Mining

Equipment reliability is the primary cost consideration for mining operations. Mobile equipment costs are ever increasing from operation, labour requirements, and capital investment of replaceable fluids, filters and failed components. OEI cleanable magnetic filters are proven to maximize equipment uptime and operating life to improve business impact.

Feature Case Study

ROI: Engine Rebuild Preventions, $1,450,000

Customer

Gold Mine

Location

Papua New Guinea / 2018 – Ongoing

Equipment

CAT 739D Haul Trucks

Application

Engine Oil

Problem

The CAT 789D haul trucks being used at a gold mine in Papua New Guinea were experiencing frequent engine failures due to wear contamination damaging tight-tolerance engine components. The mine required a solution for equipment downtime and lost productivity.

Solution

Begin a 2 year trial deploying OEI ADD-Vantage 9000 engine oil filters on 6 haul trucks.

Results

The results were so compelling that after only 1 year the mine outfitted an additional 36 haul trucks with the OEI ADD-Vantage 9000 filters.

In 1 year, the OEI filters saved the mining operation $1,450,000 in engine rebuild preventions and extended oil intervals.

The mine intends to outfit their full fleet of CAT 789D haul trucks with OEI filters to protect their coolant systems, engines, hydraulics, wheel motors and fuel systems.

Mining

RESULTS

Mobile Equipment

Engine Coolant

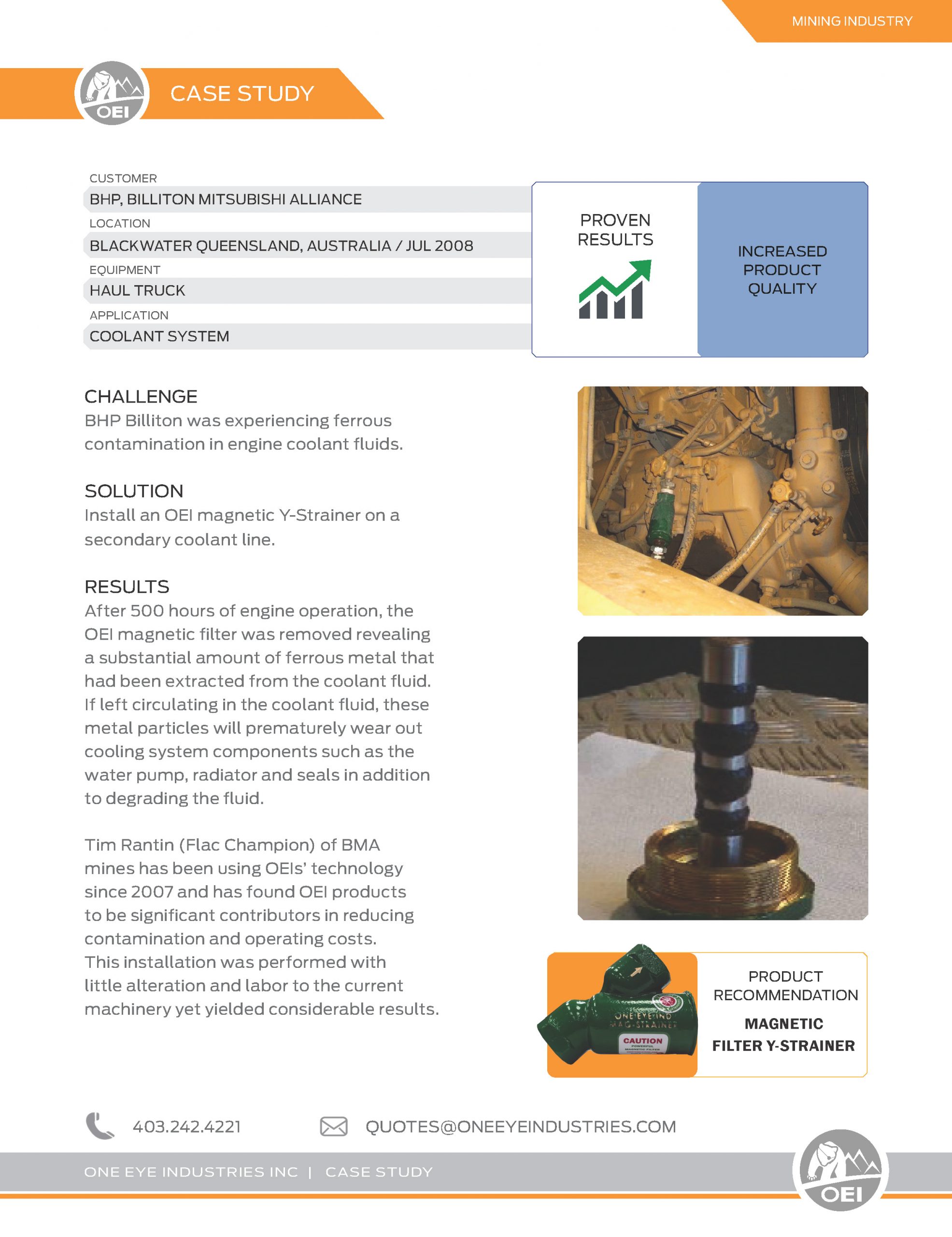

BHP Billiton Mitsubishi Blackwater Mine Haul Truck Coolant

After 500 hours of engine operation, the OEI magnetic filter was removed revealing a substantial amount of ferrous metal that had been extracted from the coolant fluid (see Photo B). If left circulating in the coolant fluid, these metal particles will prematurely wear out cooling system components such as the water pump, radiator and seals in addition to degrading the fluid.

Engine Fuel

Surface Lignite Mine Diesel Tank Flushing

The presence of contamination in the diesel fuel tank causes damage to fuel system components including the circulation pump. Traditional filtration is unable to remove the most damaging contamination (below 10 microns) effectively causing premature wear of the injectors, actuators, and camshaft.

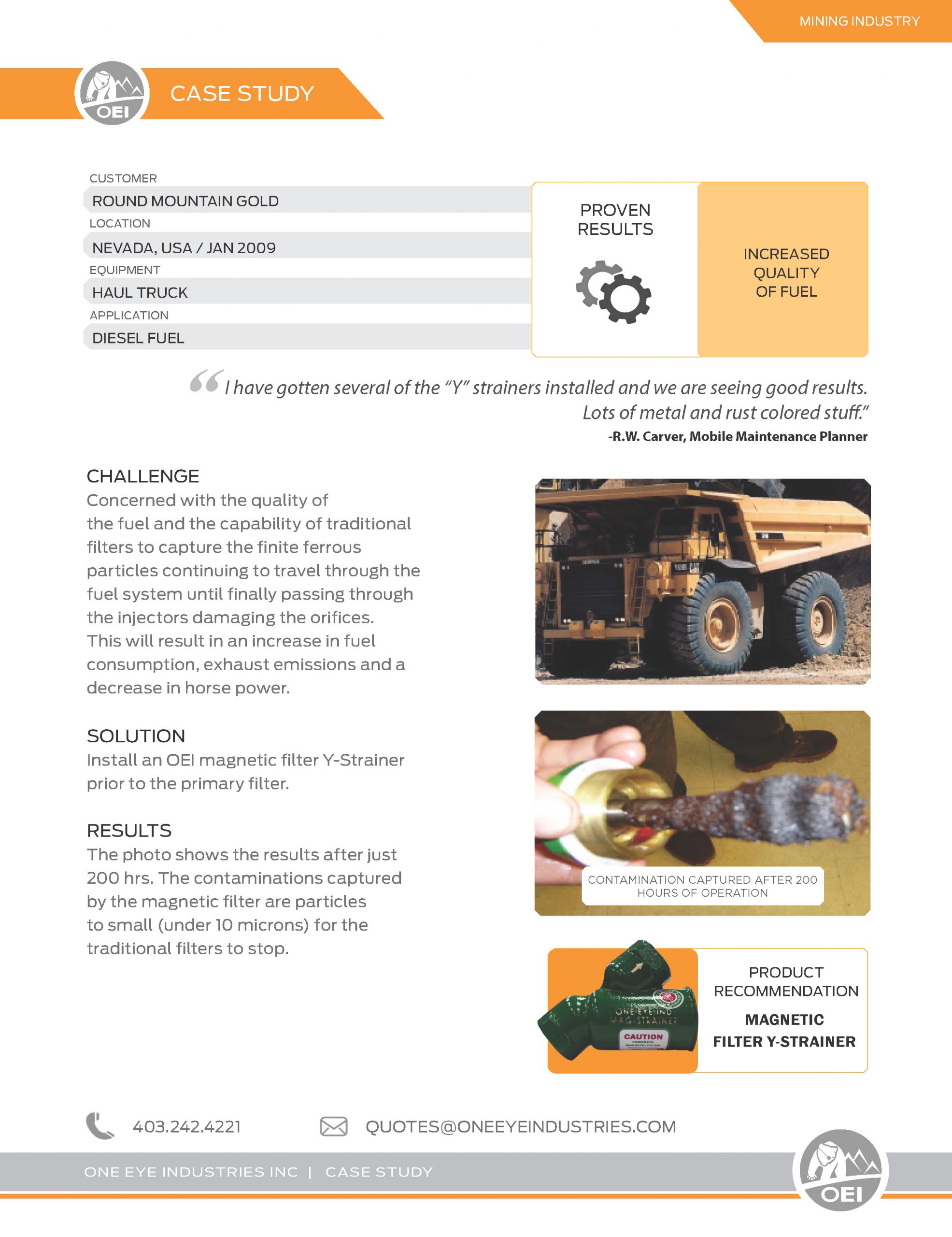

Round Mountain Mine Haul Truck Diesel Fuel

Concerned with the quality of the fuel and the capability of traditional filters to capture the finite ferrous particles continuing to travel through the fuel system until finally passing through the injectors damaging the orifices. This will result in an increase in fuel consumption, exhaust emissions and a decrease in horse power.

Engine Lube Oil

36 Haul Truck Engines & 1.5 Million Dollar Savings

The challenge was to extend engine oil change interval and rebuild times. The CAT 785D haul trucks at a gold mine were experiencing frequent engine failures due to wear contamination. The mine required a solution for equipment downtime and lost productivity.

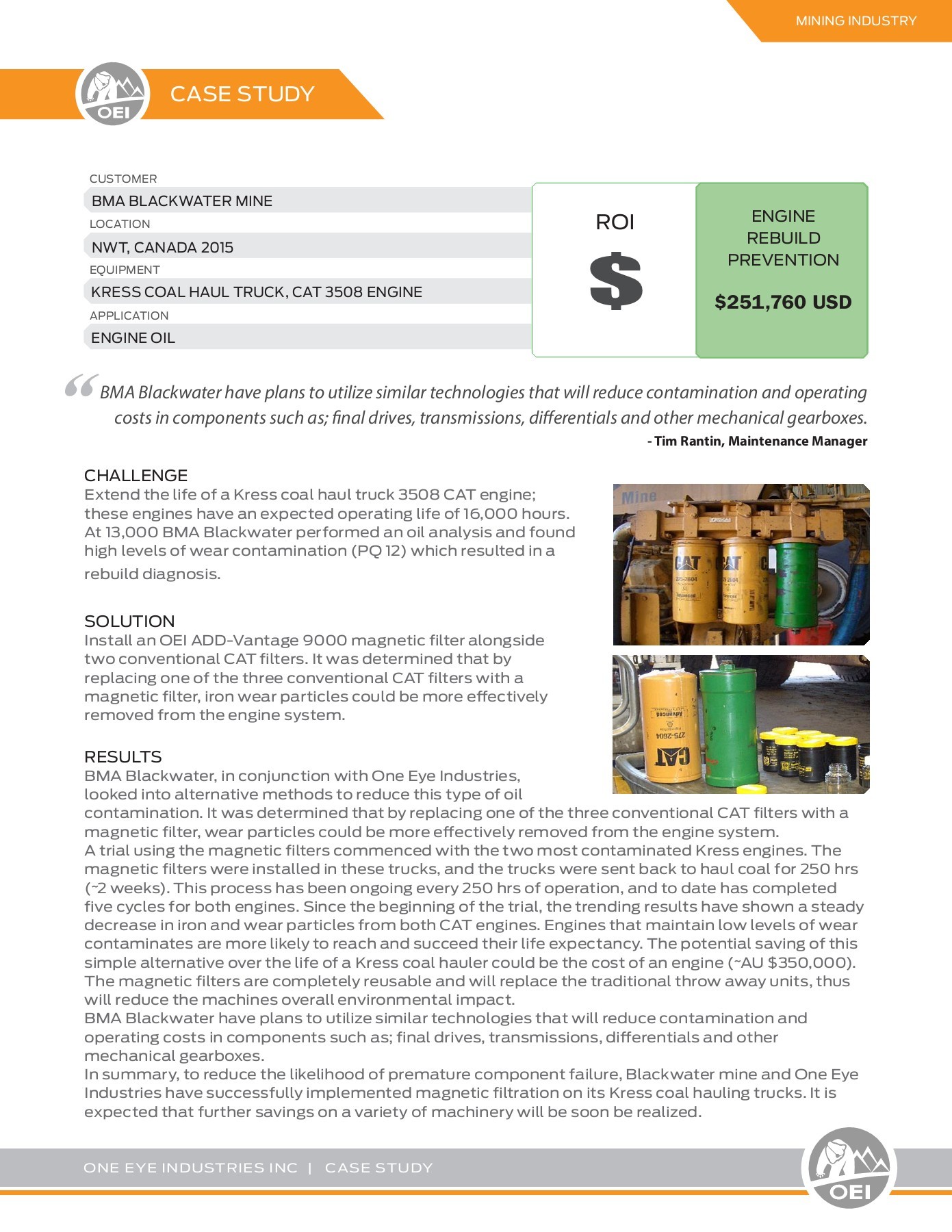

Cancelling the Rebuild of a CAT 3508 Haul Truck Engine

The challenge was to extend the life of a Kress coal haul truck 3508 CAT engine; these engines have an expected operating life of 16,000 hours. At 13,000 BMA Blackwater performed an oil analysis and found high levels of wear contamination (PQ 12) which resulted in a rebuild diagnosis.

Gearboxes and Transmissions

Prevent Final Drive Failure fo a C10 & C11 Dozer Fleet

A leading coal producer in Australia’s Bowen basin wanted to extend the service intervals of their dozer fleet from 250 hours to 330 hours. The OEM CAT magnetic filter plugs were unable to remove enough wear contamination from the dozer’s final drives to protect them from premature failure, and the mine required a more effective magnetic technology. If the service extension could be achieved, the cost savings would be significant in terms of reducing transport (float hire), unscheduled downtime, equipment replacement, and maintenance.

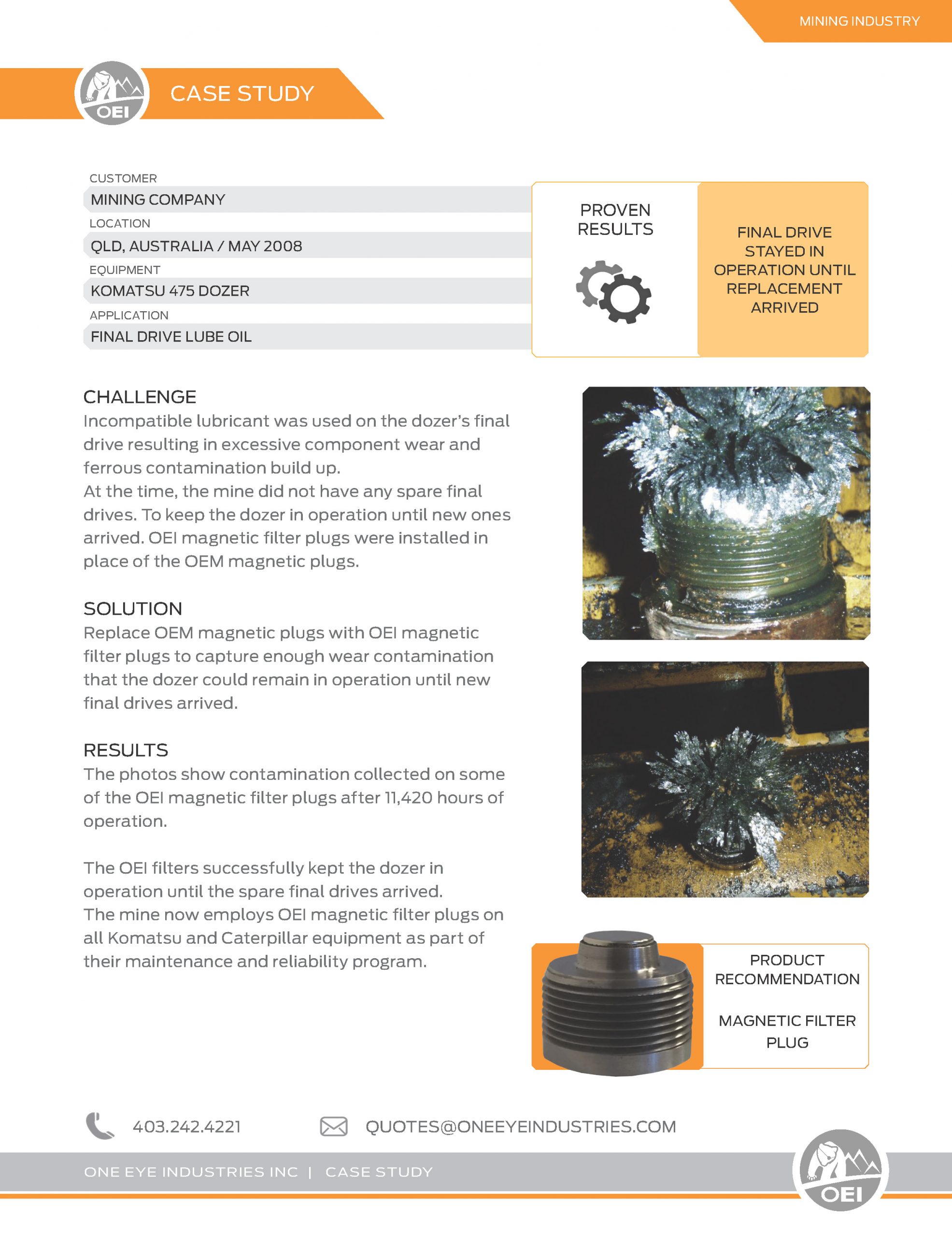

Komatsu 475 Dozers Final Drive Lube Oil

The Final Drives were fitted with One Eye magnetic plugs as they did not have spares and they needed the Dozer to keep going until the spares arrived. This is the results after 11,420 hrs.

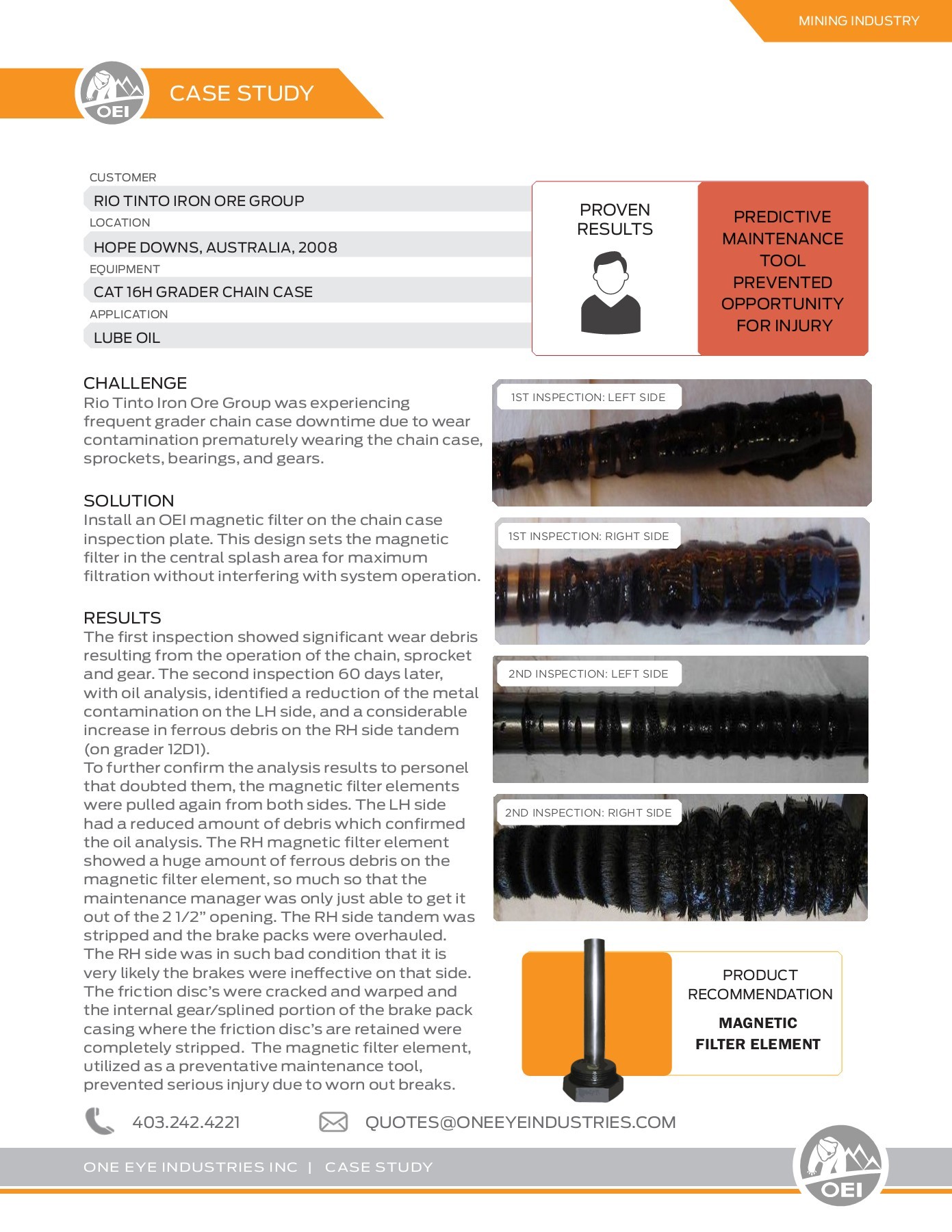

Preventing Break Failure on a 16H Grader

Rio Tinto Iron Ore Group was experiencing frequent grader chain case downtime due to wear contamination prematurely wearing the chain case, sprockets, bearings, and gears.

Yanacocha Cat 24 H Gold Mine Grader

Excessive amount of metal contamination in the lube oil is the result of wear from the chain, sprocket and gears in a reservoir that has no filtration. This lube oil also acts as a coolant for the wet brakes causing premature brake disk and bearing failure.

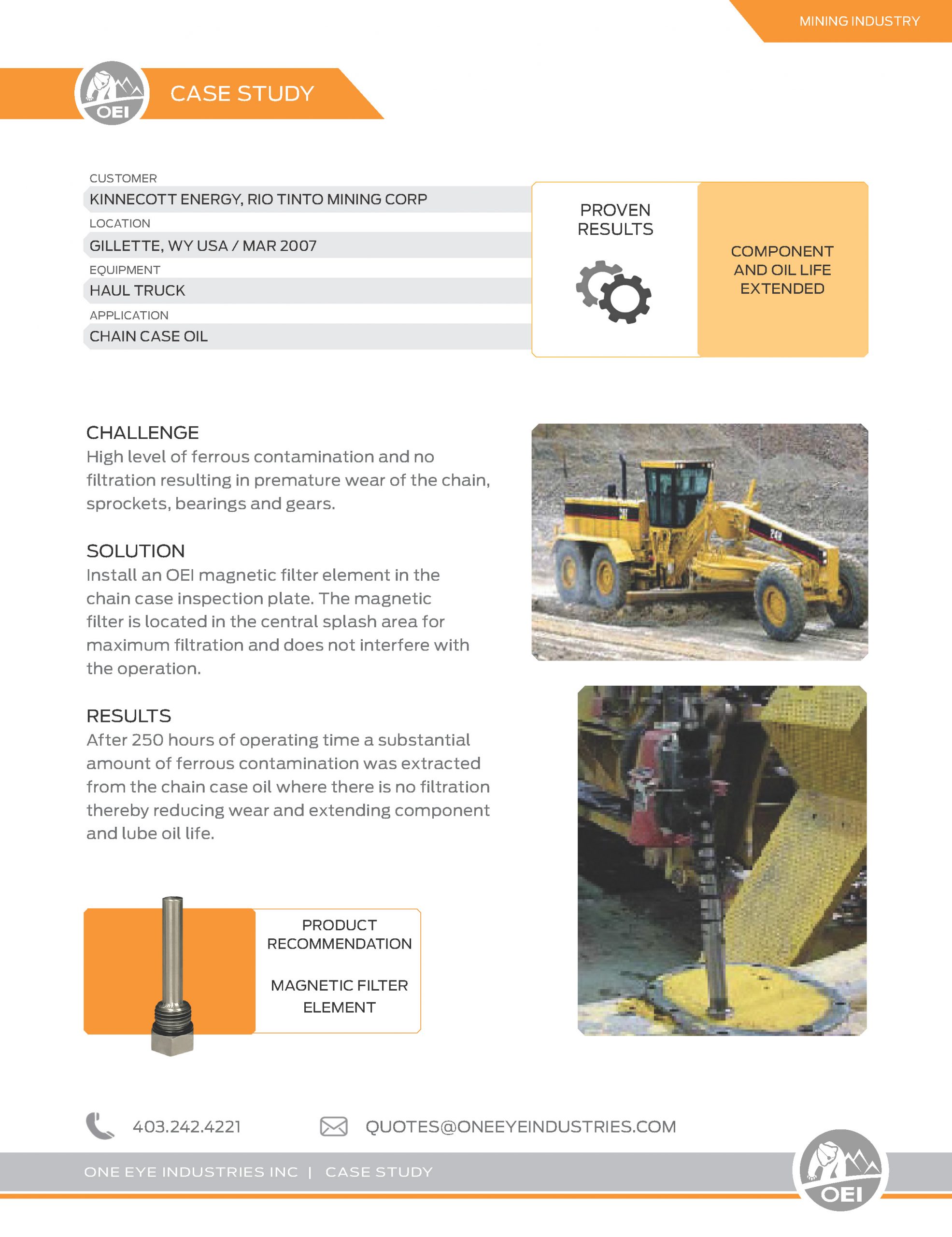

Rio Tinto Chain Case Oil 24H Grader

Bob Anderson reported that after 250 hours of operating time a substantial amount of ferrous contamination was extracted from the chain case oil where there is no filtration thereby reducing wear and extending component and lube oil life.

Haul Truck Front Wheel Hub Roller Bearings

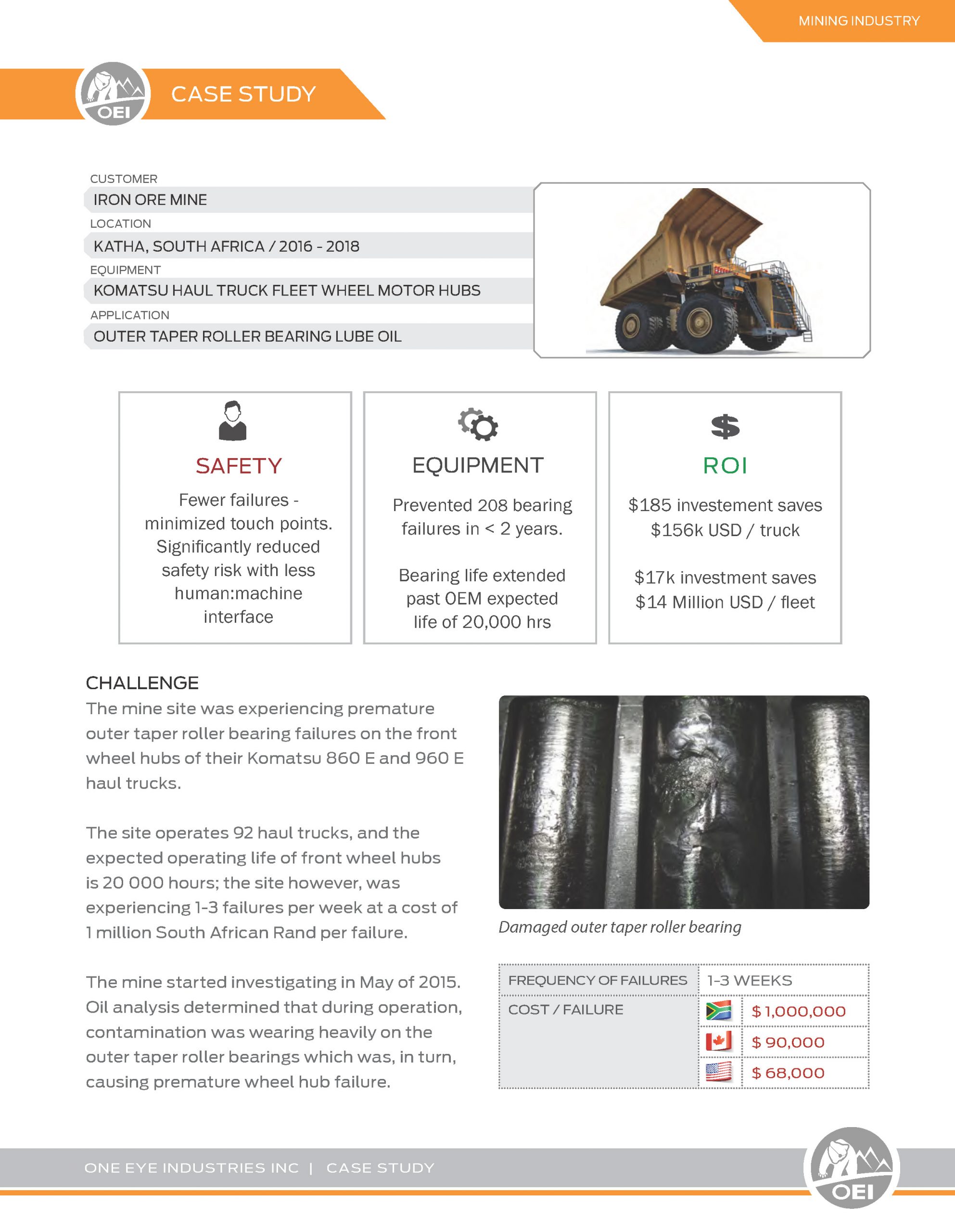

The mine site was experiencing premature outer taper roller bearing failures on the front wheel hubs of their Komatsu 860 E and 960 E haul trucks.

The site operates 92 haul trucks, and the expected operating life of front wheel hubs is 20 000 hours; the site however, was experiencing 1-3 failures per week at a cost of 1 million South African Rand per failure.

The mine started investigating in May of 2015. Oil analysis determined that during operation, contamination was wearing heavily on the outer taper roller bearings which was, in turn, causing premature wheel hub failure.

Predictive Maintenance on a 930E Haul Truck Wheel Motor

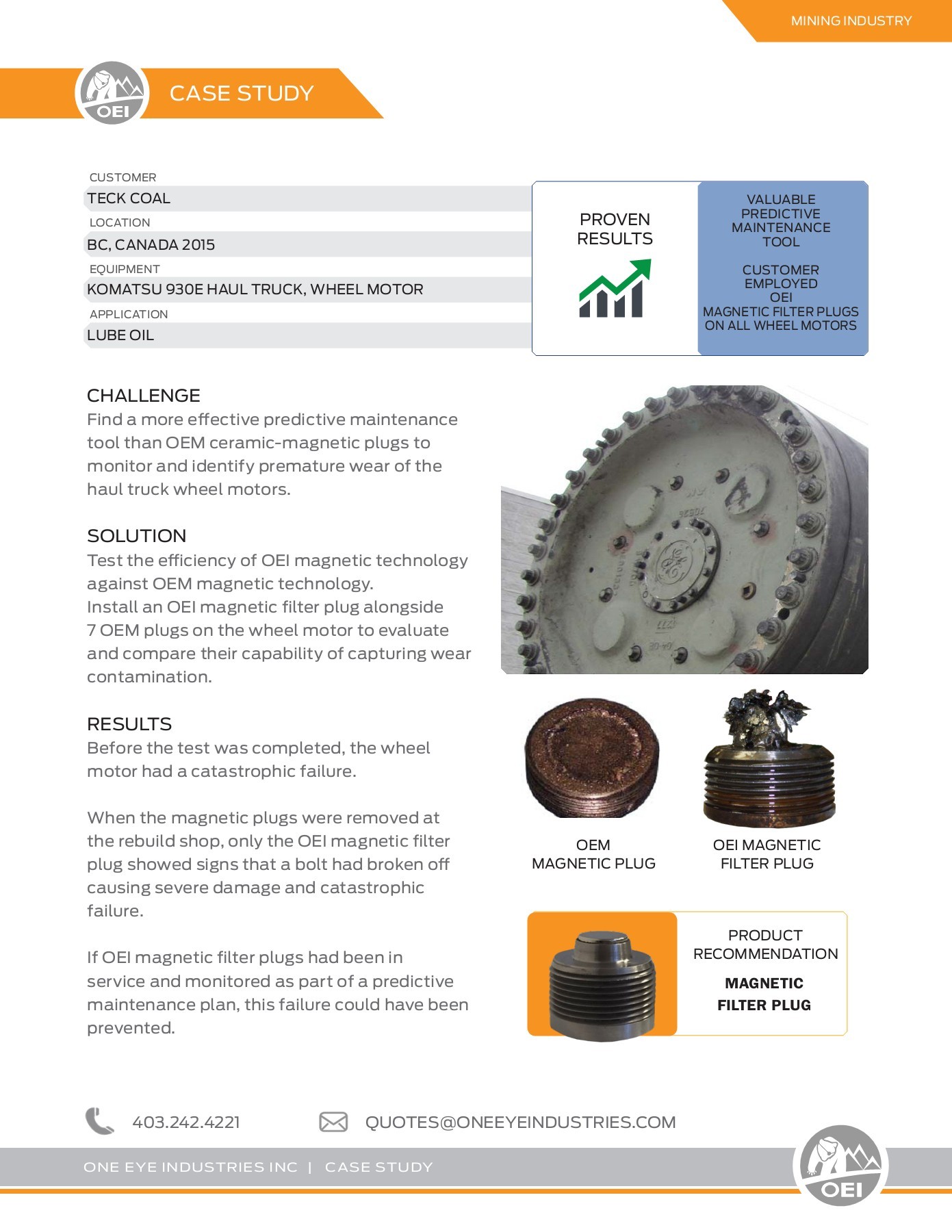

The challenge was to find a more effective predictive maintenance tool than OEM ceramic-magnetic plugs to monitor and identify premature wear of the haul truck wheel motors.

GE Wheel Motors Komatsu 830E

High levels of ferrous metal contamination causing premature wear. Perry Simunek’s implementation of the OEI magnetic filters has located another area in need of improvement.

Iron Ore Komatsu 830E Wheel Motor GE 787

OEI’s new Filler Cap design allows the fluid level to be checked without removing the filler cap. An oil sample can be taken by inserting the hose into the dip stick pipe. The pipe is designed to only allow the sample hose to a predetermined depth so sampling will be consistent.

Iron Ore Komatsu 830E Wheel Motor Lube Oil

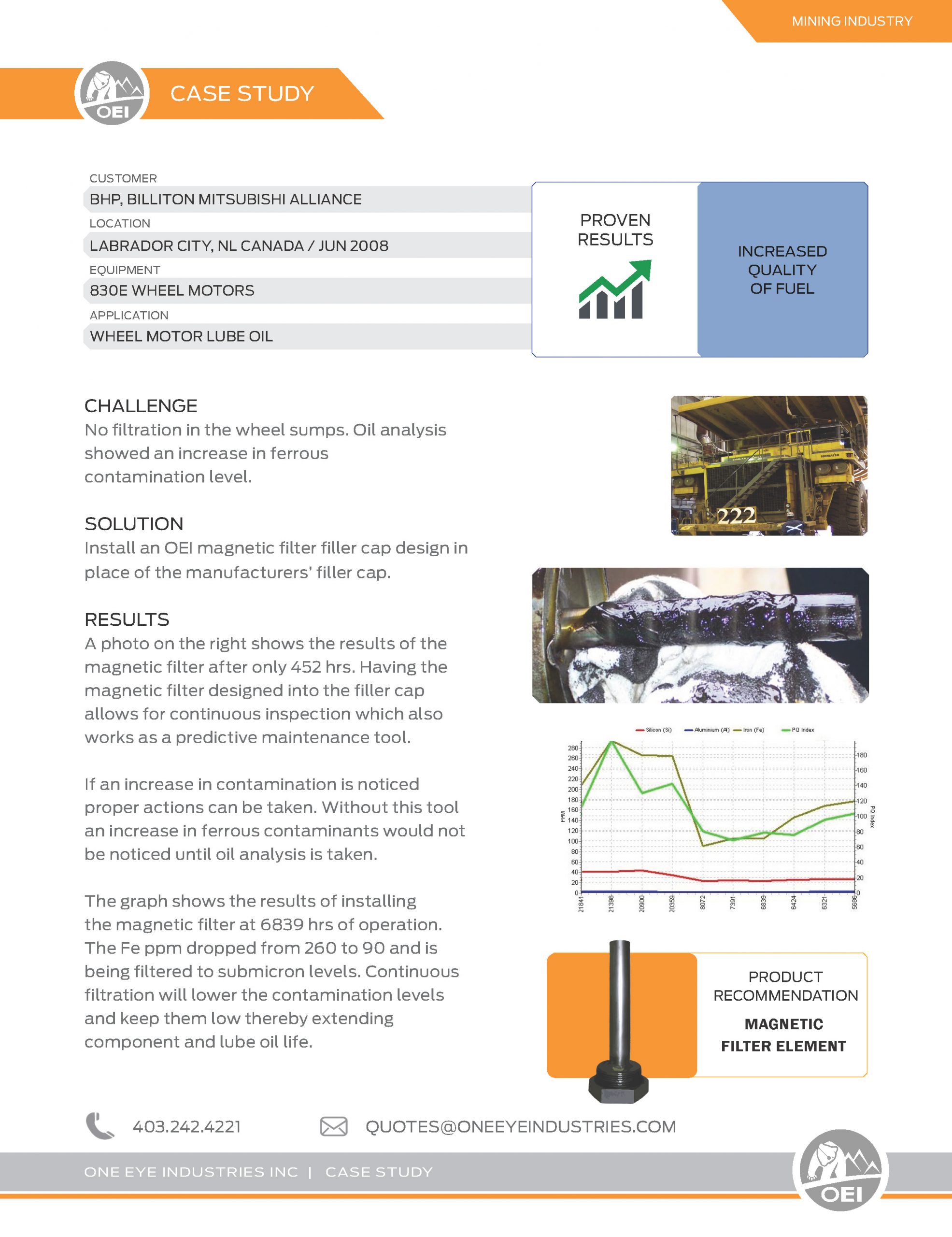

No Filtration in the wheel sumps. Oil Analysis shows an increase in ferrous contamination level.

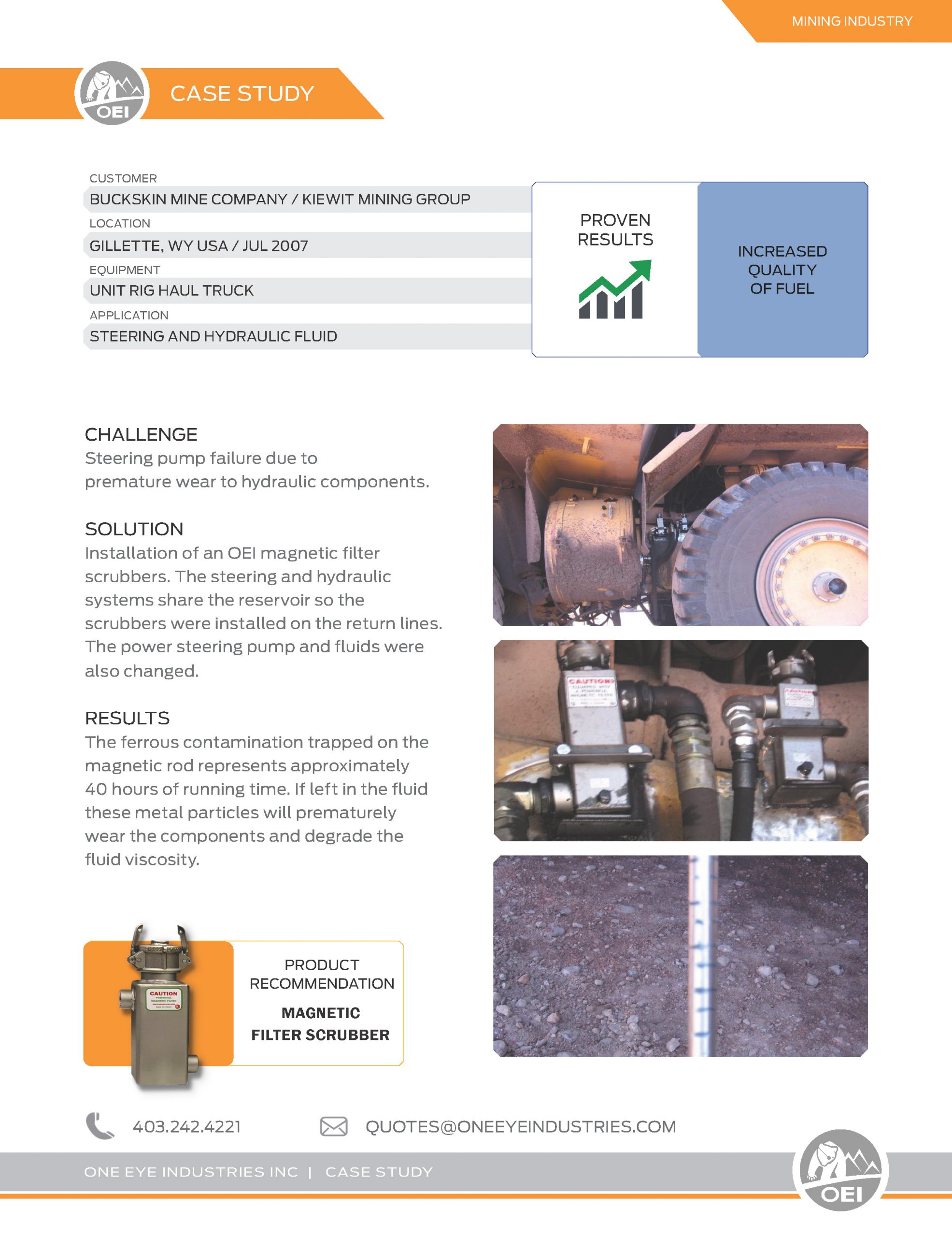

Kiewit Unit Rig Haul Truck Steering Fluid

The ferrous metal trapped on the magnetic rod represents approximately 40 hours of running time. If left in the fluid these metal particles will prematurely wear the components and degrade the fluid viscosity. The OEI magnetic filter is easily cleaned and the trapped contamination can be analyzed for component wear identification allowing predictive maintenance planning.

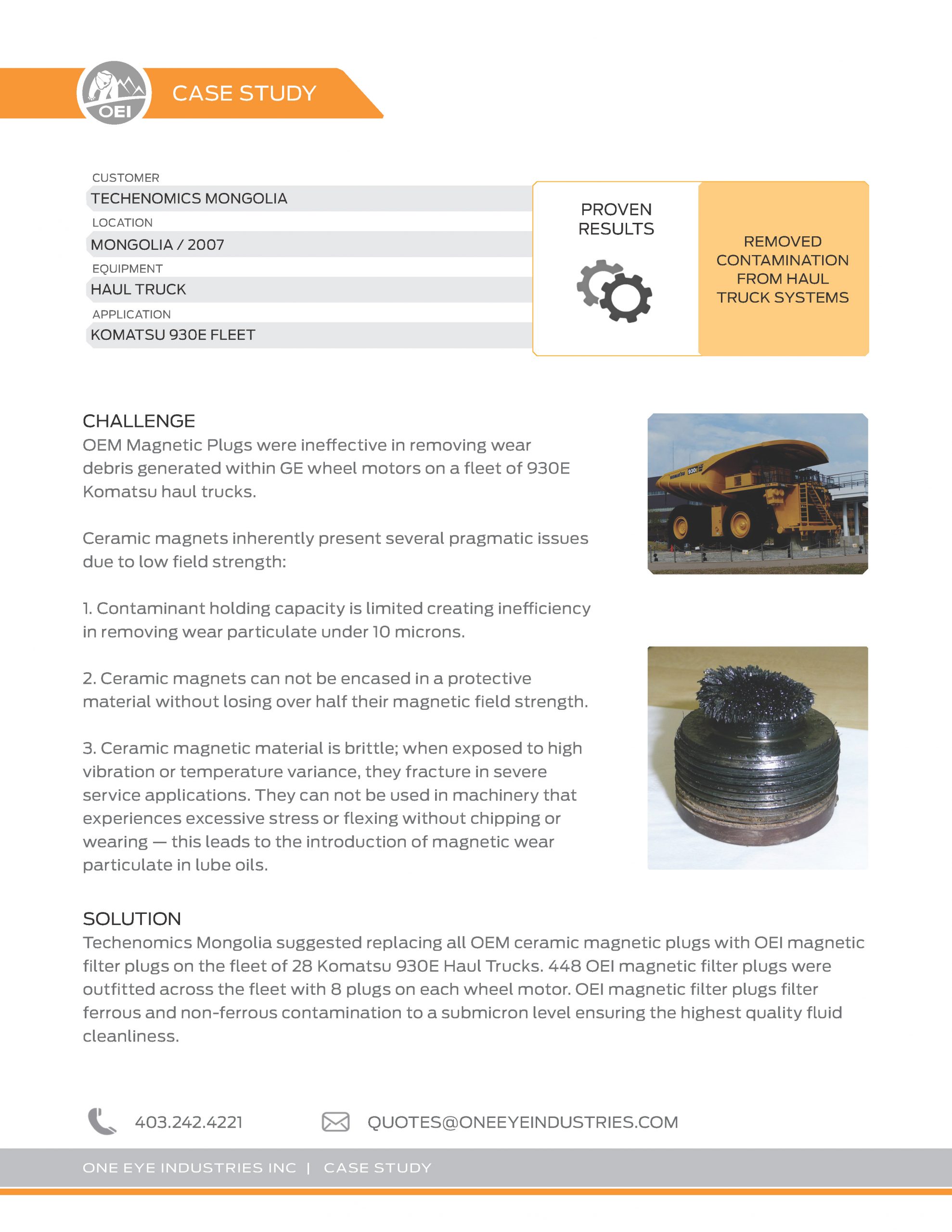

Komatsu 930E Fleet Wheel Motor

Techenomics Mongolia suggested replacing all OEM ceramic magnetic plugs with OEI Magnetic Filter Plugs on the fleet of 28 Komatsu 930E Haul Trucks. 448 OEI Magnetic Filter Plugs were outfitted across the fleet with 8 plugs on each wheel motor. OEI Magnetic Filter Plugs filter ferrous and non-ferrous contamination to a submicron level ensuring the highest quality fluid cleanliness.

Mainland Sand and Gravel Cat Haul Truck Gearbox

The planetary gearboxes in the wheel motors of their CAT Haul Trucks were failing prematurely due to excessive contamination ISO 23/21 (the majority Calcium dust) which was entering into the system through the poor quality air breathers. Traditional kidney loop filtration was unable to remove these particles as they were under 10 microns to sub-micron in size.

Rio Tinto Komatsu 830E Hope Downs

The trends for Fe show a significant drop after the installation of the OEI Magnetic Filter from 105ppm to 20ppm and 85ppm to 20ppm. As of the last sample taken, both sumps are now at 5ppm Fe. After 1748hrs the magnetic filters were inspected and the following was found.

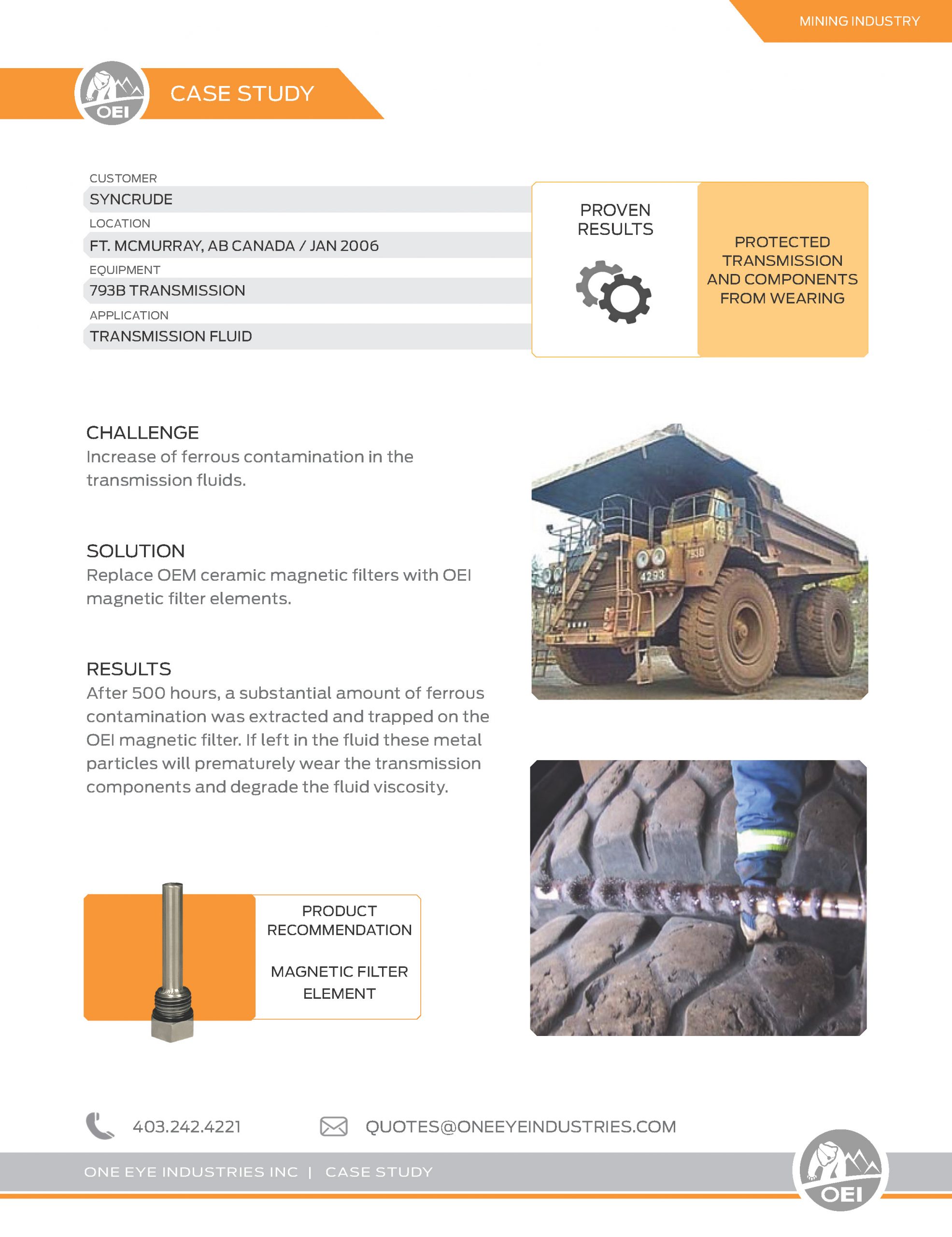

Syncrude 793B Transmission Fluid

After 500 hours, a substantial amount of Ferrous Metal was extracted and trapped on the OEI magnetic filter. If left in the fluid these metal particles will prematurely wear the transmission components and degrade the fluid viscosity.

Shovels and Draglines

Dragline Gearbox Testimonials

The challenge was to lower the ferrous contamination levels in dragline #5 gearboxes, and improve ISO fluid cleanliness levels.

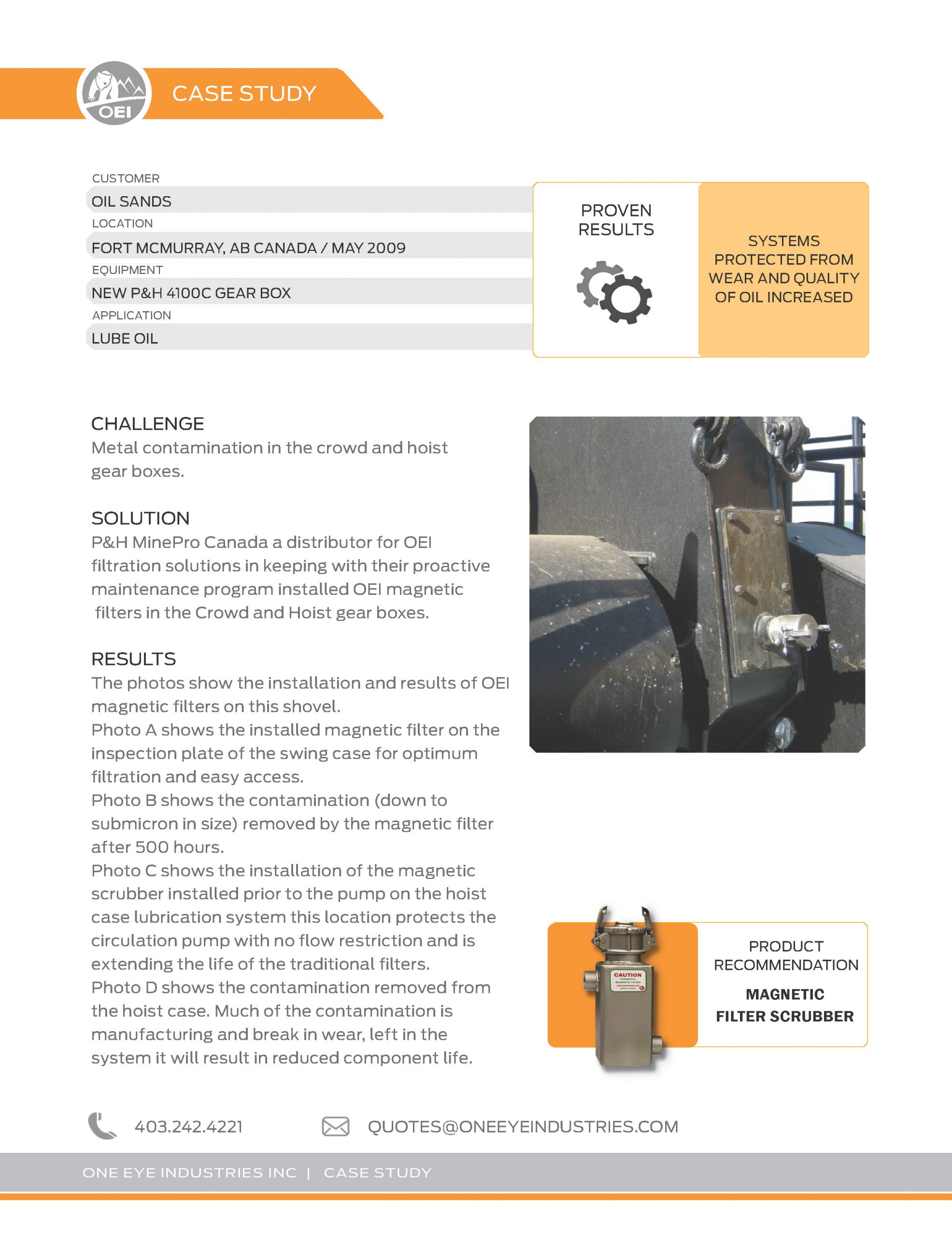

Oil Sands P&H 4100C Gear Box Lube Oil

P&H MinePro Canada a distributor for OEI filtration solutions in keeping with their proactive maintenance program installed OEI magnetic filters in the Crowd and Hoist gear boxes.

Rio Tinto P&H XP2800 Crowd Gearbox Lube Oil

No filtration for the gear oil in the Crowd gear box and increasing levels of ferrous metal contamination are prematurely wearing the components and reducing the lube oil life. Perry Simunek (Maintenance Engineer) was challenged with the task of improving the ISO cleanliness levels on Rio Tinto’s Equipment.

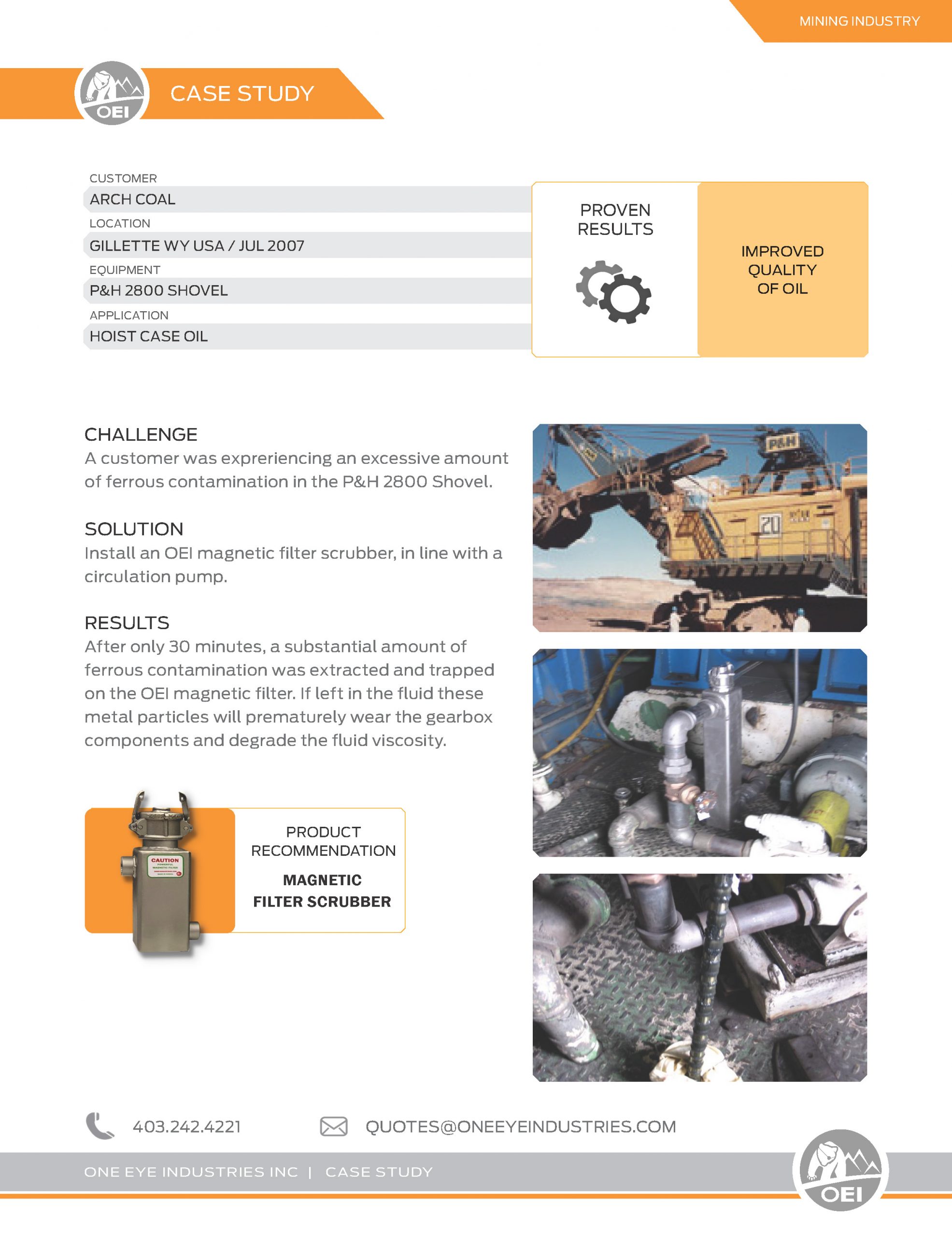

Arch Coal P&H 2800 Shovel Hoist Case

After only 30 minutes, a substantial amount of Ferrous Metal was extracted and trapped on the OEI magnetic filter. If left in the fluid these metal particles will prematurely wear the gearbox components and degrade the fluid viscosity.

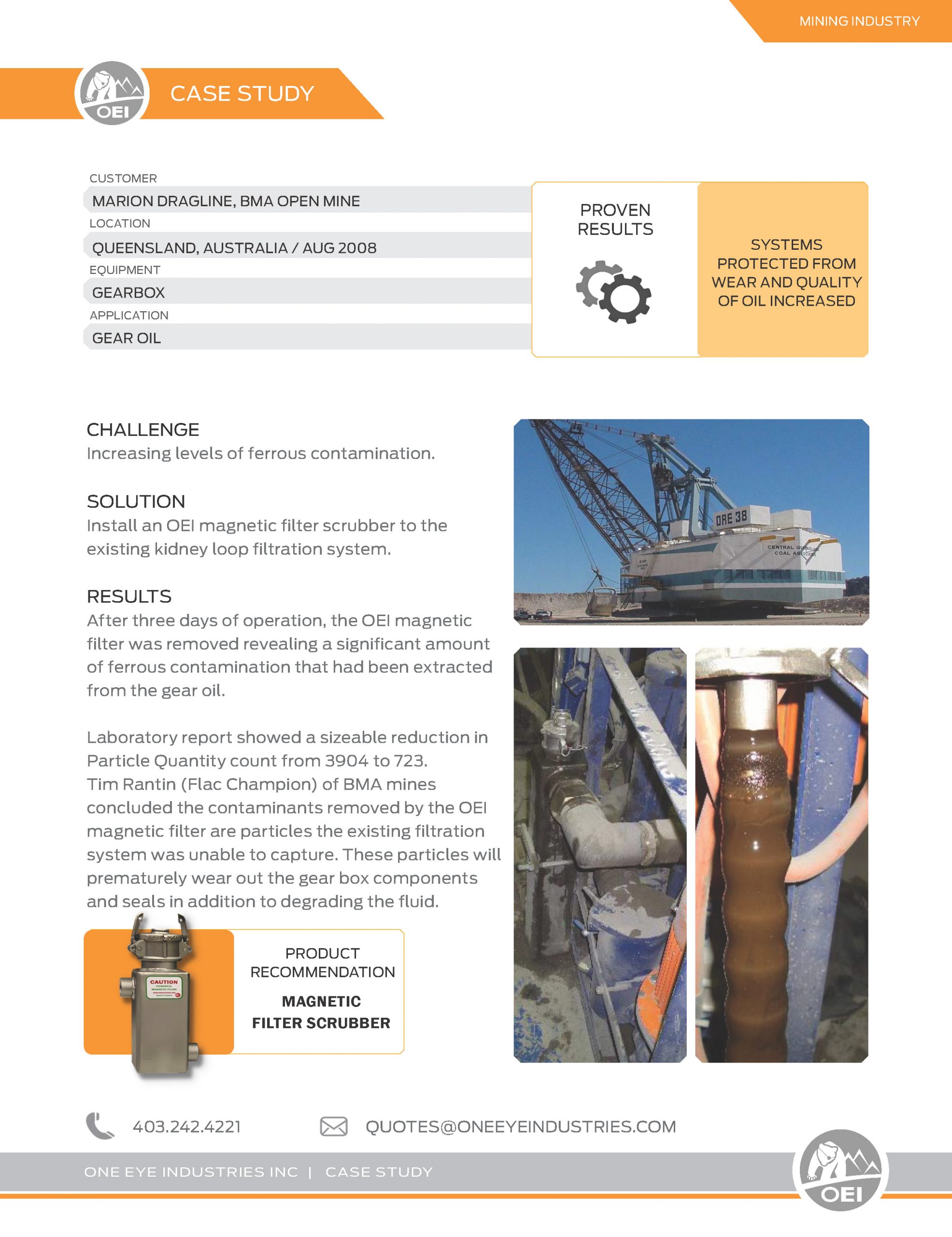

BMA Open Cut Coal Mine Marion Dragline

After three days of operation, the OEI magnetic filter was removed revealing a significant amount of ferrous contamination that had been extracted from the gear oil. Laboratory report showed a sizeable reduction in Particle Quantity count from 3904 to 723.

Copper Mine PH2800 Crowd Hoist Swing Case

Keeping with their proactive maintenance program, installation of OEI’s magnetic filters on the Crowd, Hoist and Swing Case kidney loop systems were mandated.

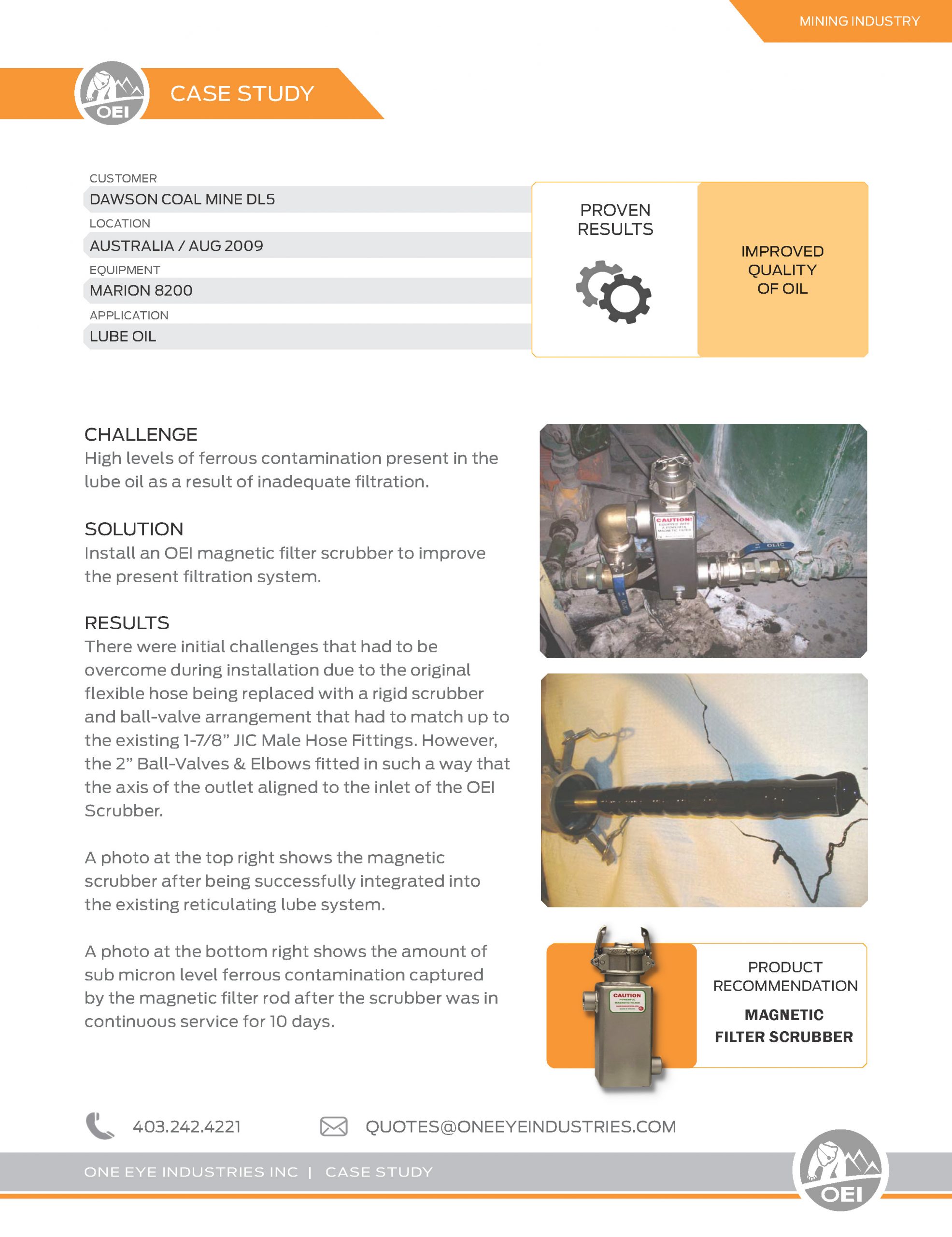

Dawson Coal Mine Marion Swing Case Gear Lube

There were initial challenges that had to be overcome during installation due to the original flexible hose being replaced with a rigid scrubber and ball-valve arrangement that had to match up to the existing 1-7/8” JIC Male Hose Fittings. However, the 2” Ball-Valves & Elbows fitted in such a way that the axis of the outlet aligned to the inlet of the OEI Scrubber.

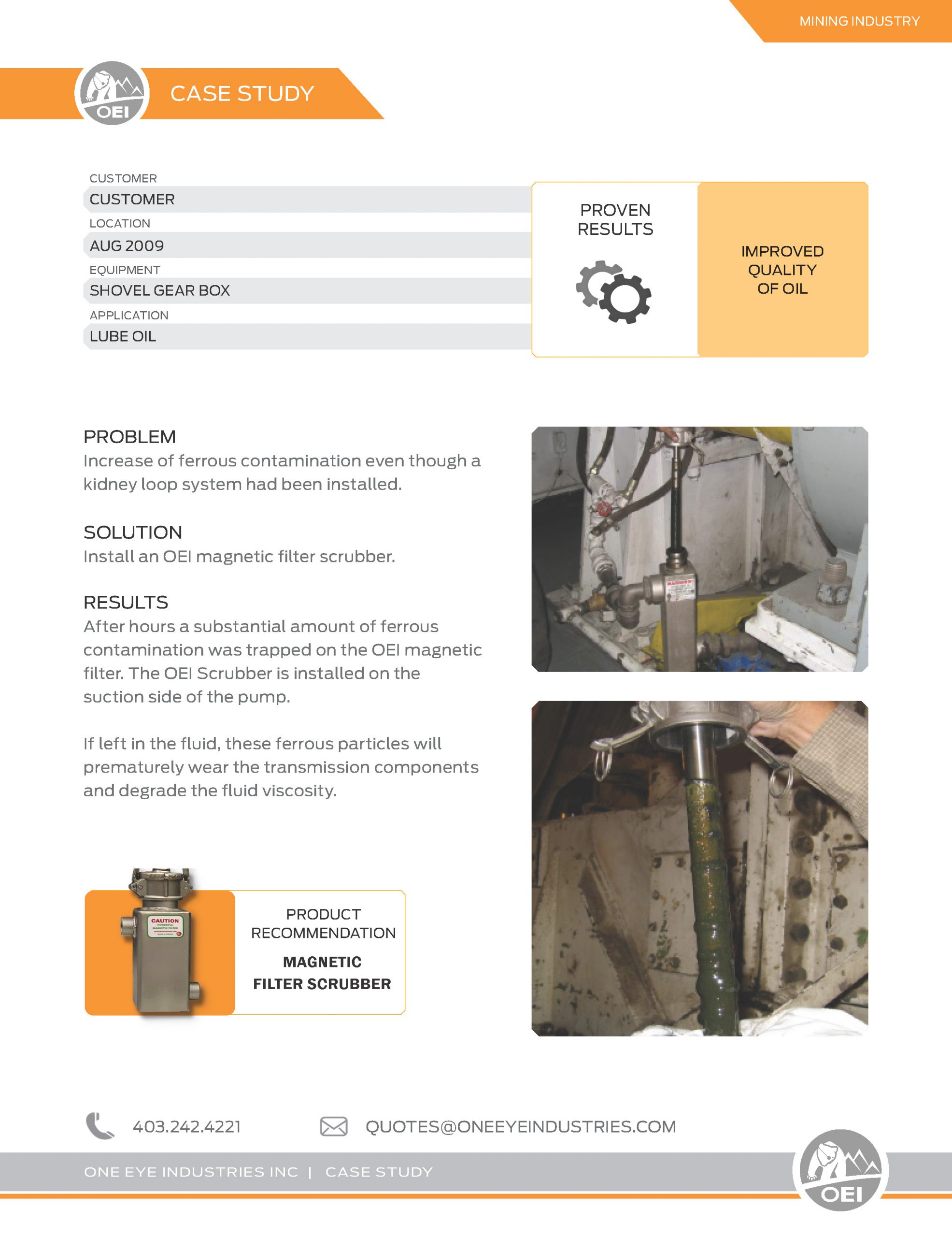

Shovel Gearbox

After hours a substantial amount of ferrous metal contamination was trapped on the OEI magnetic filter. The OEI Scrubber is installed on the suction side of the pump. If left in the fluid, these ferrous metal particles will prematurely wear the transmission components and degrade the fluid viscosity.

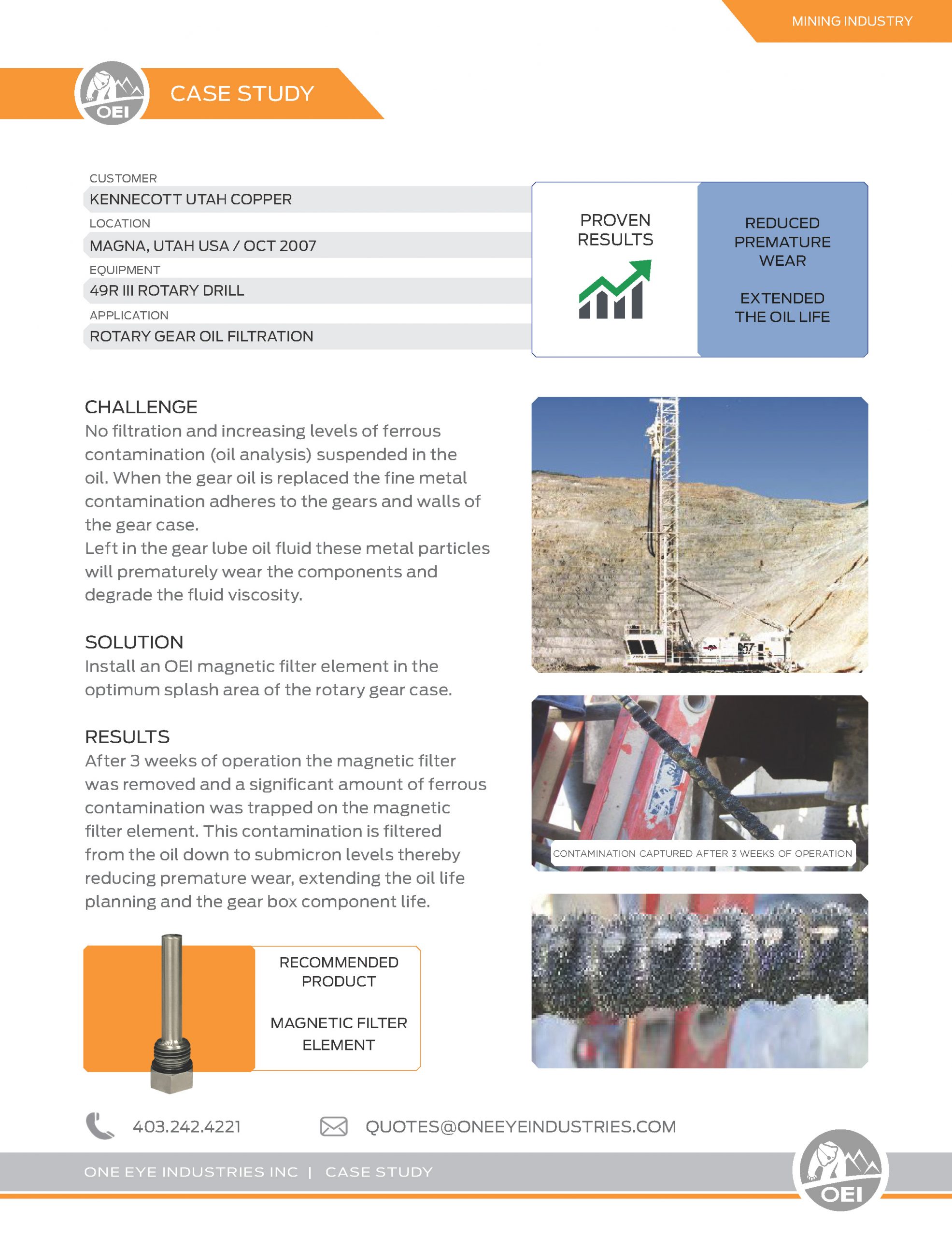

Kennecott Copper Bucyrus 49R Rotary Gear

No filtration and increasing levels of ferrous contamination (oil analysis) suspended in the oil. When the gear oil is replaced the fine metal contamination adheres to the gears and walls of the gear case. Left in the gear lube oil fluid these metal particles will prematurely wear the components and degrade the fluid viscosity.

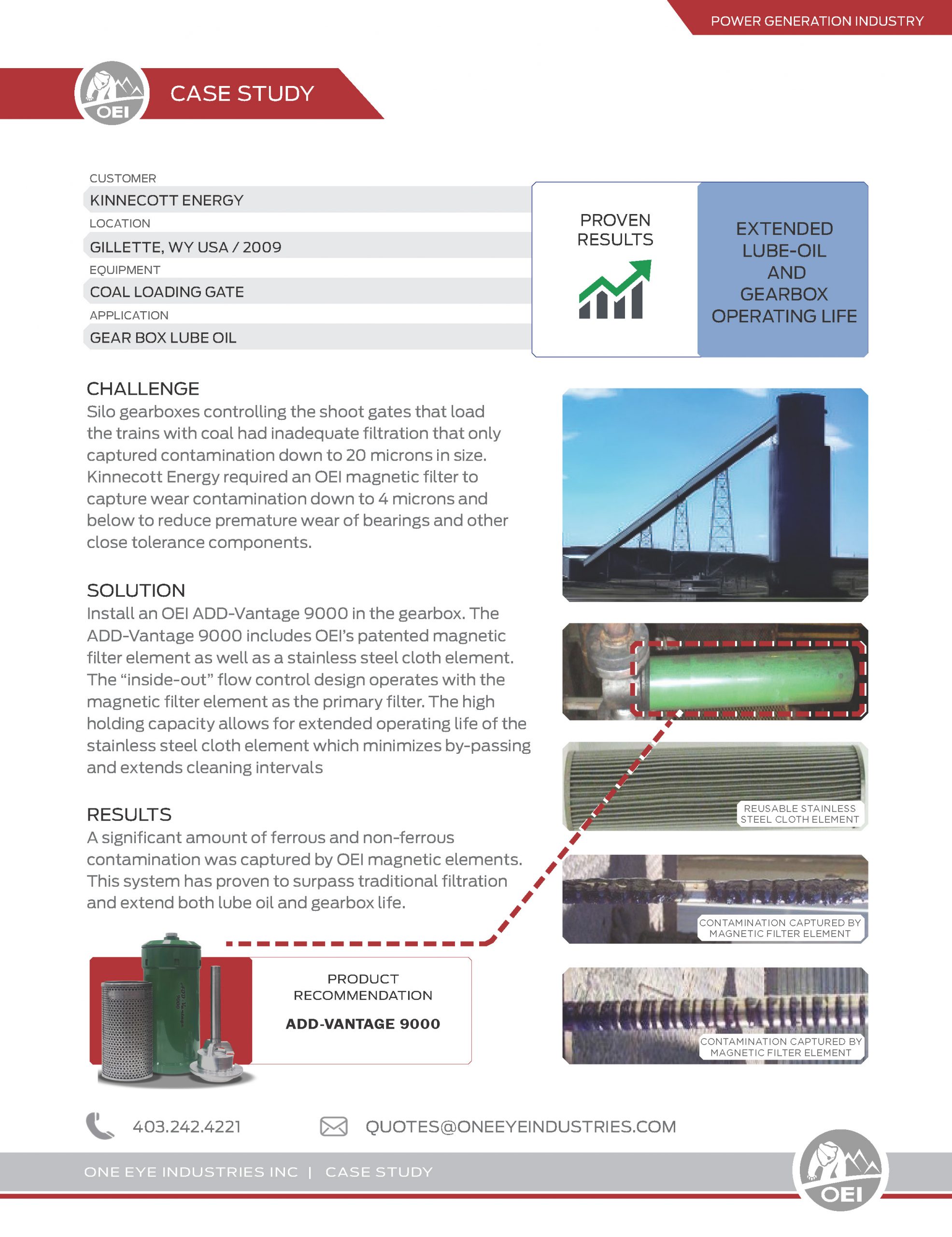

Kinnecott Energy Coal Loading Gate Gearbox

Silo gearboxes controlling the shoot gates that load the trains with coal had inadequate filtration that only captured contamination down to 20 microns in size. Kinnecott Energy required an OEI magnetic filter to capture wear contamination down to 4 microns and below to reduce premature wear of bearings and other close tolerance components.

Hydaulics

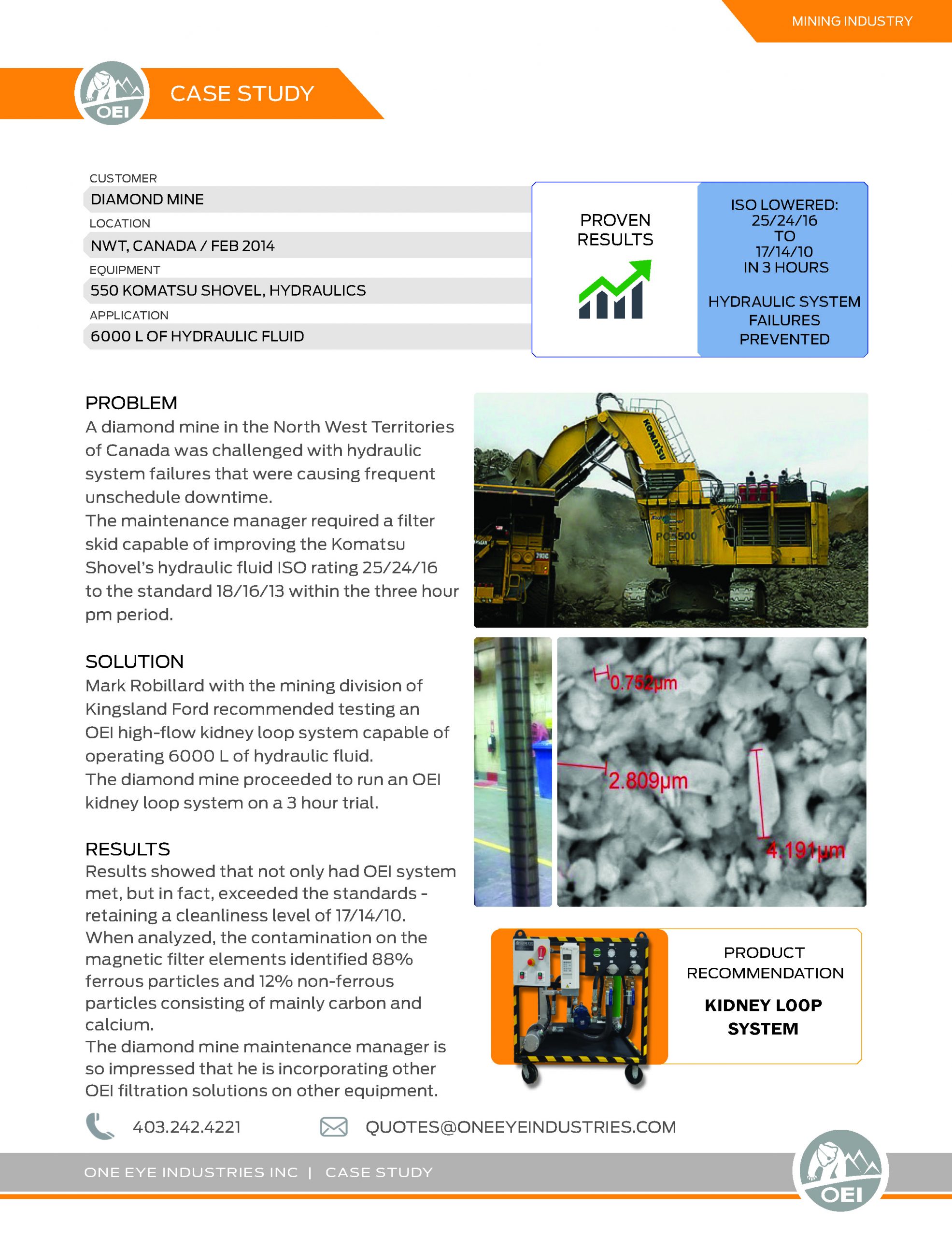

Exceeding Hydraulic Fluid ISO Standard Within a 3 Hour PM Period

A diamond mine in the North West Territories of Canada was challenged with hydraulic system failures that were causing frequent unschedule downtime. The maintenance manager required a filter skid capable of improving the Komatsu Shovel’s hydraulic fluid ISO rating 25/24/16 to the standard 18/16/13 within the three hour pm period.

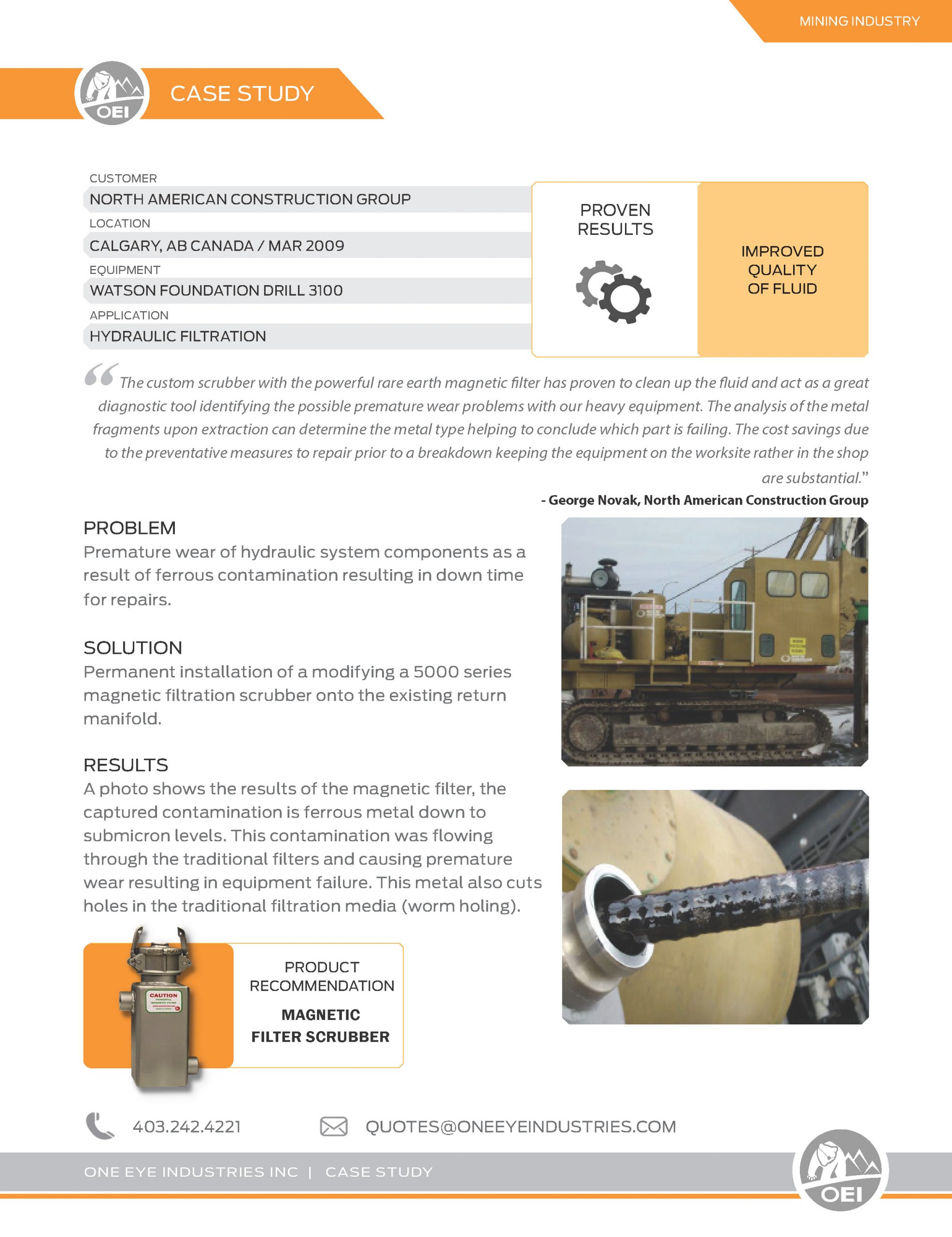

North American Construction Watson Foundation Drill Hydraulic Filtration

The custom scrubber with the powerful rare earth magnetic filter has proven to clean up the fluid and act as a great diagnostic tool identifying the possible premature wear problems with our heavy equipment. The analysis of the metal fragments upon extraction can determine the metal type helping to conclude which part is failing. The cost savings due to the preventative measures to repair prior to a breakdown keeping the equipment on the worksite rather in the shop are substantial

LaFarge Clemro 500 New Gravel Crusher

Ferrous Contamination during start up. When purchasing a new gravel crusher, maximizing the operational longevity of the equipment is very important. To protect the hydraulic system from premature failure is a very important aspect with the operational management. Ferrous metal under 10 microns in size is the most damaging contaminant in a closed hydraulic system and traditional filtration is unable to remove it.

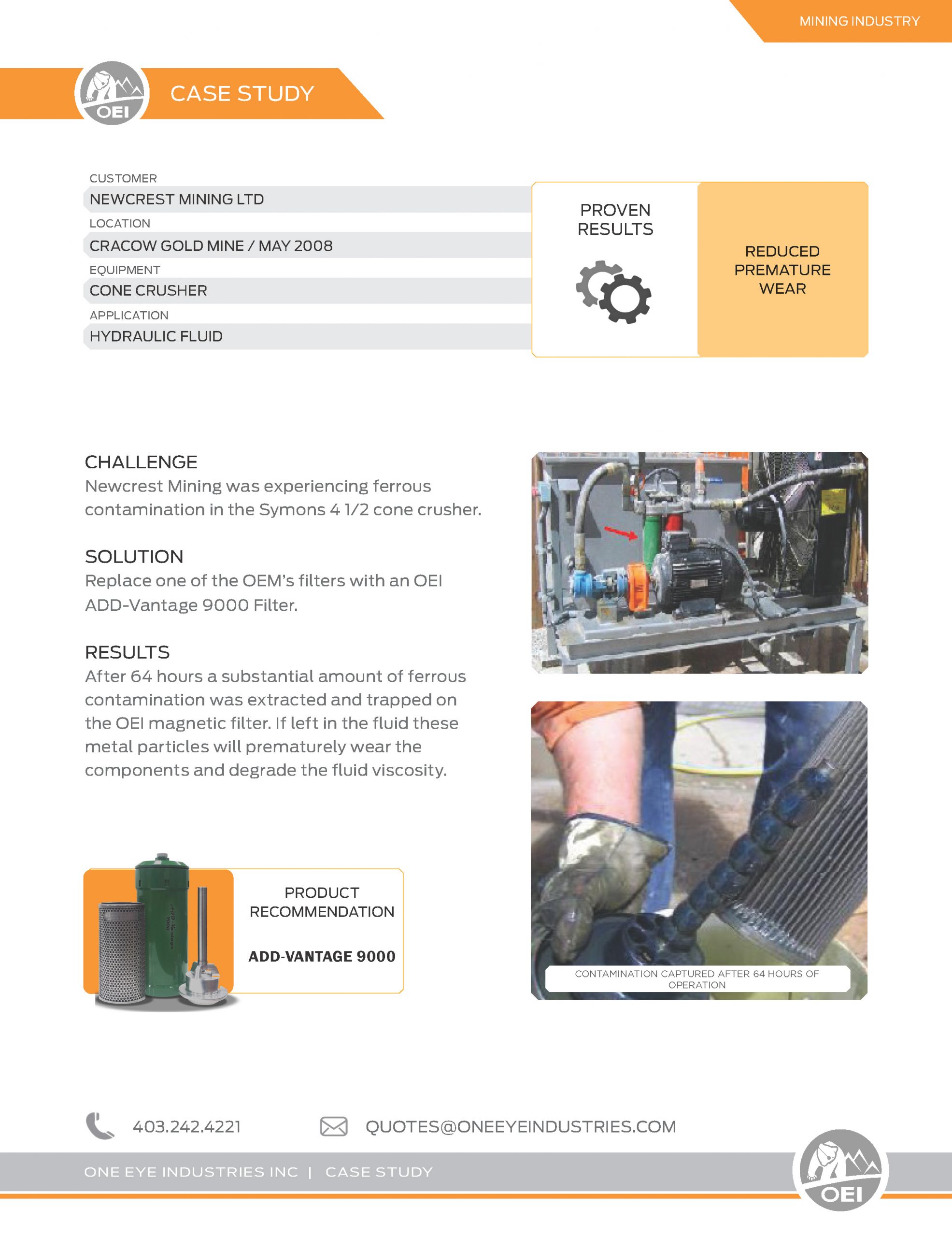

Newcrest Mining Cone Crusher

Newcrest’s view is that without the One Eye filter a proportion of this material would have found its way back to the bearings, gears and lubrication pump. This could have lead to premature failures and costly unplanned maintenance. As part of the continuous improvement program at this site we have identified other pieces of critical plant equipment that will benefit from the advantages of magnetic filters.

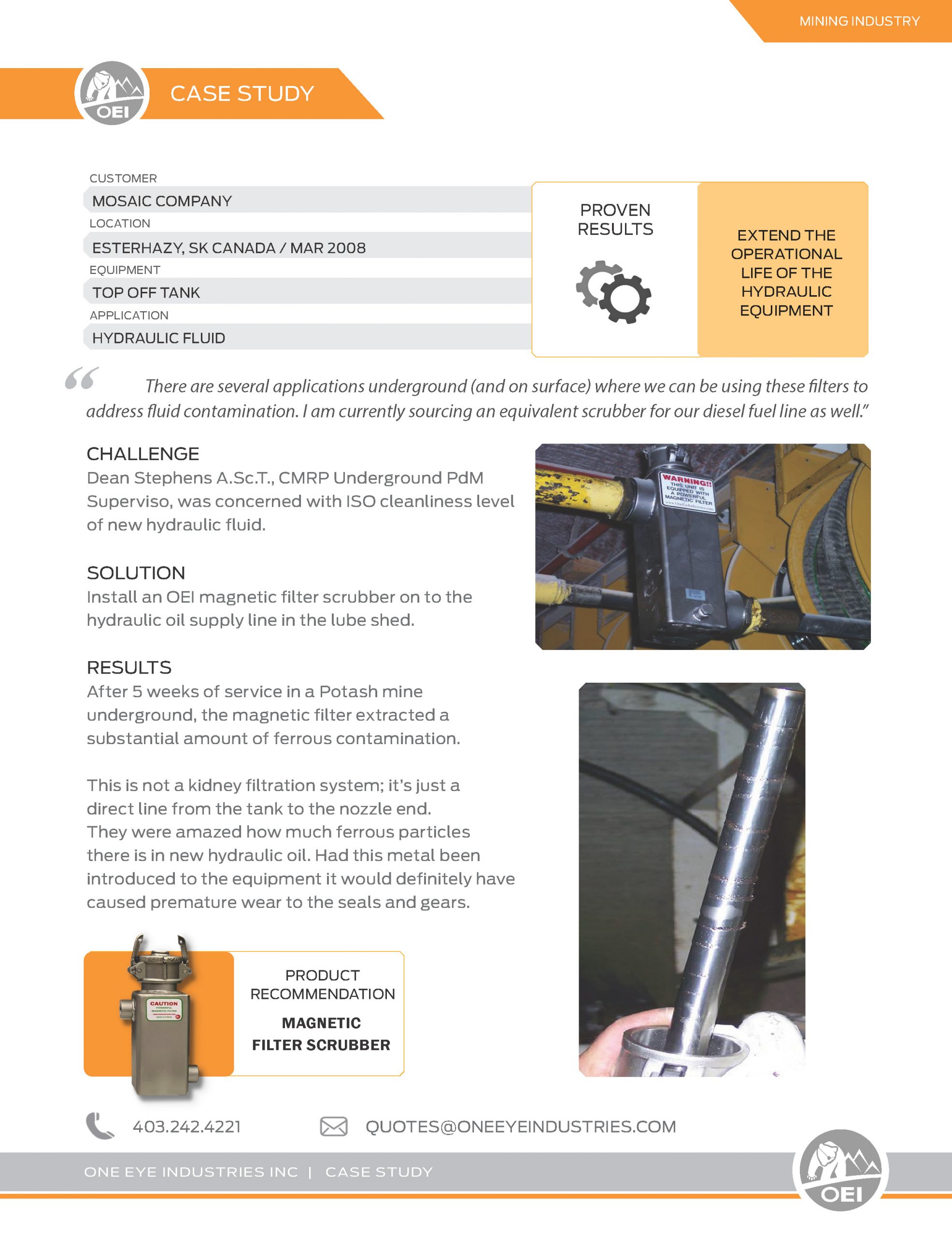

Mosaic Hydraulic Top Off Tank

After 5 weeks of service in a Potash mine underground, the magnetic filter extracted a substantial amount of ferrous metal. This is not a kidney filtration system; it’s just a direct line from the tank to the nozzle end. They were amazed how much ferrous metal there is in new hydraulic oil. Had this metal been introduced to our equipment it would definitely have caused premature wear to the seals and gears.

Plant Equipment

Dispensers

ColoWyo Mine Protecting Tier 3 and 4 Engines

Out of concern for the new tier 3 and 4 engine tolerances, Colowyo wanted to improve their diesel fuel engine cleanliness to minimize ianjector and pump wear.

Consol Energy Corp Diesel Fuel Dispensing

The challenge was to protect mining equipment from wear contamination under 4 microns that would damage close tolerance fuel system components; filter the diesel fuel coming out of the tanks, prior to dispensing.

IOCC High Flow Diesel Fuel Line Filtration

IIOC was concerned with their diesel fuel meeting higher-tier engine fuel cleanliness requirements. Existing fuel cleanliness aligned with North American fuel delivery standards, however, IOCC wanted to improve on the cleanliness in order to minimise on injector and pump component wear.

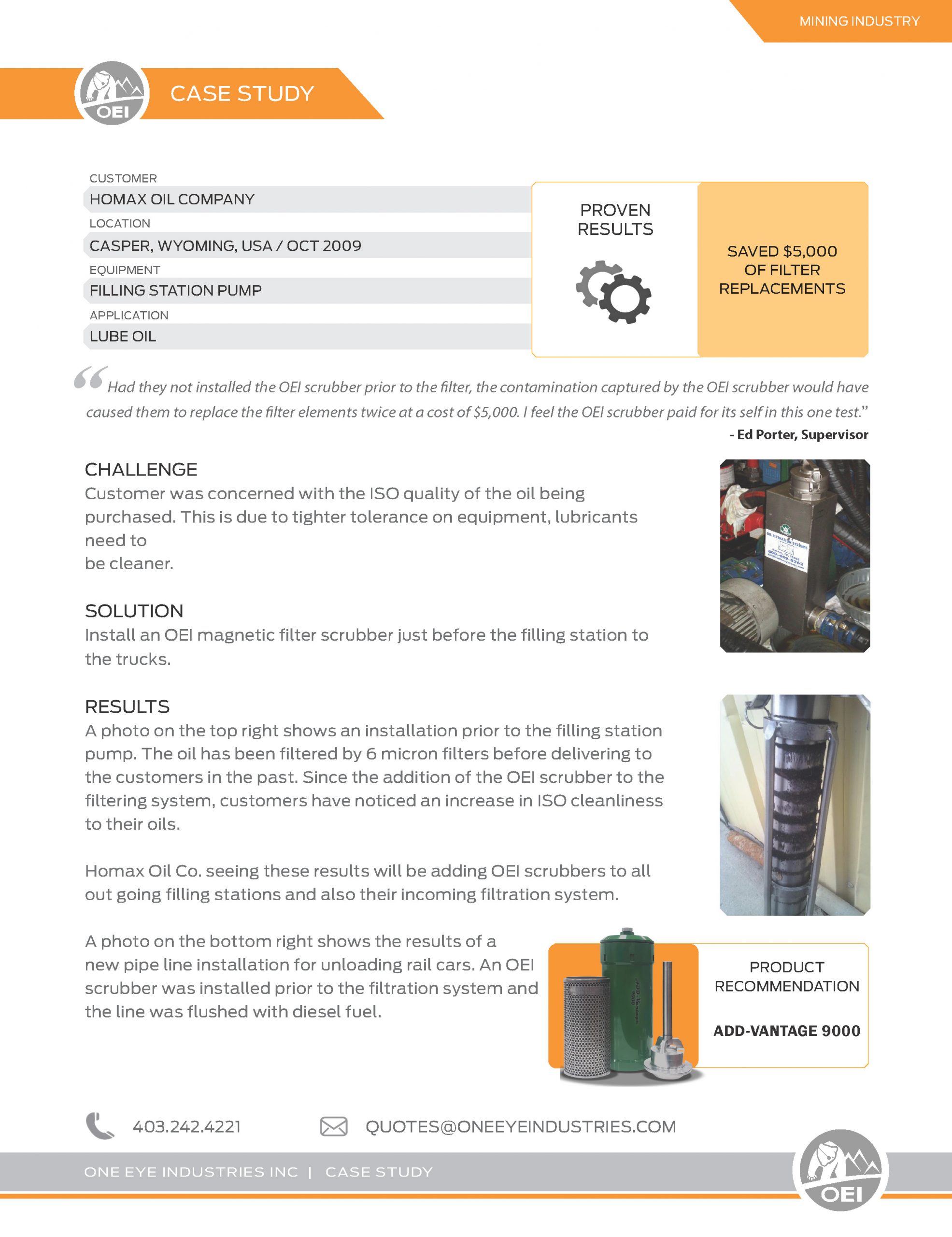

Homax Oil Lube Oil Dispensing

Customers concern with the ISO quality of the oil being purchased. This is due to tighter tolerance on equipment, lubricants need to be cleaner.

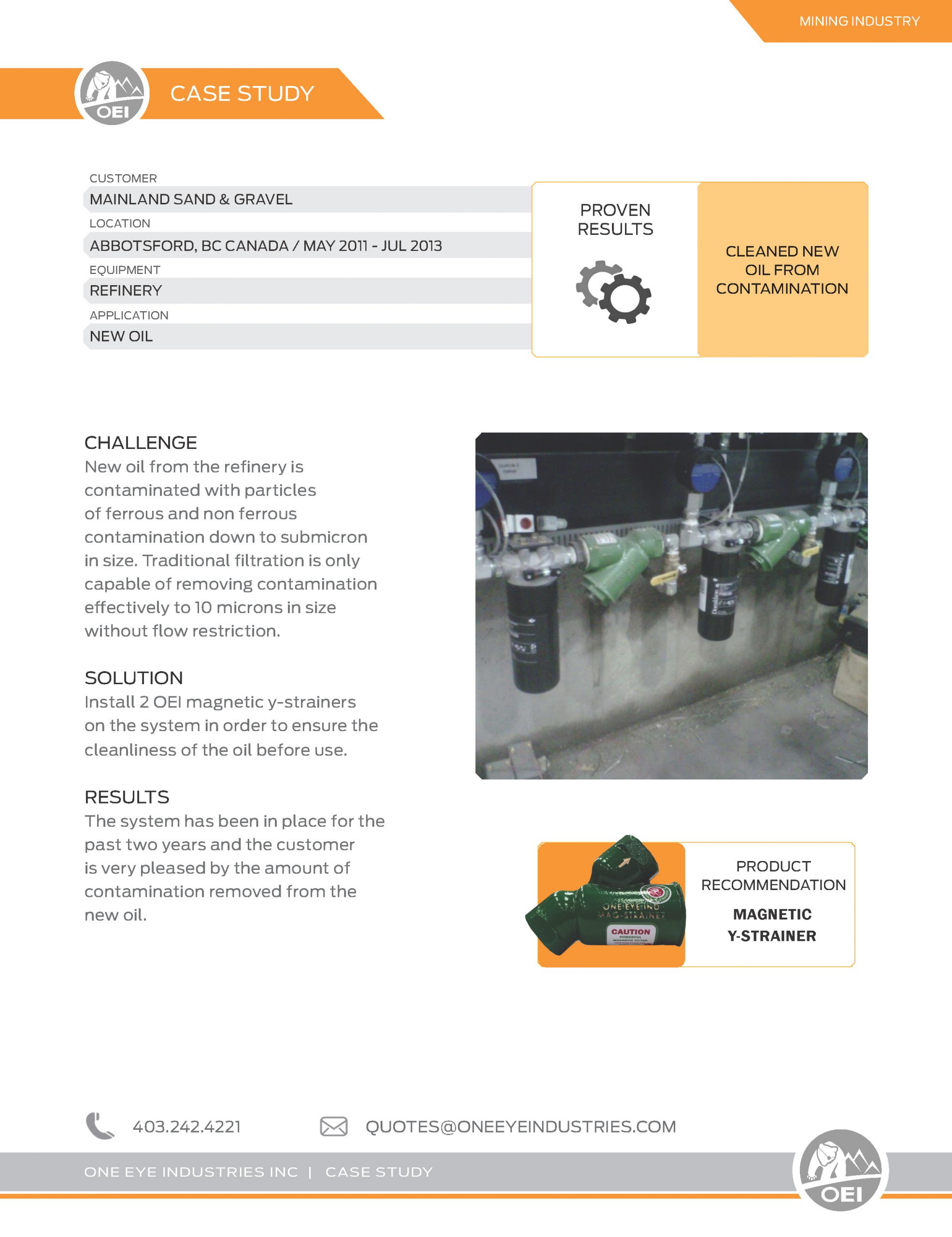

New Oil Filtraton Mainland Sand and Gravel

New oil from the refinery is contaminated with particles of ferrous and non ferrous contamination down to submicron in size. Traditional filtration is only capable of removing contamination effectively to 10 microns in size without flow restriction.

Gearboxes

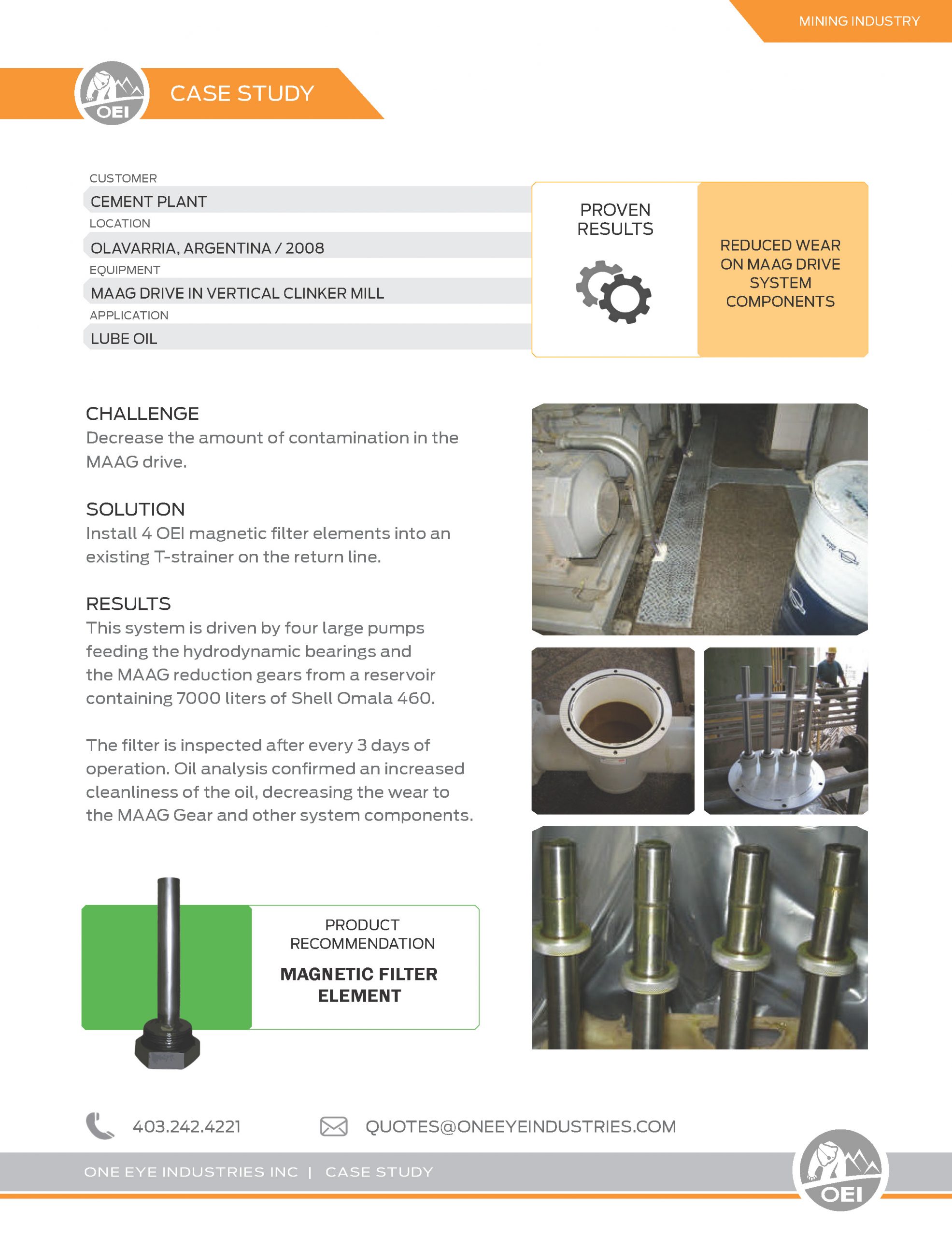

Argentina Cement Plant Maag Drive

The challenge was to decrease the amount pf contamination in the MAAG drive. As a solution, the customer installed 4 OEI magnetic filter elements into an existing T-strainer on the return line.

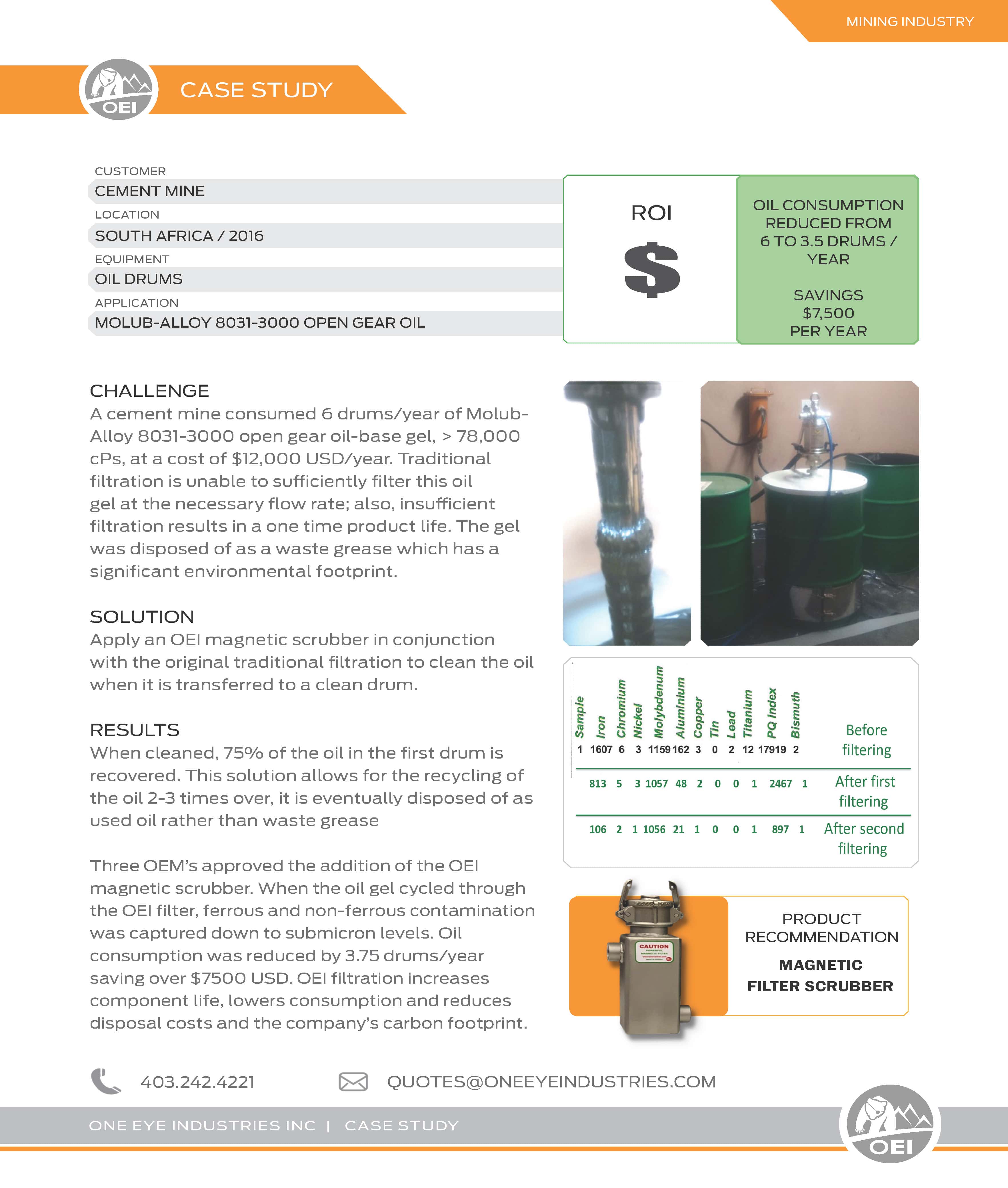

Filtering Heavy Lube Oil in Drums to Save Thousands

A cement mine consumed 6 drums/year of Molub-Alloy 8031-3000 open gear oil-base gel, > 78,000 cPs, at a cost of $12,000 USD/year. Traditional filtration is unable to sufficiently filter this oil gel at the necessary flow rate; also, insufficient filtration results in a one time product life. The gel was disposed of as a waste grease which has a significant environmental footprint. The challenge was to clean the oil when it is transferred to a clean drum.

Mount Polley Pebble Mill Lube Bearing Oil

Ferrous Metal Contamination. Geordie Tugnum of Bearing & Transmission a distributor for OEI recommended installing the OEI’s Magnetic Filter Y-Strainer.

Rio Tinto Copper North Parkes Conveyor Drive Gearbox

High level of ferrous metal contamination in the gear oil of the main underground haul out conveyor drive gearbox (capacity of 210 L).

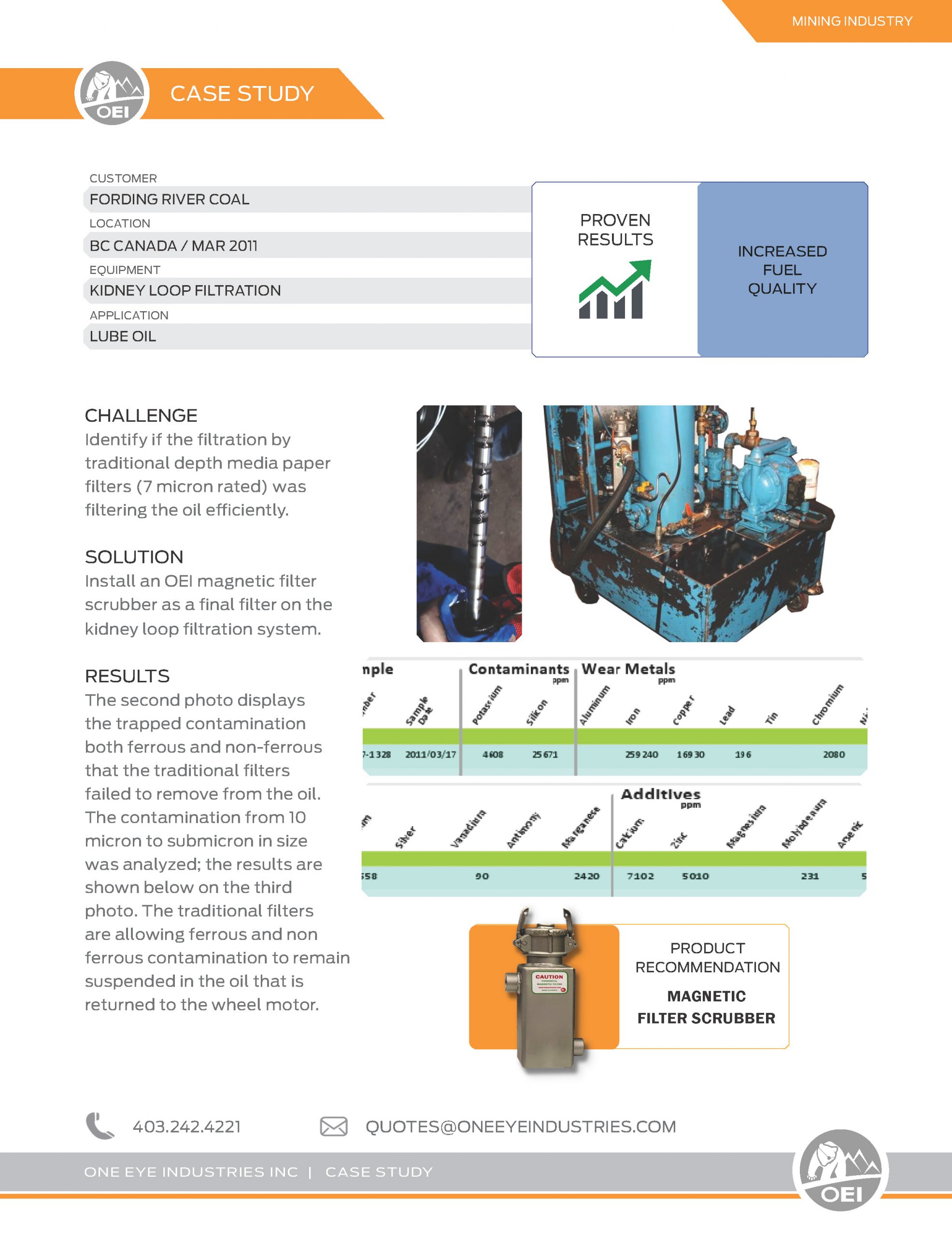

Fording River Kidney Loop

Identify if the filtration by traditional depth media paper filters (7 micron rated) was filtering the oil efficiently.

Interquisa PTA TA Dryer Lube Oil

Ferrous metal erosion contamination on the support roller lubrication system. The system does not have a filtration system for the lubrication oil. The contamination causes premature wear of the drums and plugs the oil spray lubrication.

Mount Polley Mining Pinion Lube Oil Regrind Ore Crusher

Geordie Tugnum a fluid specialist for Bearing & Transmission a distributor for OEI recommended replacing the OEM’s filters with the ADD-Vantage 9000 cleanable stainless screen element and dual magnetic filter.

Hydraulics

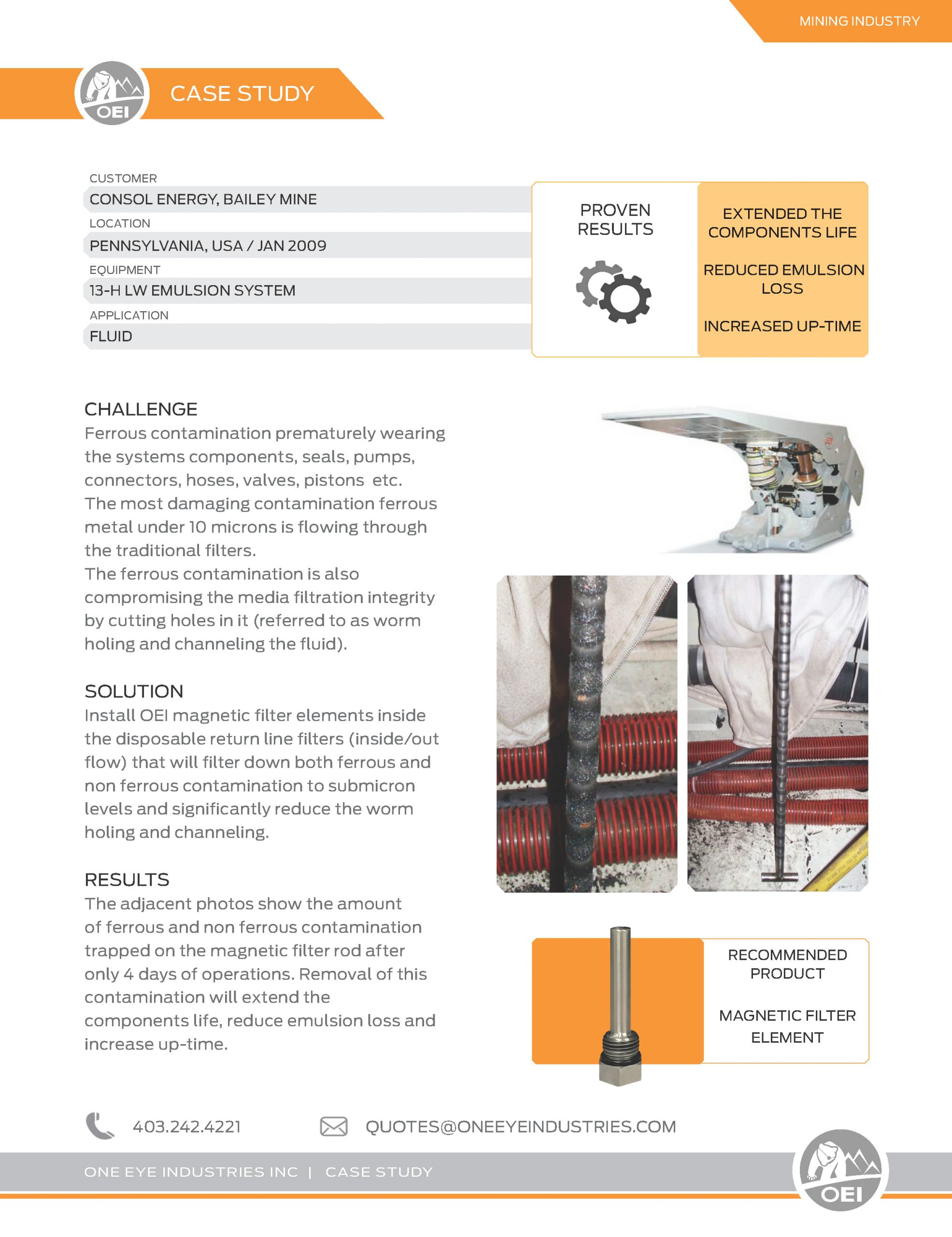

Consol Energy Longwall Emulsion System

Ferrous Contamination prematurely wearing the systems components, seals, pumps, connectors, hoses, valves, pistons etc. The most damaging contamination ferrous metal under 10 microns is flowing through the traditional filters. The ferrous metal is also compromising the media filtration integrity by cutting holes in it (referred to as worm holing and channeling the fluid).

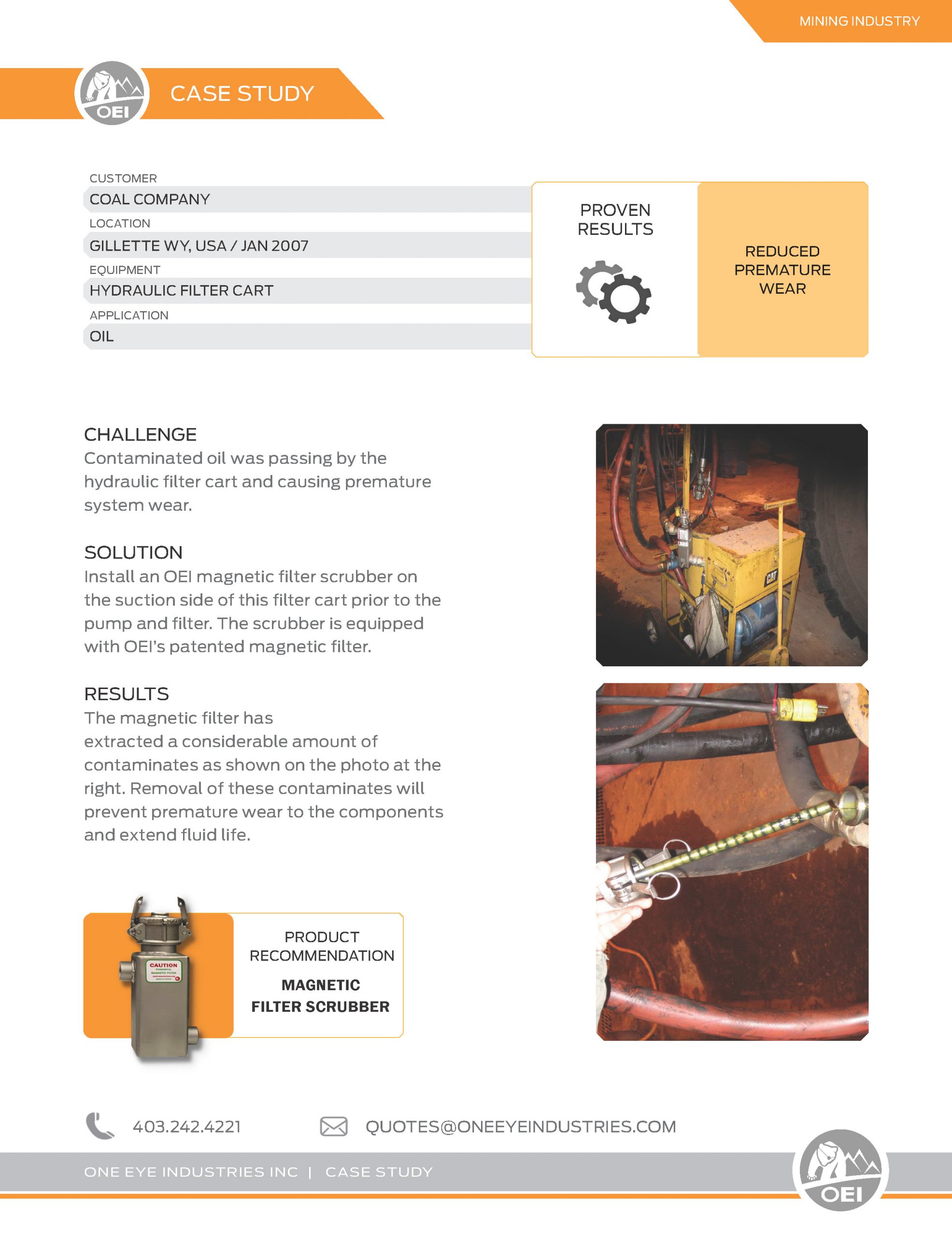

Coal Company Hydraulic Filter cart

OEI installed their 4000 Series Scrubber on the suction side of this filter cart prior to the pump and filter (Photo A). The Scrubber is equipped with OEI’s patented magnetic filter.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product is right for you

REQUEST A QUOTE

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com