OEI 24” Magnetic Filter Rod (3RNPT24ES) with protective screen. The screen is recommended because the length and location of the rod is near the exterior of the reservoir. If the rod were to attach to the reservoir removal would be problematic.

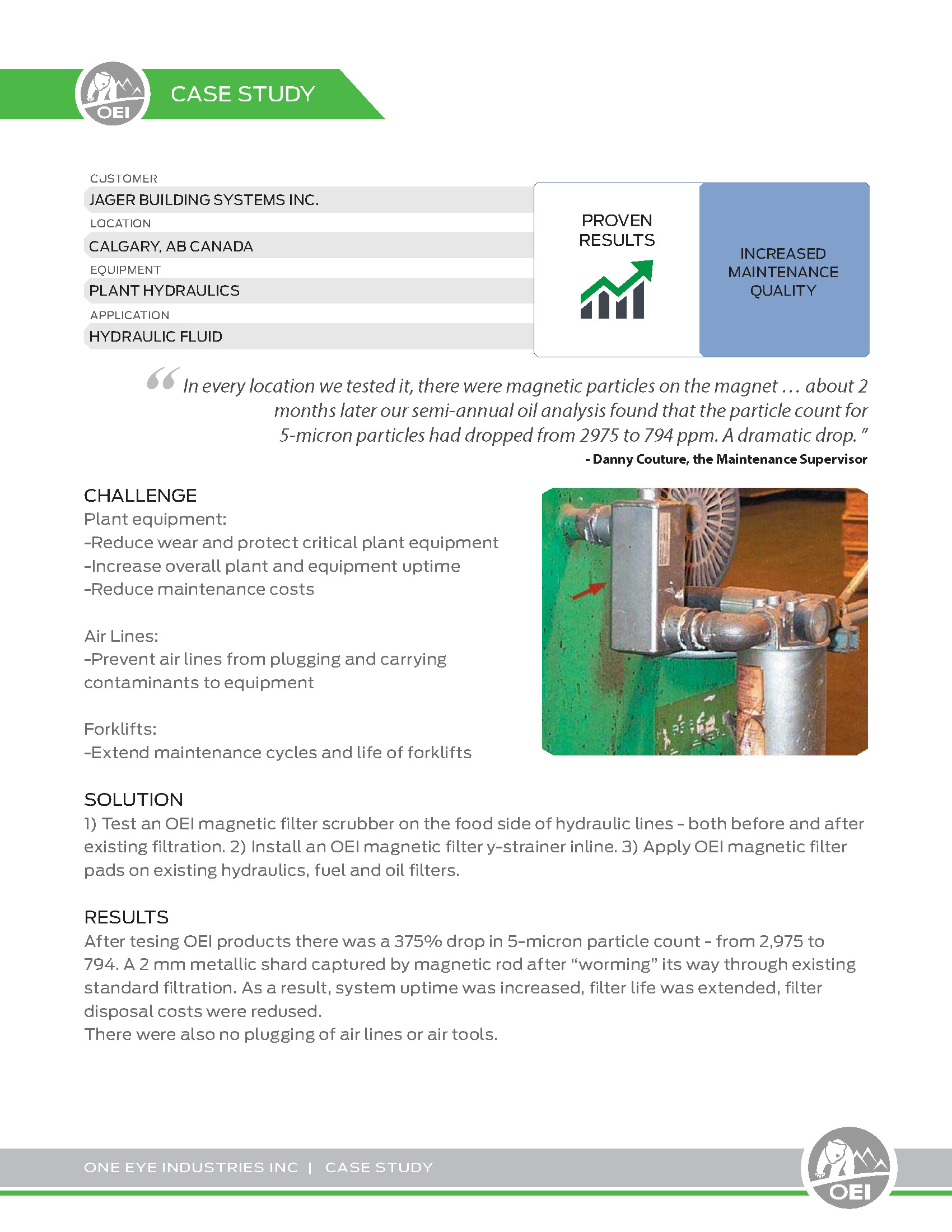

Jager Manufacturing Plant Hydraulics

375% drop in Ferrous Hydraulic Contaminants under 10 microns

One Eye Industries, specializing in longterm industrial filtration solutions, partnered to support the efforts of Jager’s plant maintenance program. Implementing a test study, JBS installed the FM4000 Scrubber on the feed side of plant hydraulic equipment before, and then after, their standard filtration systems to evaluate present filtration capabilities and effectiveness.

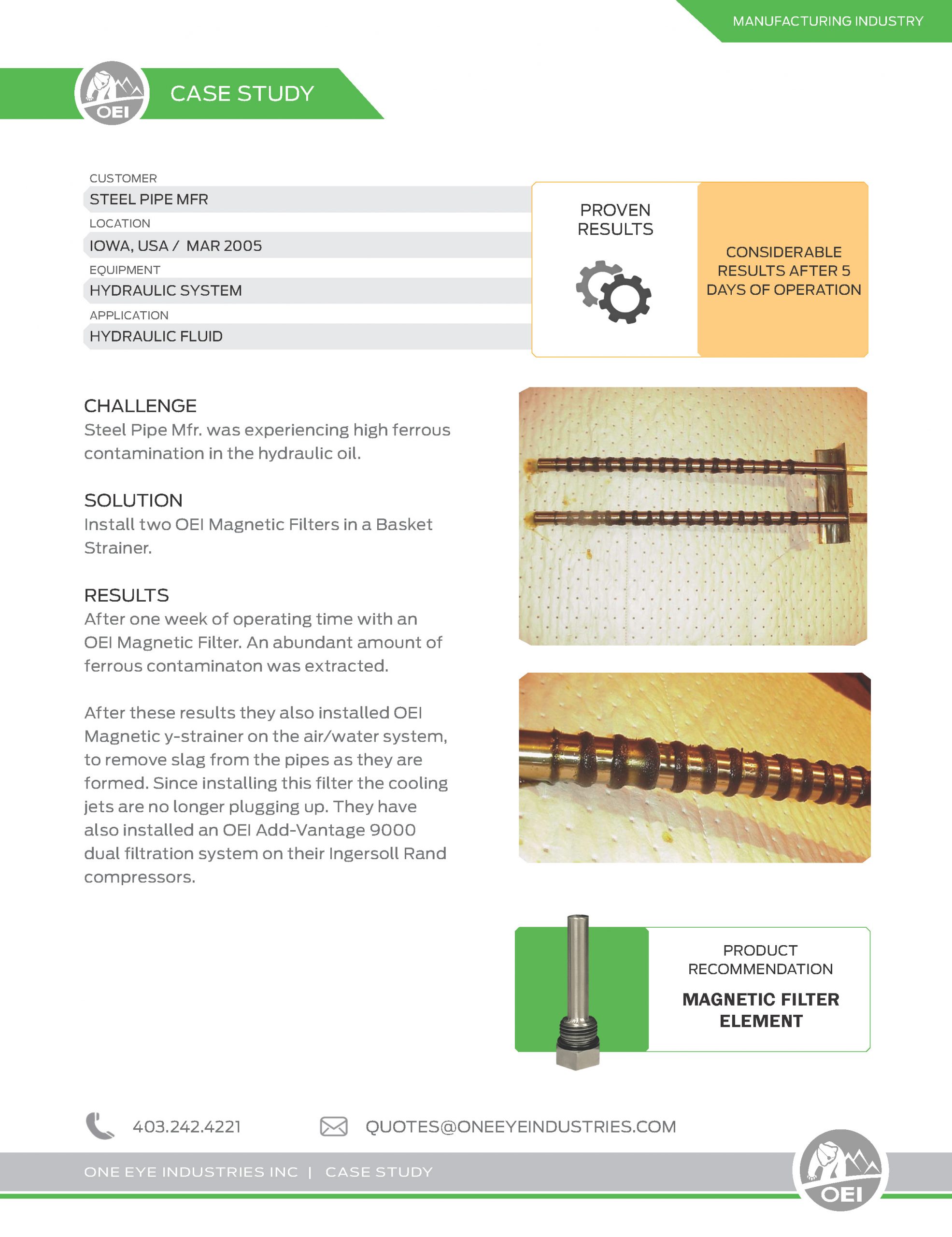

Hydraulic Filtration Steel pipe mfr

After one week of operating time with an OEI Magnetic Filter an abundant amount of ferrous metal was extracted. After these results they also installed OEI Magnetic y-strainer on the air/water system, to remove slag from the pipes as they are formed.

Parts Washers & Milling Machines

Gildermiester Milling Machine Cooling Fluid Filtration

The challenge was to prevent metal filings from filling the cooling system to avoid overheating and shutdown. The traditional filtration in the Gildermeister machine’s cooling system was not providing effective filtration and, therefore, the machine’s radiator was filling with metal filings. As a result, the machine was running at temperatures from 32-34 degrees Celsius (shut down would occur at 35 degrees). This was causing frequent unscheduled downtime for cooling system maintenance.

Ariston Parts Washer Quality Control

The challenge was to reduce contamination in the parts washing fluid to meet quality control cleanliness levels for painting.

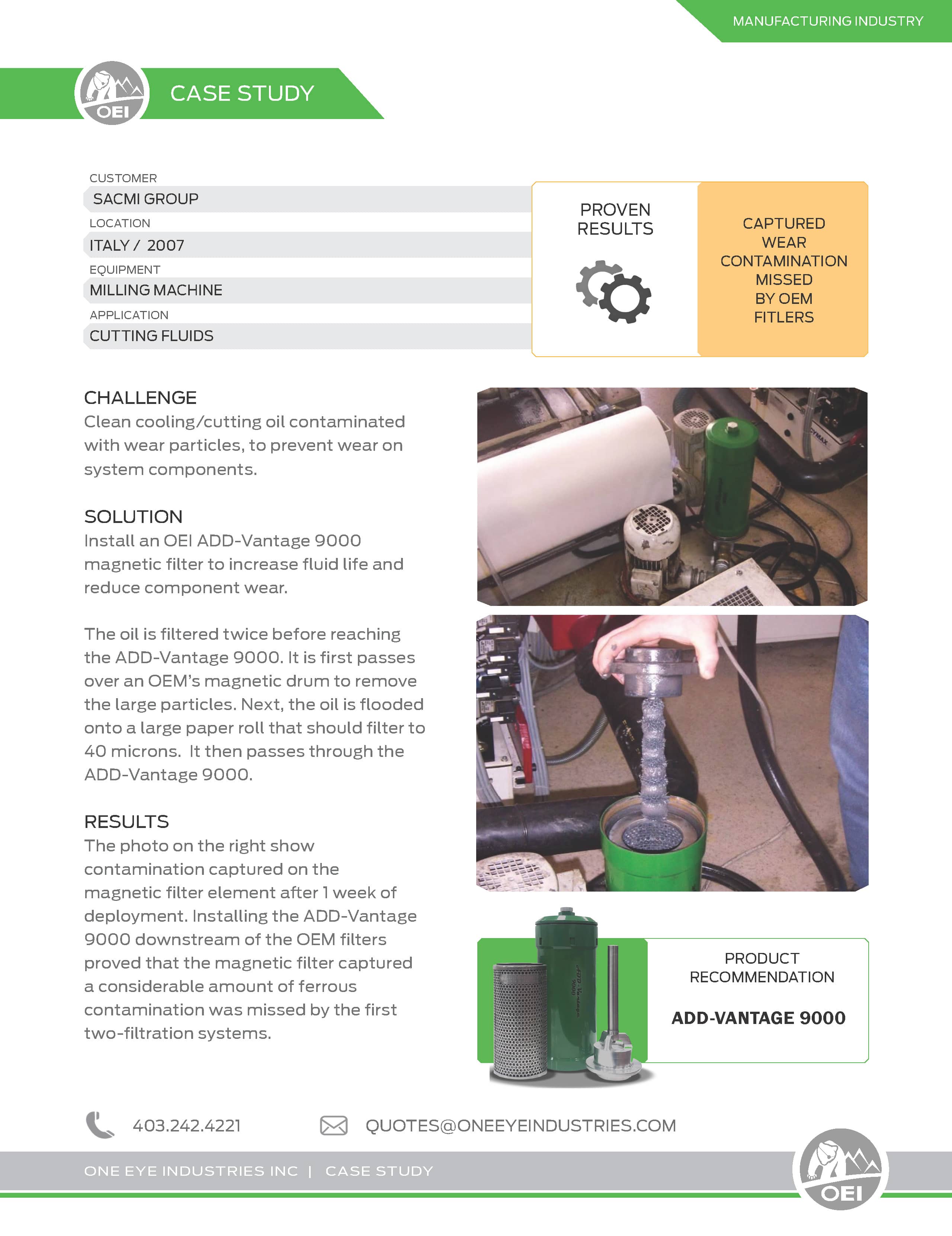

Improving SACMIs Cooling Cutting Fluid with Quality Filtration

The challenge was to clean cooling/cutting oil contaminated with wear particles, to prevent wear on system components.

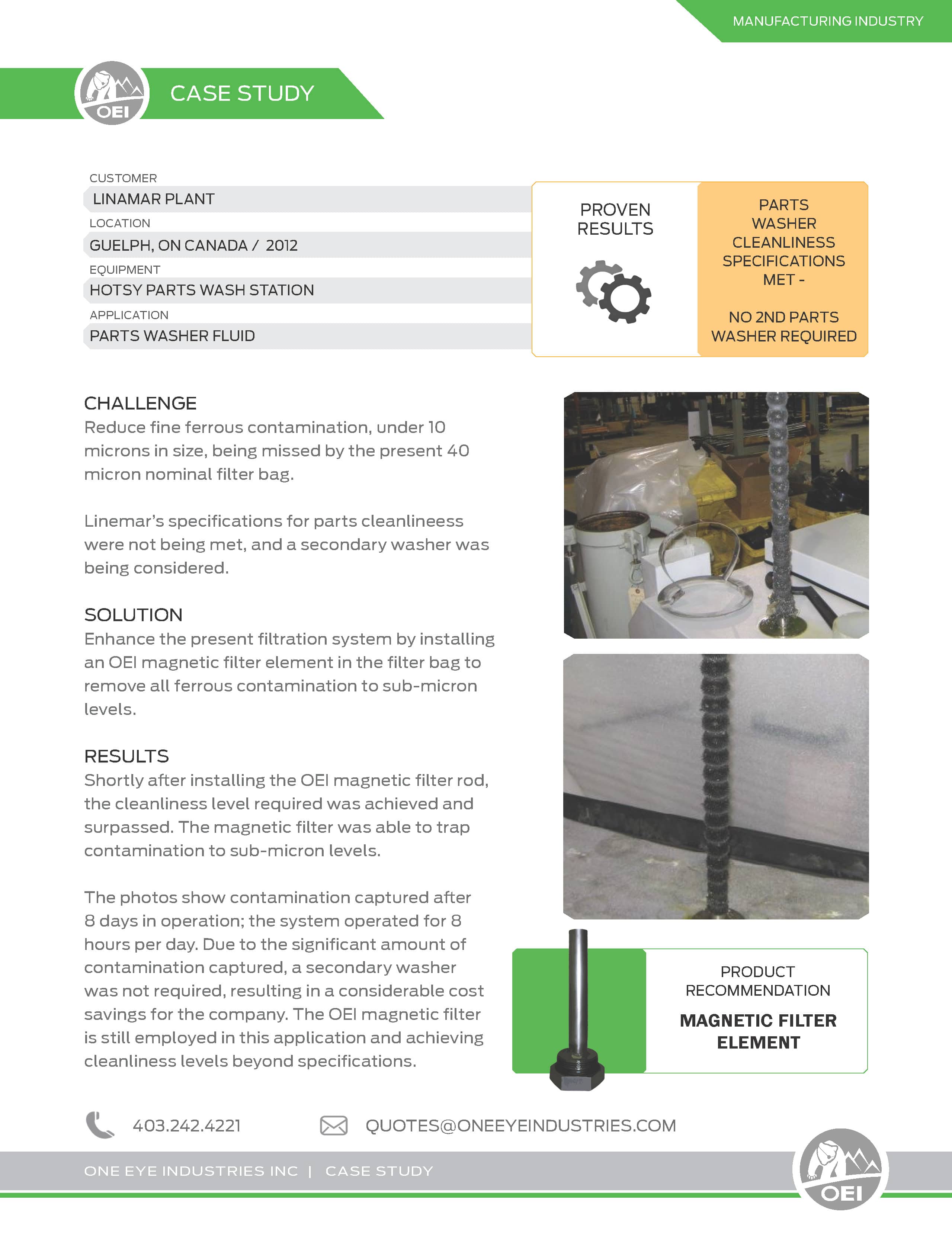

Improving Cleaning Capability of Linamar’s Hotsy Parts Washer

The challenge was to reduce fine ferrous contamination, under 10 microns in size, which was missed by 40 micron nominal filter bag. Linamar’s specifications for parts cleanliness were not met, and the secondary washer was considered.

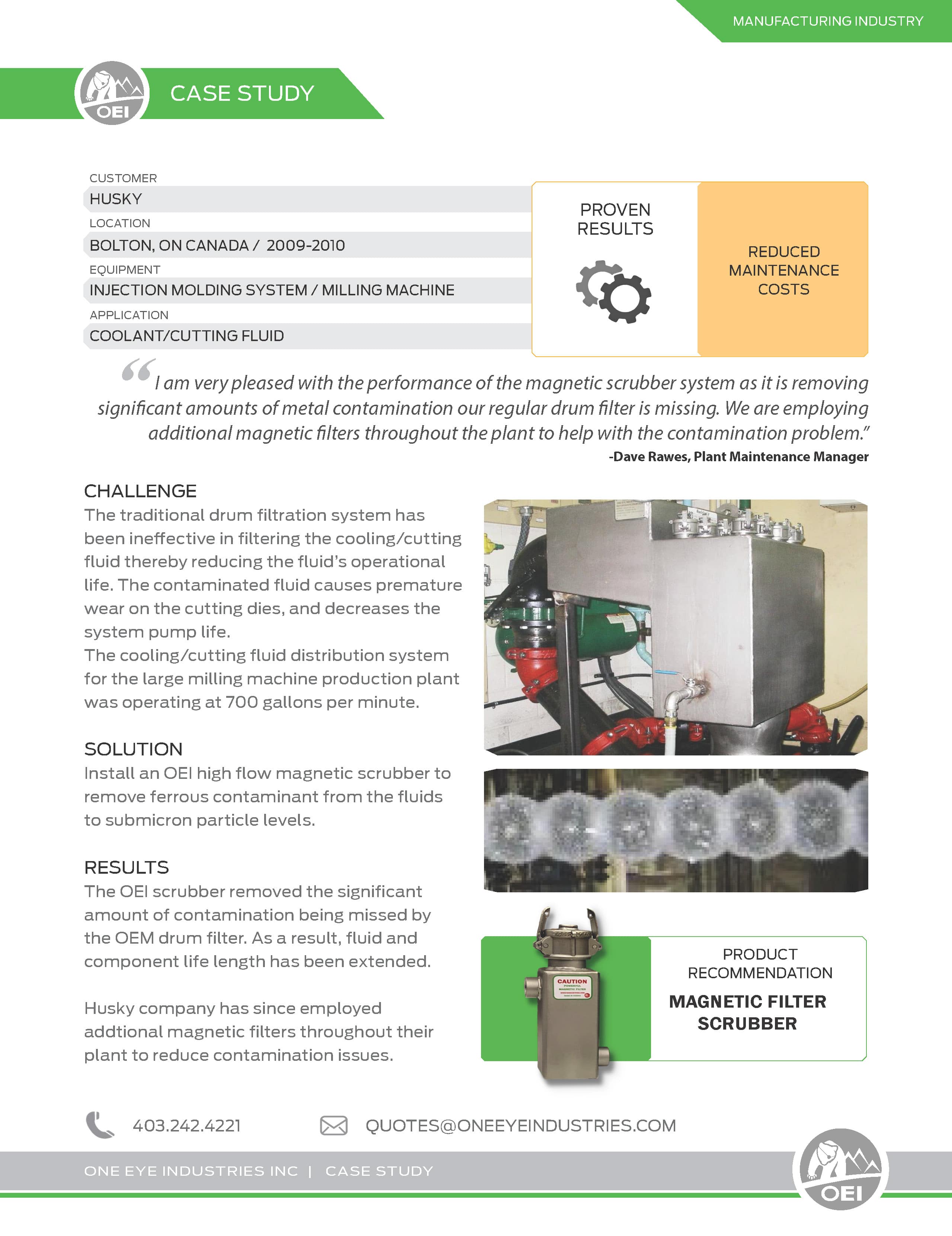

Husky’s Injection Molding System Protection

The traditional drum filtration system was ineffective in filtering the cooling/cutting fluid thereby reducing the fluid’s operational life. The contaminated fluid caused premature wear on the cutting dies, decreasing the system pump life. The challenge was to remove ferrous contaminant from the fluids to submicron particle levels.

Improving Linex Parts Washer Cleanliness

The challenge was to remove ferrous contamination from the washing fluid because products were consistently rejected due to lack of cleanliness, even though the parts are passed through three washing systems.

Danieli Corporation Cutting Coolants

The traditional filtration system (yellow arrow) was not cleaning the fluid efficiently thereby reducing the fluid life, prematurely wearing the tools and reducing production.

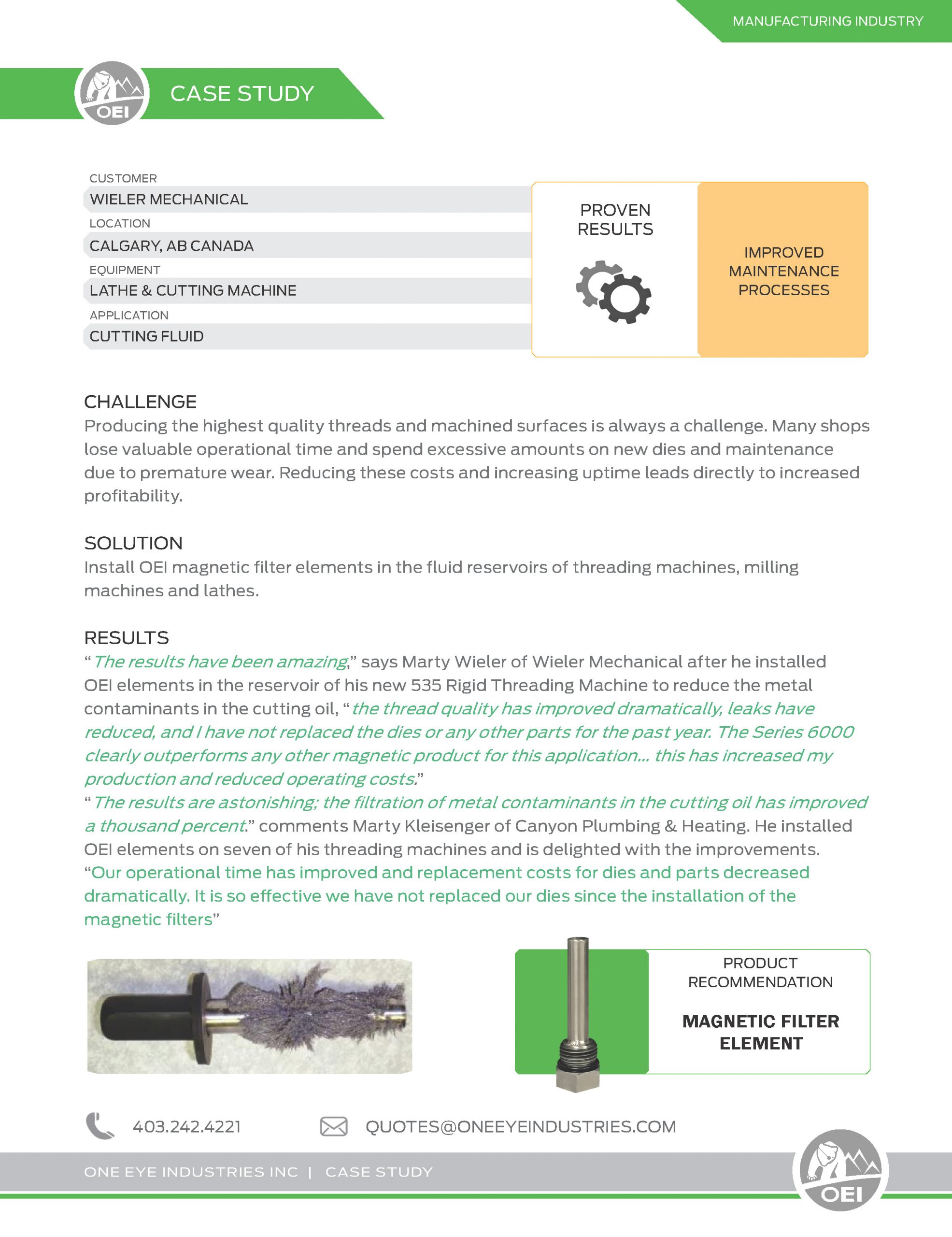

Wieler Mechanical Lathe & Cutting Machine

Producing the highest quality threads and machined surfaces is always a challenge. Many shops lose valuable operational time and spend excessive amounts on new dies and maintenance due to premature wear. Reducing these costs and increasing uptime leads directly to increased profitability.

Compressors

Ingerssol High-Pressure Air Compressor

Moisture in the air system was causing corrosion of the carbon-steel piping was producing high levels of contamination in the system. The contamination was prematurely damaging the solenoid valve rubber seals. The damage forced the valves to remain open resulting in the need to replace them monthly. The valve failures were inhibiting production. In an effort to reduce unscheduled downtime and the monthly expense of replacing the valves, the maintenance team removed them all together.

Water Systems

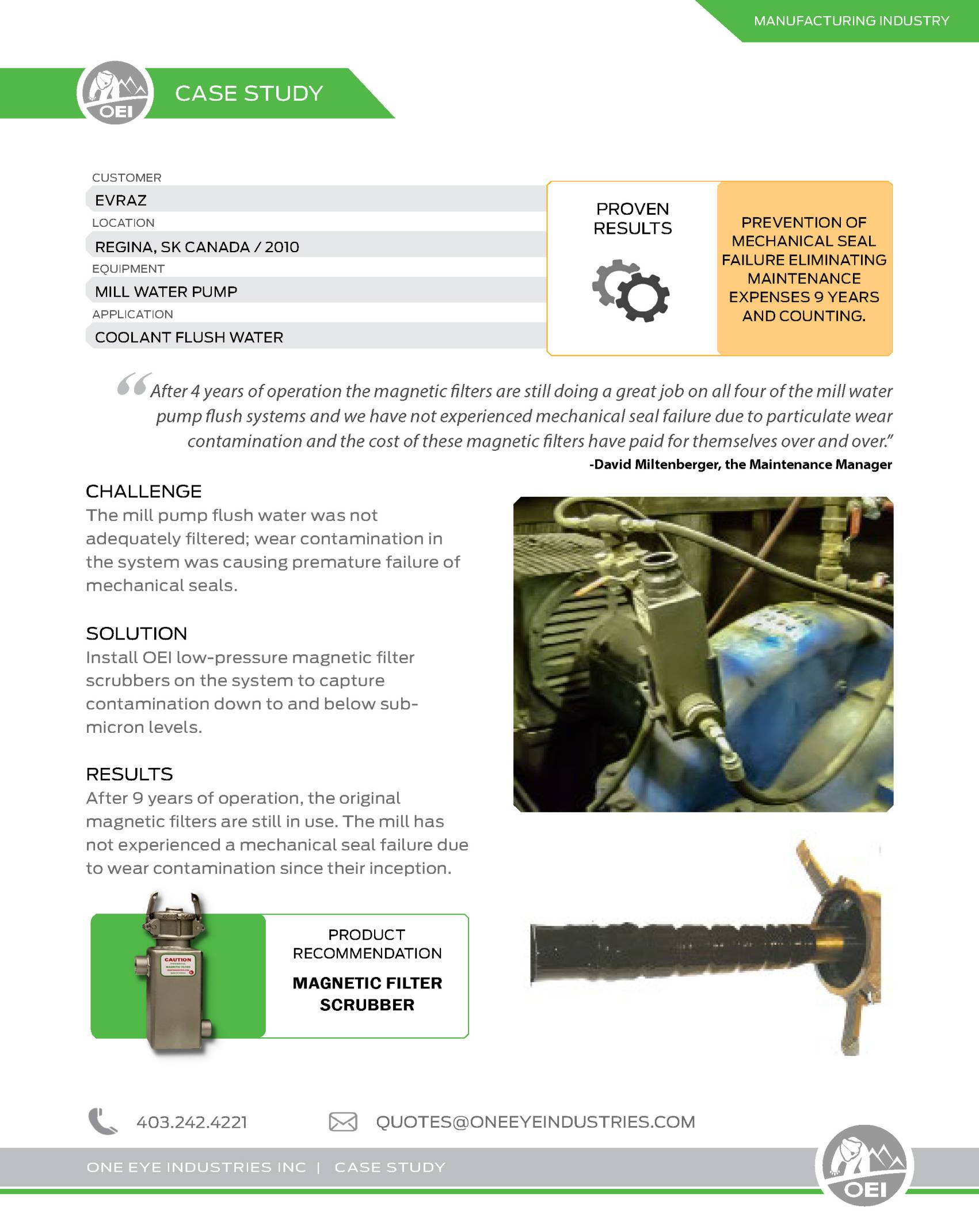

Evraz Coolant Flush Water Mechanical Seals

The mill pump flush water was not adequately filtered; wear contamination in the system was causing premature failure of mechanical seals.

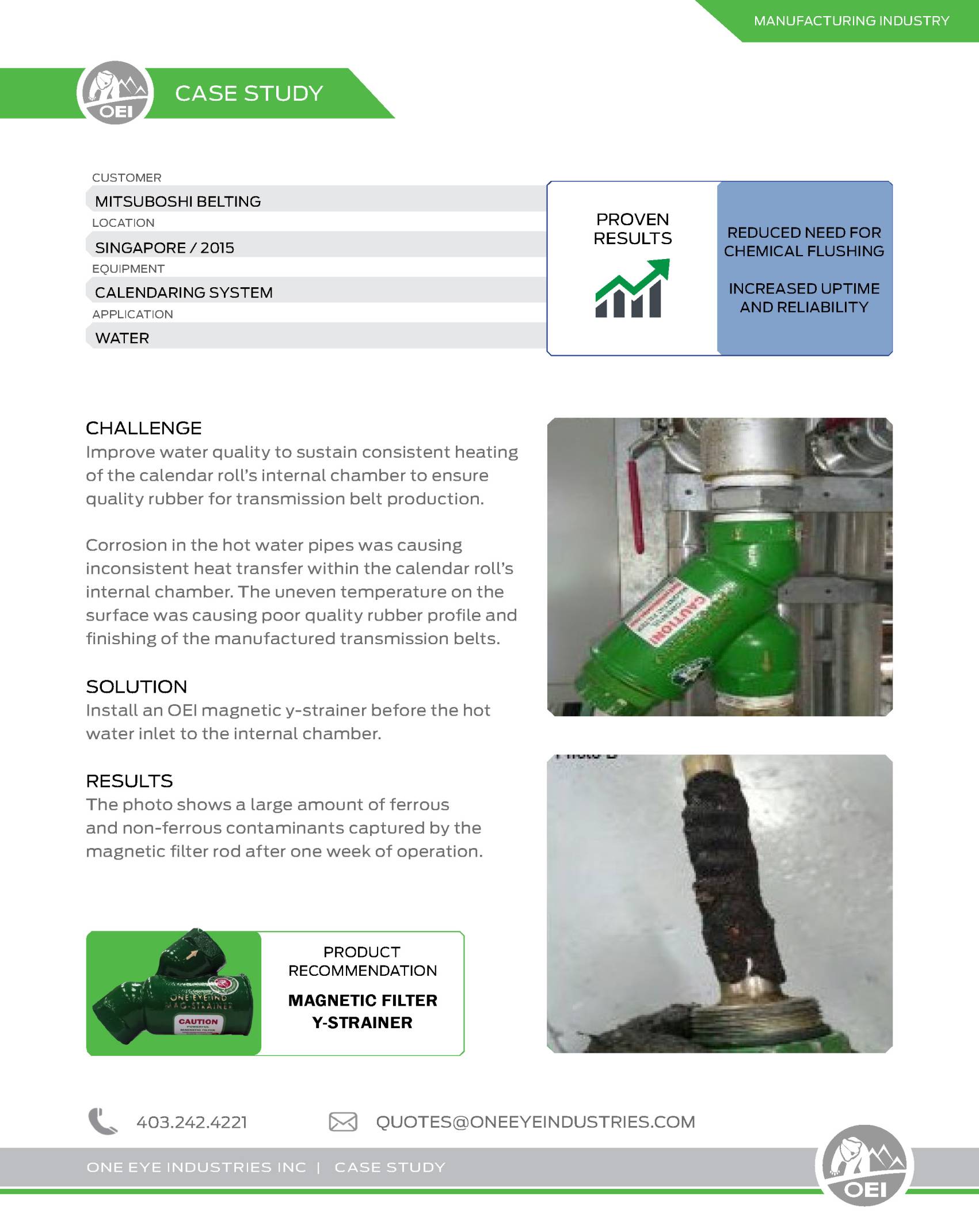

Mitsuboshi Belting Calendaring Hot Water System

The challenge was to improve water quality to sustain consistent heating of the calendar roll’s internal chamber to ensure quality rubber for transmission belt production.

Corrosion in the hot water pipes was causing inconsistent heat transfer within the calendar roll’s internal chamber. The uneven temperature on the surface was causing poor quality rubber profile and finishing of the manufactured transmission belts.

Gun Powder Plant Process Water

Improve the quality of facility process water to meet municipal standards. This facility uses municipal water in the manufacturing of it’s gun powder. String filters were ineffective in removing the contamination caused by corrosion of the facilities’ carbon-steel piping and systems. The rust contamination resulted in the facility process water failing to meet municipal water quality standards.

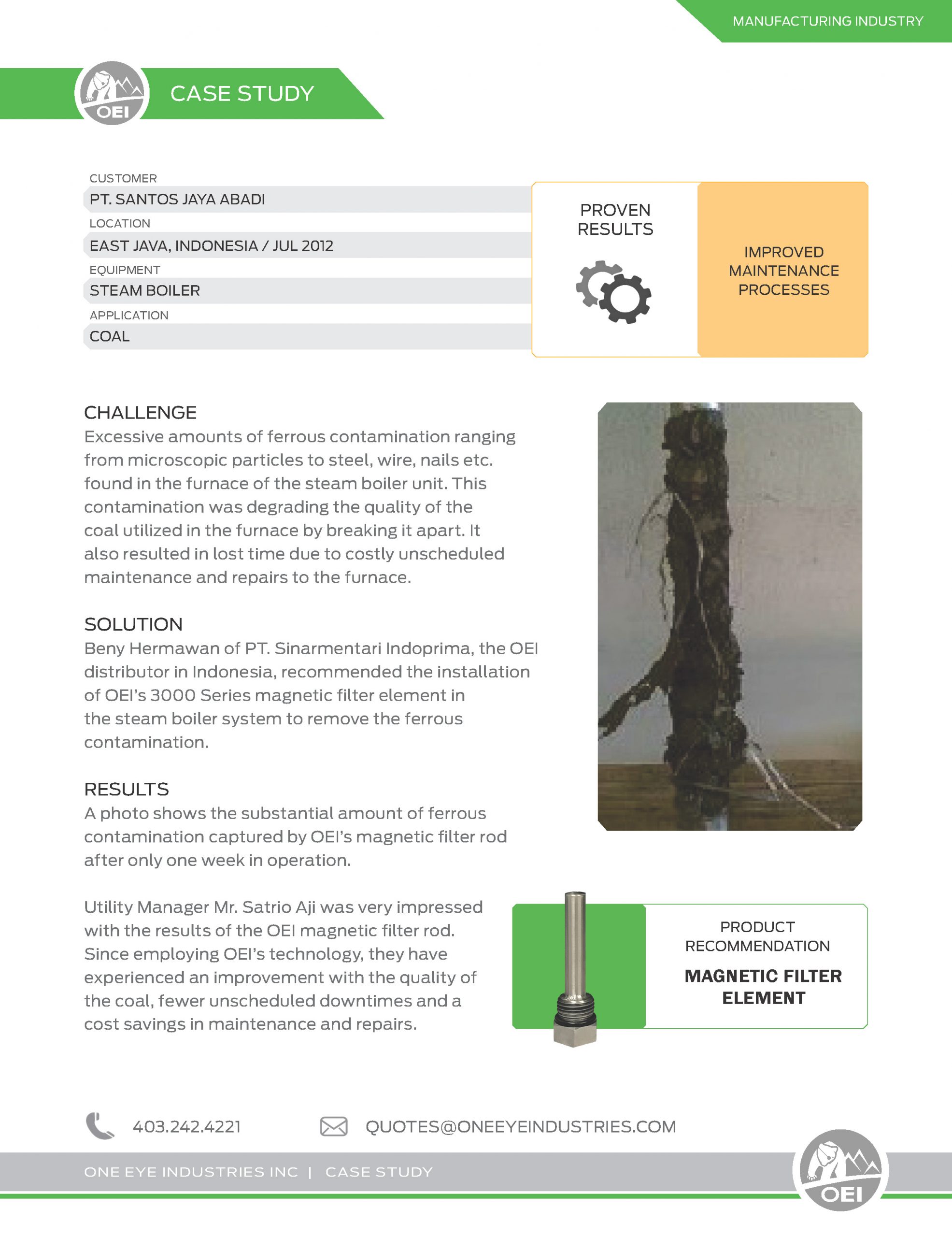

PT Santos Jaya Abadi Coal Fuel

Excessive amounts of ferrous metal contamination ranging from microscopic particles to steel, wire, nails etc. found in the furnace of the steam boiler unit. This contamination was degrading the quality of the coal utilized in the furnace by breaking it apart. It also resulted in lost time due to costly unscheduled maintenance and repairs to the furnace.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product is right for you

REQUEST A QUOTE

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com