Oil, Gas & Chemical Plant

OEI offers innovative and performance driven magnetic filters that enable increased efficiency and reduced plant operating costs. With applications on all facility rotating equipment, OEI protects chemicals,hydraulic fluid, process water, pumped fluids, compressed gases, lube oils, amine, coolantand compressed gases from the most damaging wear contamination. For information on black powder contamination removal from hydrocarbon, petrochemical and water process applications, visit OEI’s sister company, Black Powder Solutions, at blackpowdersolutions.com.

Featured Case Study

Proven Result: Improved Dehydration Efficiency

Customer

ENI Drilling Company

Location

Adriatic Sea, Italy / 2015

Equipment

Offshore Gas Platform

Application

Glycol Dehydration

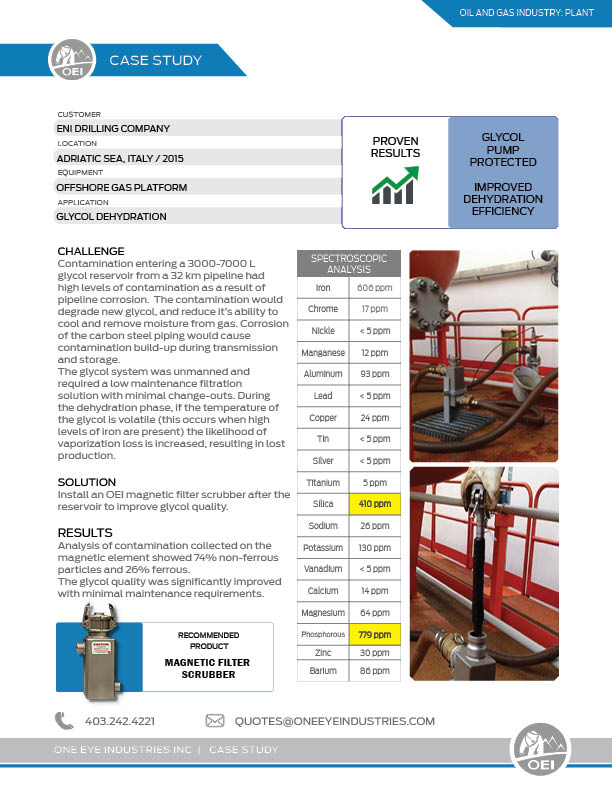

Problem

Contamination entering a 3000-7000 L glycol reservoir from a 32 km pipeline had high levels of contamination as a result of pipeline corrosion. The contamination would degrade new glycol, and reduce it’s ability to cool and remove moisture from gas. Corrosion of the carbon steel piping would cause contamination build-up during transmission and storage.

The glycol system was unmanned and required a low maintenance filtration solution with minimal change-outs. During the dehydration phase, if the temperature of the glycol is volatile (this occurs when high levels of iron are present) the likelihood of vaporization loss is increased, resulting in lost production.

Solution

Install an OEI magnetic filter scrubber after the reservoir to improve glycol quality.

Results

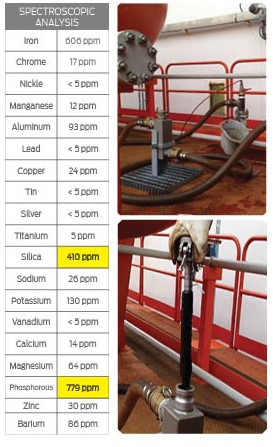

Analysis of contamination collected on the magnetic element showed 74% non-ferrous particles and 26% ferrous.

The glycol quality was significantly improved with minimal maintenance requirements.

Oil, Gas and Chemical Plant

CASE STUDIES

Chemical Plants

Protecting Momentives Chemical Plant Mag Drive Pumps

The challenge was to reduce high levels of contamination causing premature failure of the pumps and seals. The contamination was a result of erosion and corrosion of the piping caused by the dangerous process fluid Trimethoxy(methyl)silane (CAS number 1185-55-3).

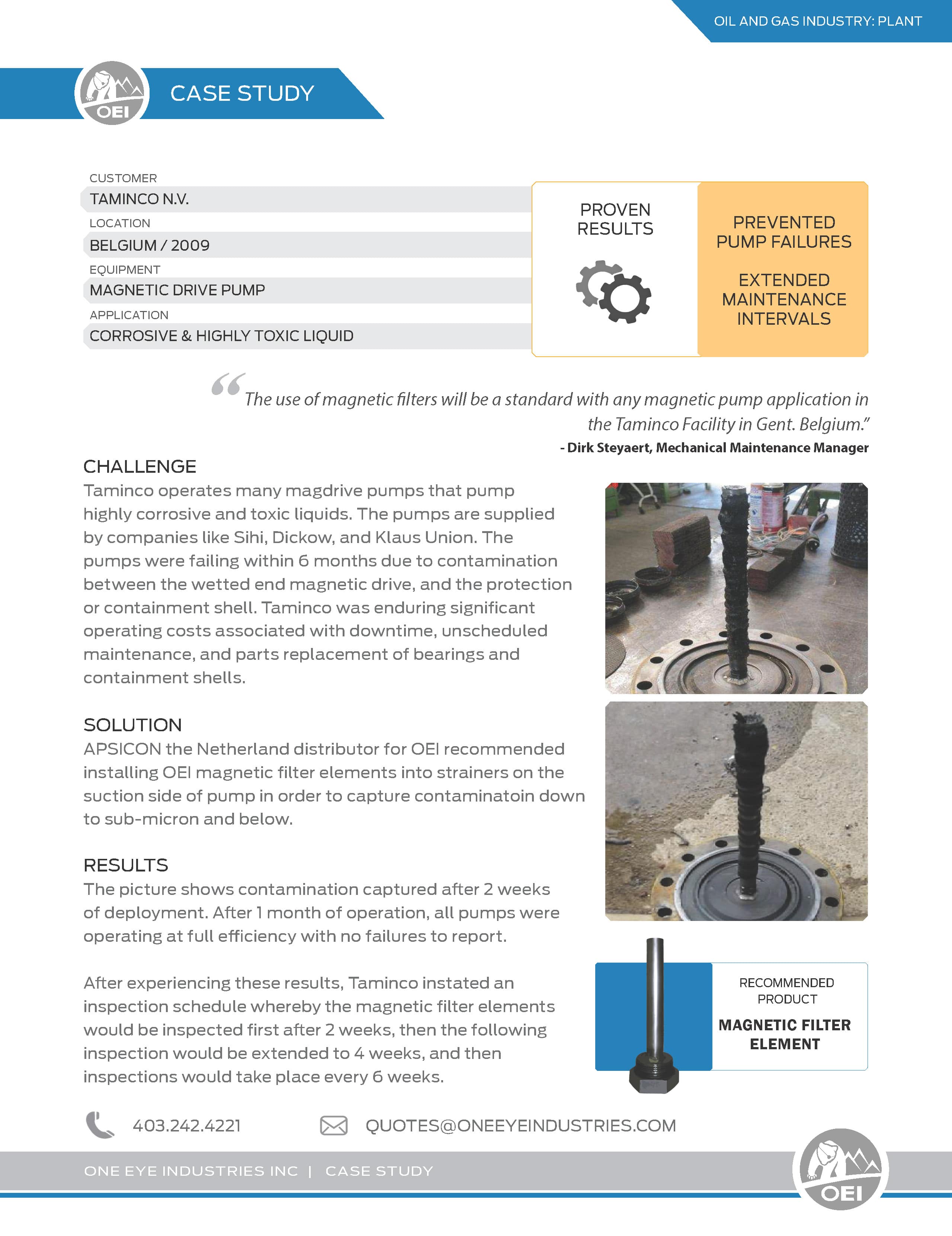

Protecting Taminco’s Magnetic Drive Pumps

Taminco operates many magdrive pumps that pump highly corrosive and toxic liquids. The pumps are supplied by companies like Sihi, Dickow, and Klaus Union. The pumps were failing within 6 months due to contamination between the wetted end magnetic drive, and the protection or containment shell. Taminco was enduring significant operating costs associated with downtime, unscheduled maintenance, and parts replacement of bearings and containment shells.

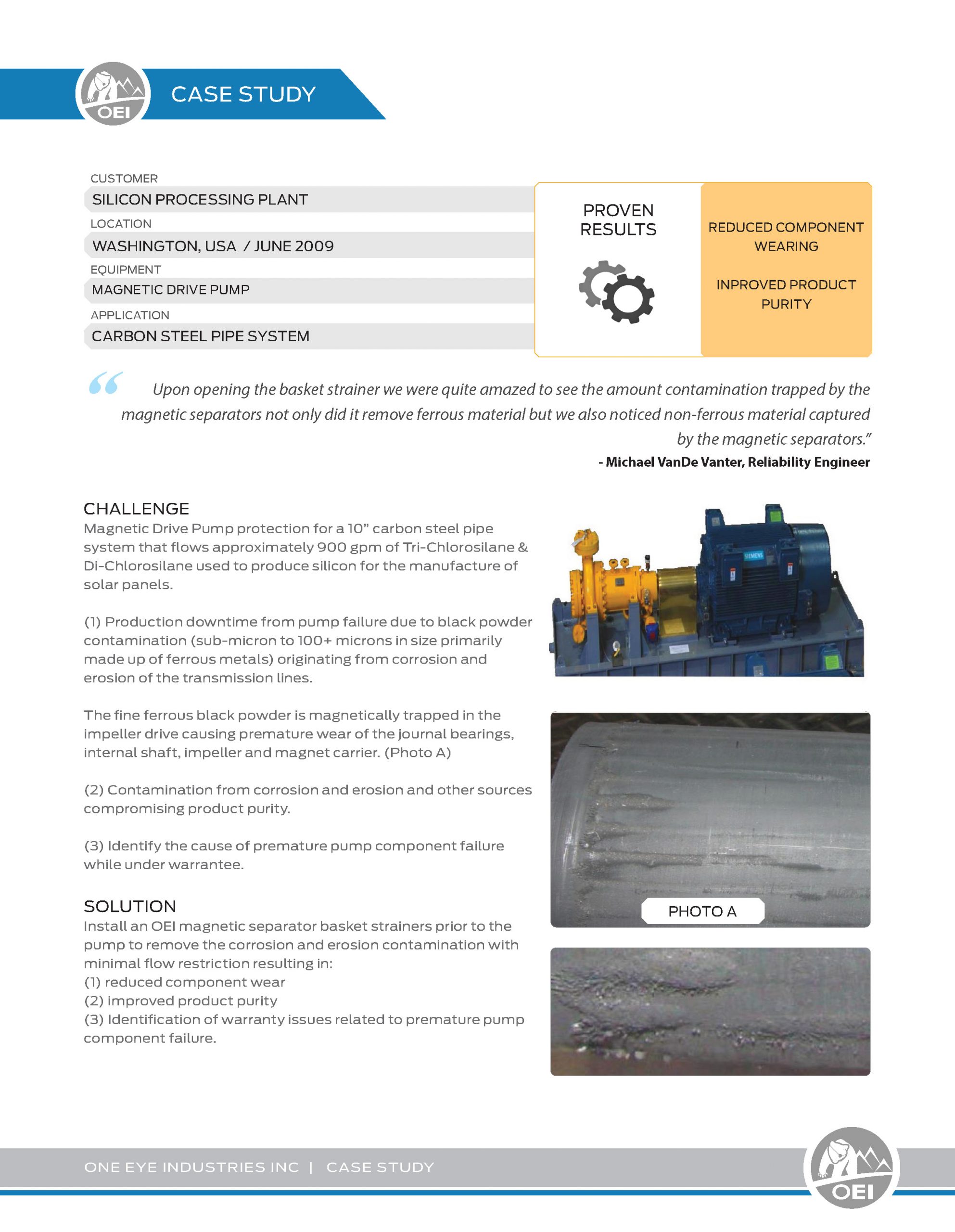

Chemical Plant Mag Drive Filtration

Magnetic Drive Pump protection for a 10” carbon steel pipe system that flows approximately 900 gpm of Tri-Chlorosilane & Di-Chlorosilane used to produce silicon for the manufacture of solar panels.

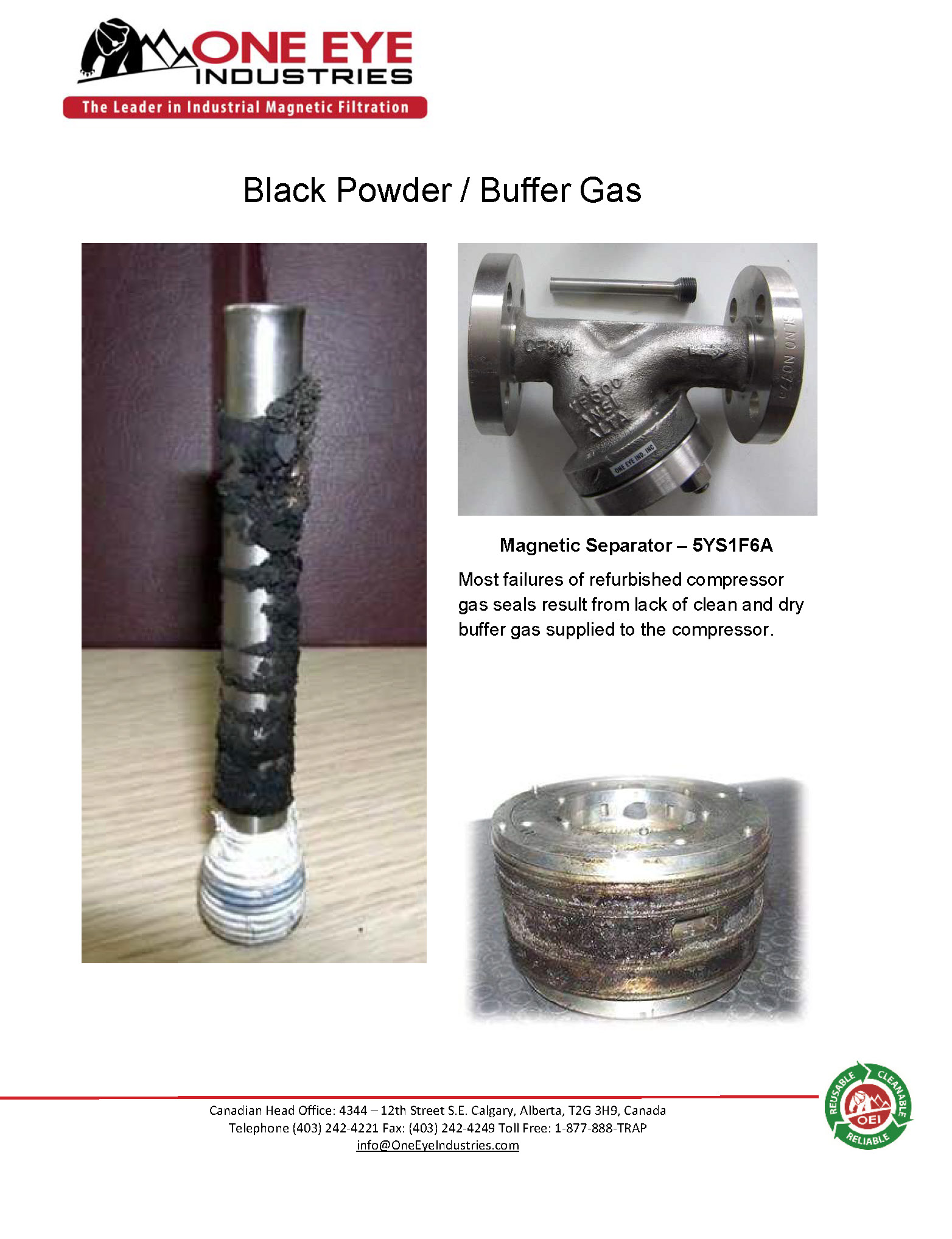

Power Engineering Compressor Buffer Gas

Most failures of refurbished compressor gas seals result from lack of clean and dry buffer gas supplied to the compressor, according to a recent analysis conducted by a leading supplier of engineered sealing systems and associated products. These seals are used on most pipeline compressors that supply gas to gas turbines at power plants and in compression systems needed to boost gas pressure in power plant gas turbines.

Compressors

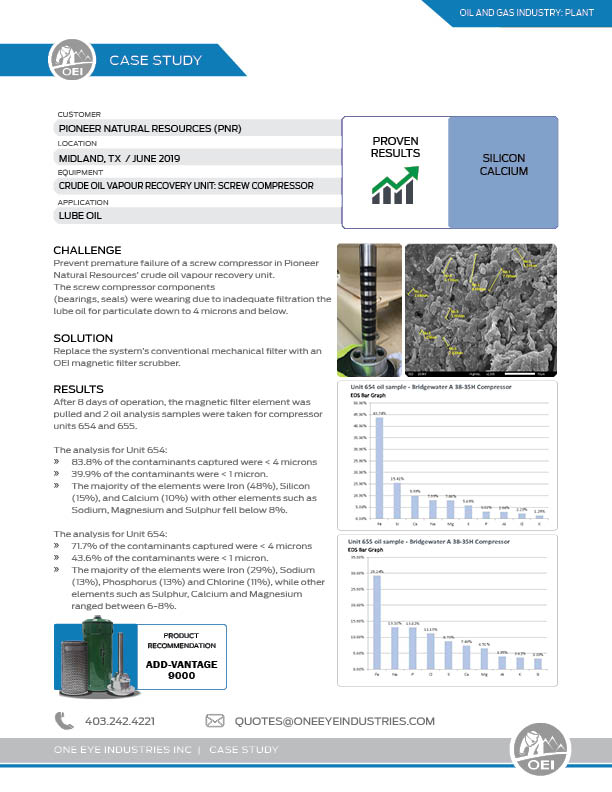

Screw Compressor Lube Oil Analysis

The challenge was to prevent premature failure of a screw compressor in Pioneer Natural Resources’ crude oil vapour recovery unit. The screw compressor components (bearings, seals) were wearing due to inadequate filtration the lube oil for particulate down to 4 microns and below.

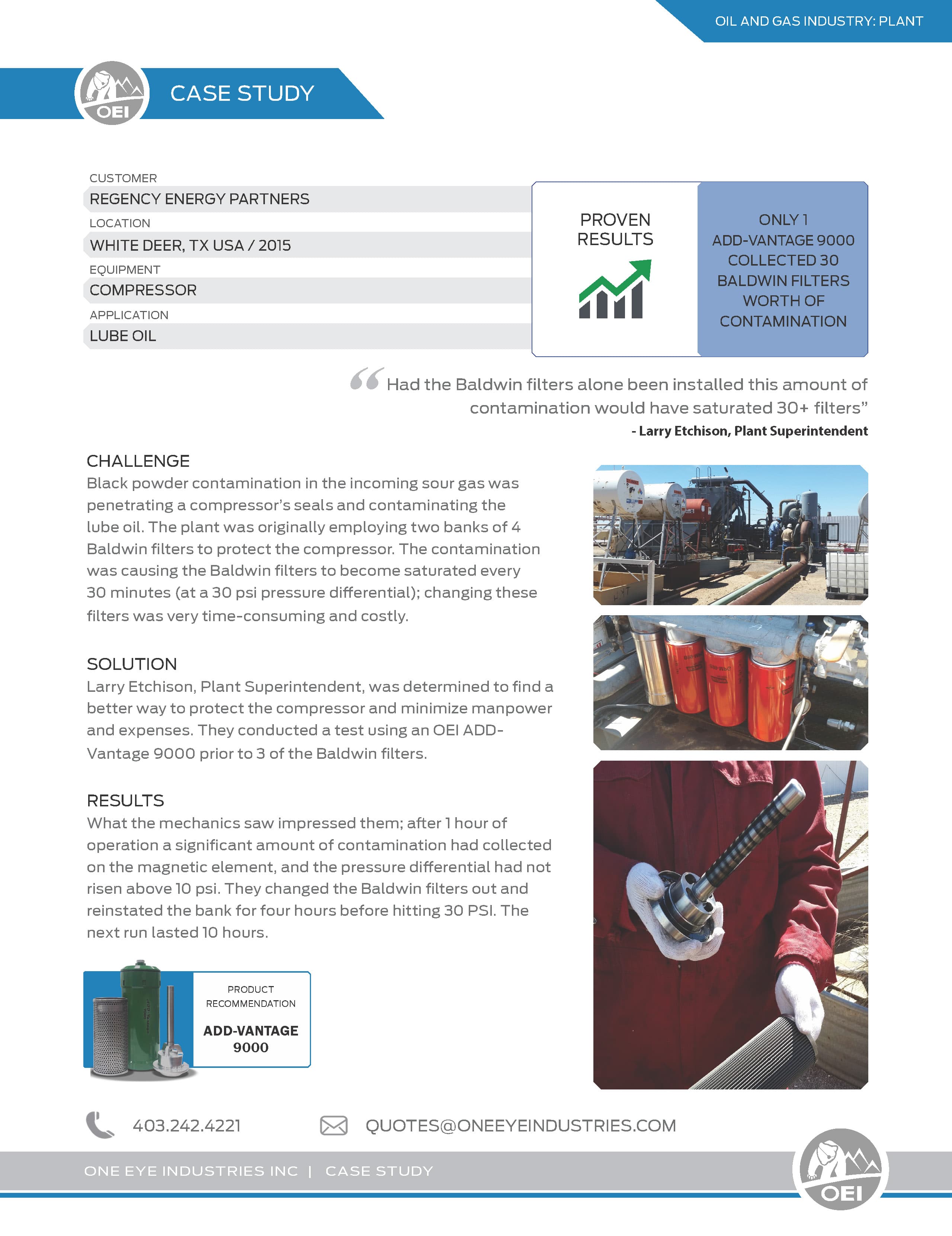

Regency Energy Partners Compressor Lube Oil

Black powder contamination in the incoming sour gas was penetrating a compressor’s seals and contaminating the lube oil. The plant was originally employing two banks of 4 Baldwin filters to protect the compressor. The contamination was causing the Baldwin filters to become saturated every 30 minutes (at a 30 psi pressure differential). Changing these filters was very time-consuming and costly.

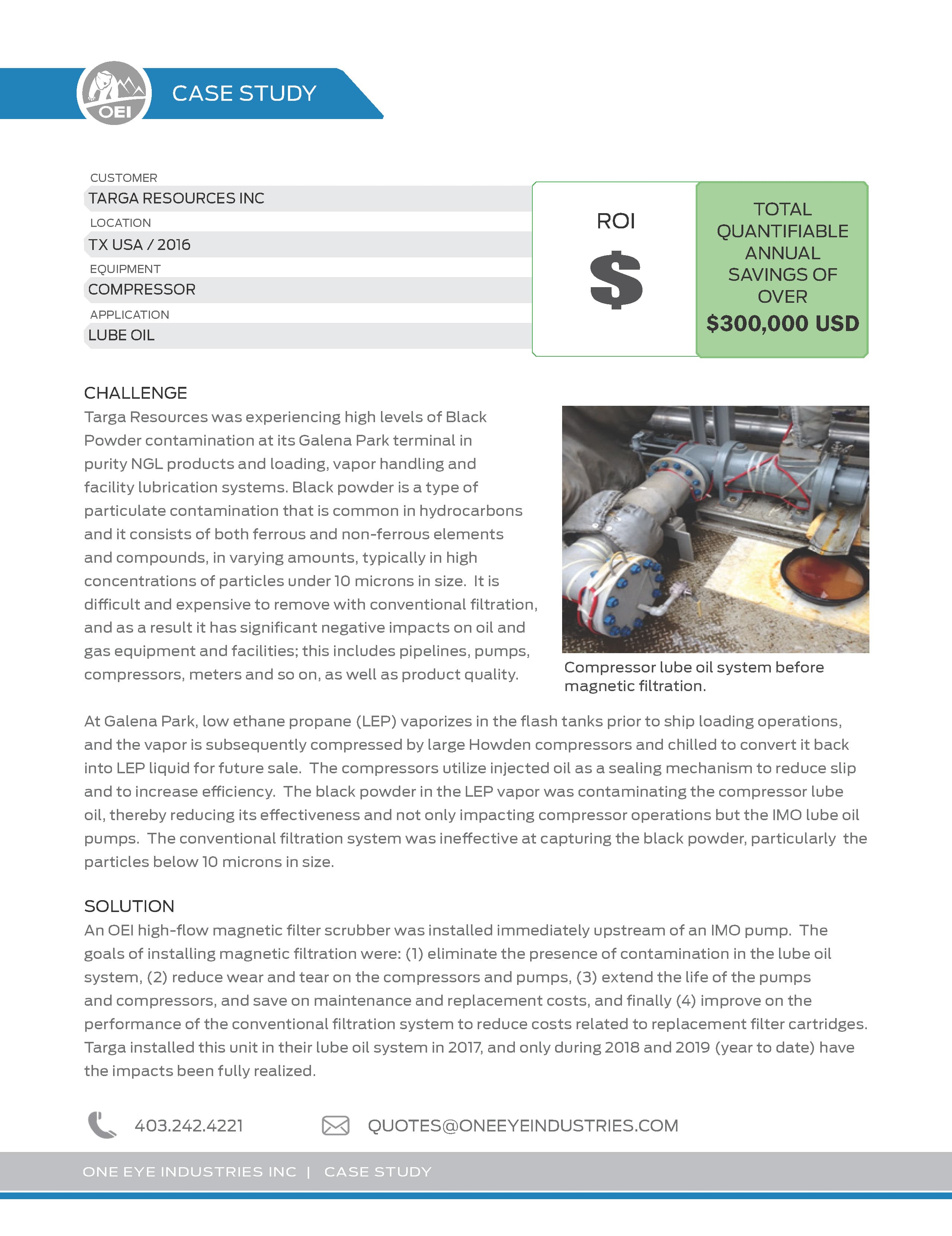

Targa Resources Compressor Lube Oil Filtration Saves 300k Annually

The challenge was to remove black powder contamination at Targa’s Galena Park temrinal in purity NGL products and loading, vapor handling and facility lubrication systems.

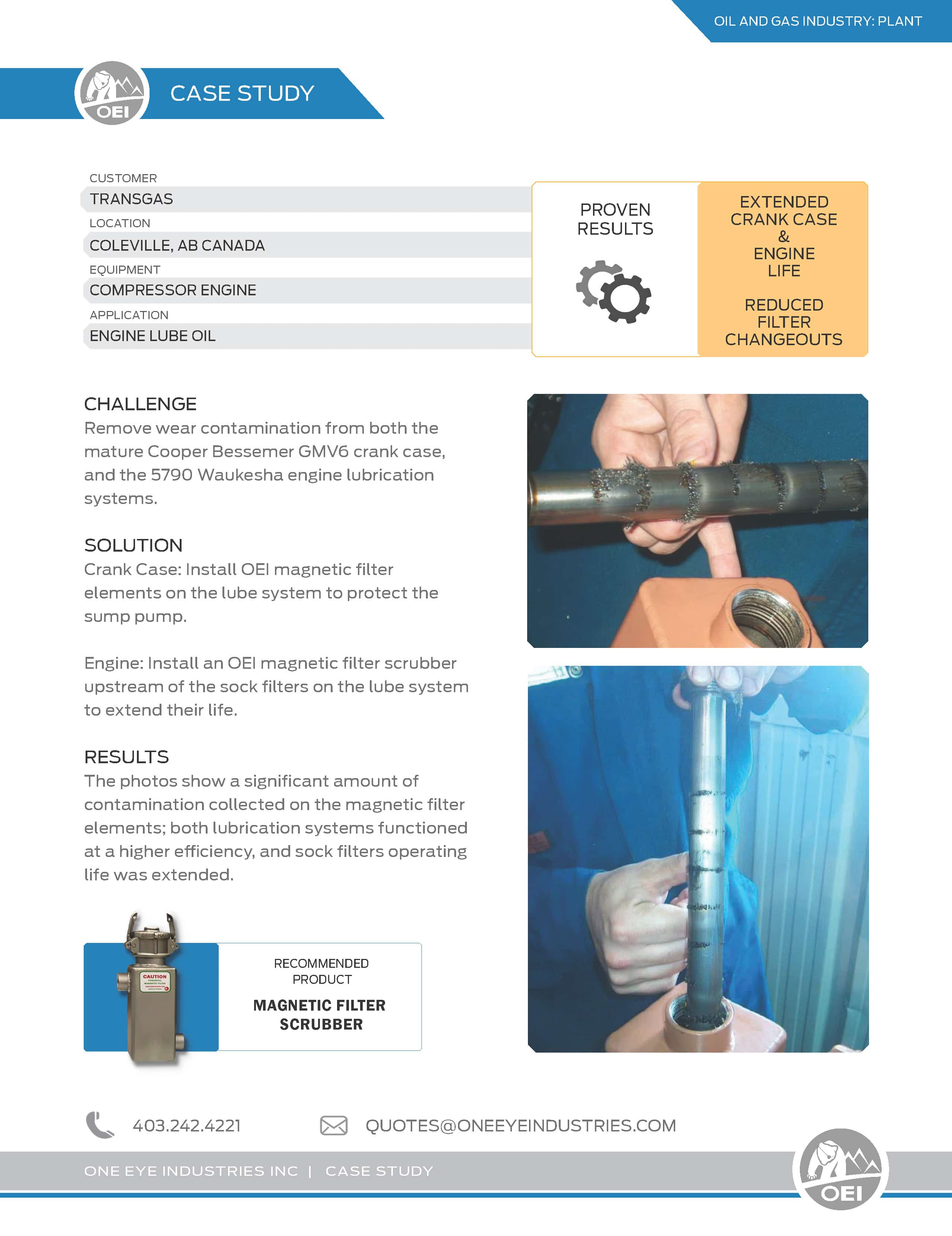

Transgas Crank Case & Engine Lube Oil

The challenge was to remove wear contamination from both the mature Cooper Bessemer GMV6 crank case, and the 5790 Waukesha engine lubrication systems.

Natural Gas Processing Facility Compressor Lube Oil

An intermediate oil and gas producer in Western Canada was experiencing high levels of Black Powder contamination at their natural gas processing facility. The facility employs a 1500-HP natural-gas-flooded screw compressor; the system is open loop which means the lube oil mixes with the rich natural gas, and is separated out as it passes through the machine. These types of systems are highly susceptible to premature wear because the components are exposed to all types of formation contamination (Black Powder) and solvents during operation. The OEM 3-micron filters have a low holding capacity and would only last 3 weeks on average. Once in bypass, the compressor would shut down due to high pressure differential. In some cases, the OEM paper filters would disintegrate completely, causing a total loss of machine lube oil and very costly cleanup.

ENI Compressor Lube Oil

Oil analysis identified a high level of wear contamination in the NP#2 compressor lube oil. If left in the system will cause premature wear of the compressor components. Traditional filtration was unable to remove this contamination under 10 microns and the most damaging contamination is iron and steel under 10 microns. The inefficient disposable elements caused increased change outs and maintenance intervals.

NAL Resources Compressor Lube Oil

Installed an OEI magnetic filter rod on his portable oil change cart and then installed OEI magnetic filters at each compressor engine lube line via a T-pipe access.

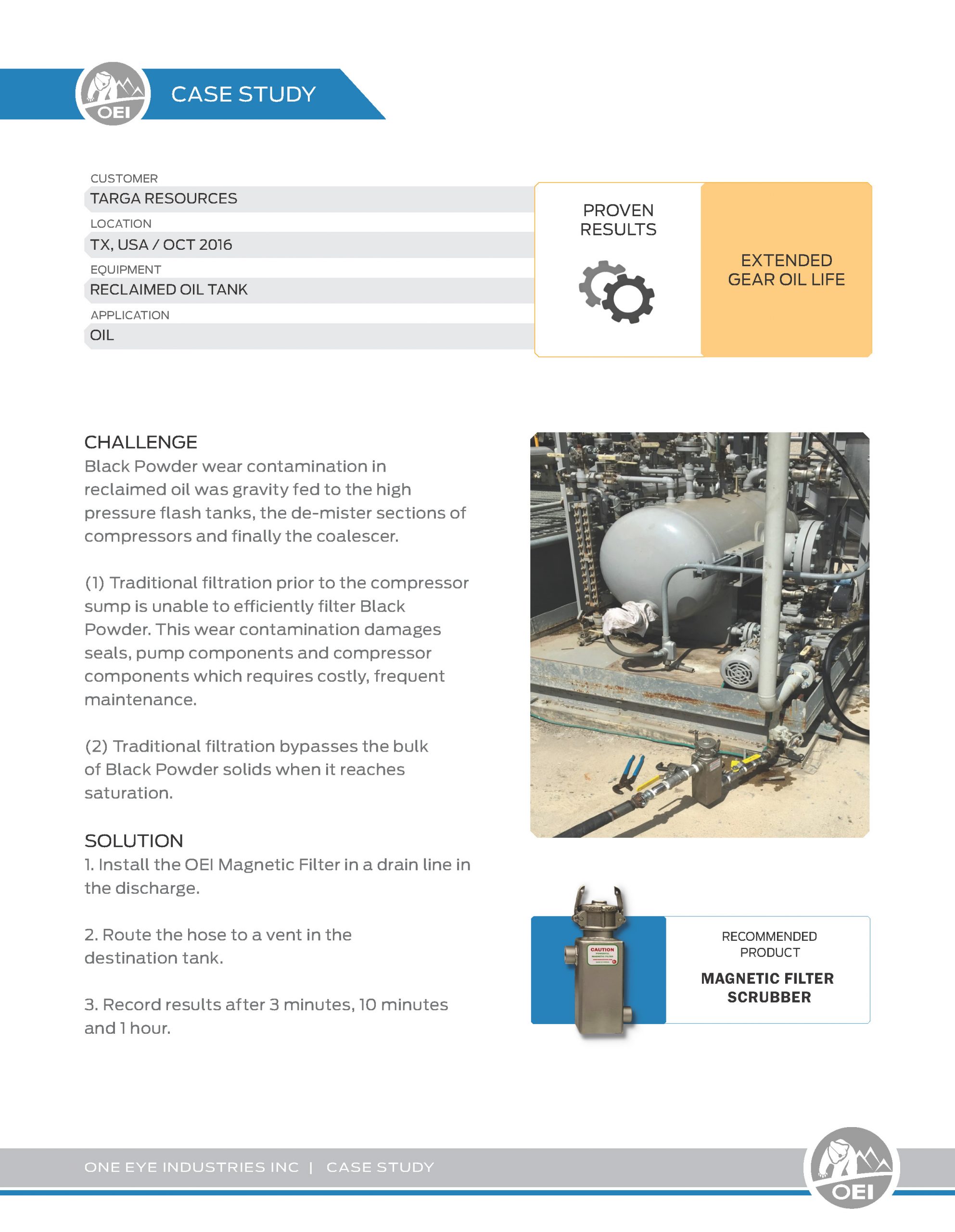

Targa Reclaimed Oil Separator

Black Powder wear contamination in reclaimed oil was gravity fed to the high pressure flash tanks, the de-mister sections of compressors and finally the coalescer.

Cooling Systems

Burlington Resources Glycol Pump Protection

The challenge was to reduce ferrous particles in the system, as they led to pump failure, and conventional filters were not effectively removing the contamination. Maintenance Manager for Burlington Resources wanted to prevent pump failures and reduce contamination down to 4 microns and below.

ENI Glycol Gas De-hydration Improvement

Contamination entering a 3000-7000 L glycol reservoir from a 32 km pipeline had high levels of contamination as a result of pipeline corrosion. The contamination would degrade new glycol, and reduce it’s ability to cool and remove moisture from gas. Corrosion of the carbon steel piping would cause contamination build-up during transmission and storage. The glycol system was unmanned and required a low maintenance filtration solution with minimal change-outs. During the dehydration phase, if the temperature of the glycol is volatile (this occurs when high levels of iron are present) the likelihood of vaporization loss is increased, resulting in lost production.

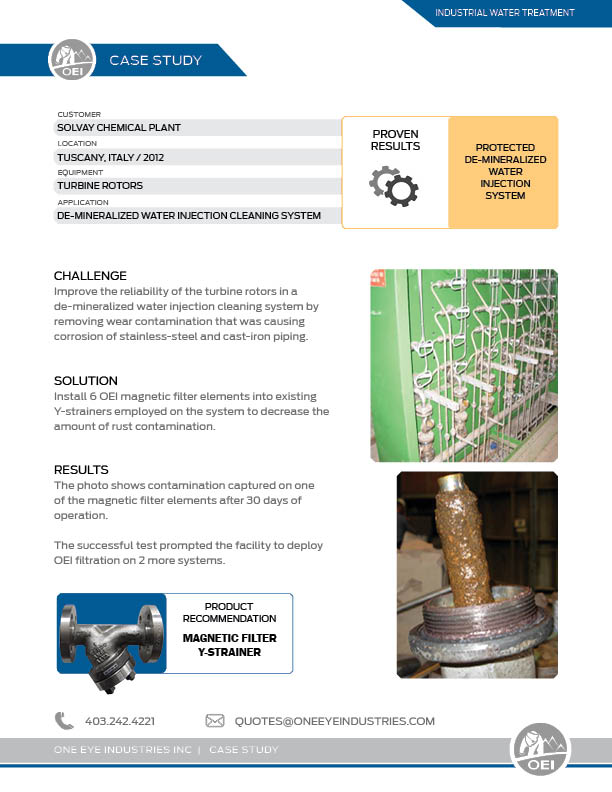

Solvay Chemical De-mineralized Water Injection System

Improve the reliability of the turbine rotors in a de-mineralized water injection cleaning system by removing wear contamination that was causing corrosion of stainless-steel and cast-iron piping.

Gearboxes

Ineos Flender Gearbox Lube Oil

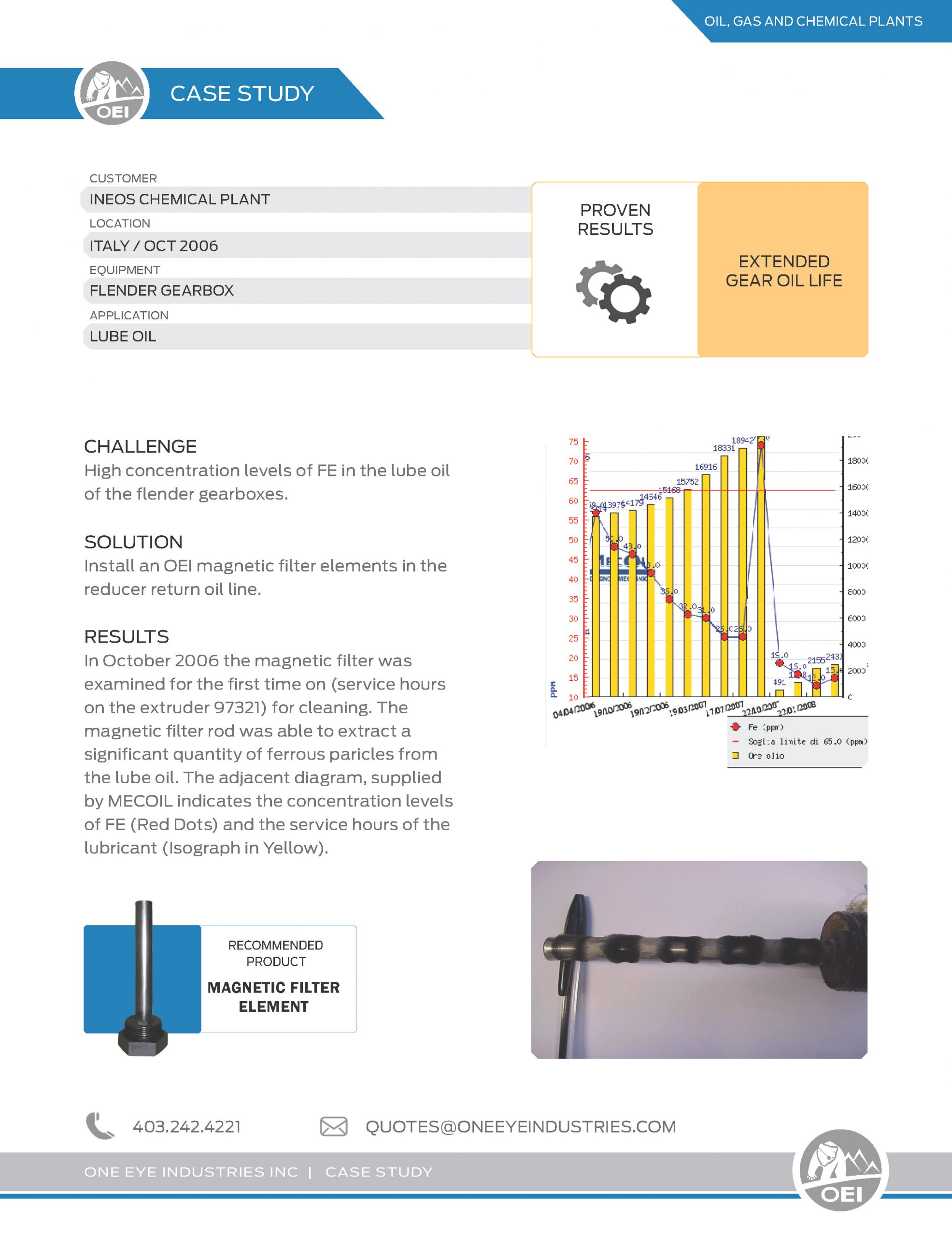

19/10/2006 the magnetic filter was examined for the first time on (service hours on the extruder 97321) for cleaning. The magnetic filter rod was able to extract a significant quantity of ferrous metal from the lube oil.

Heat Exchangers

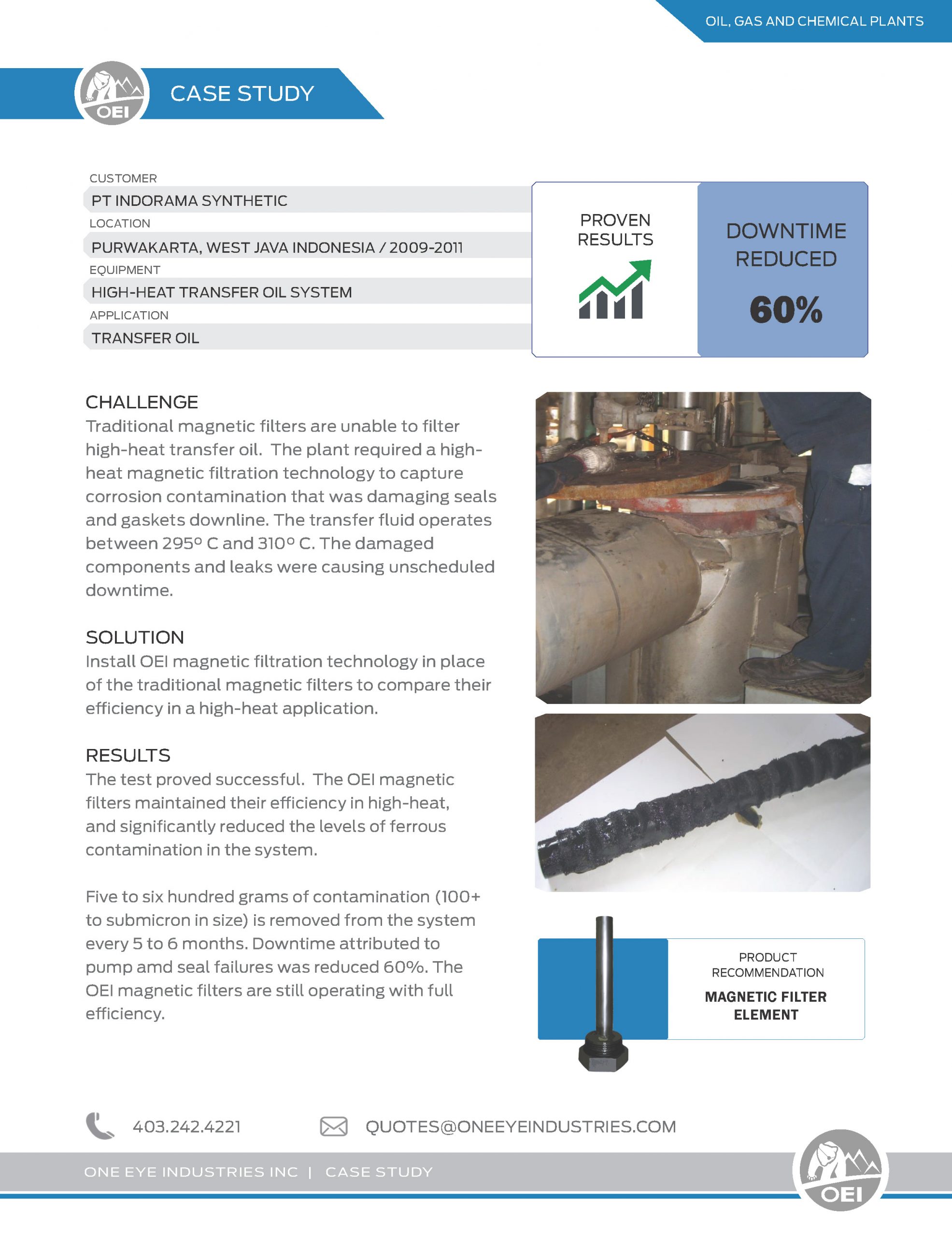

PT Indorama Chemical Plant High-heat Transfer Fluid

Traditional magnetic filters are unable to filter high-heat transfer oil. The plant required a highheat magnetic filtration technology to capture corrosion contamination that was damaging seals and gaskets downline. The transfer fluid operates between 295° C and 310° C. The damaged components and leaks were causing unscheduled downtime.

Alliance Pipelines’ Heat Recovery System Protection

The challenge was to reduce high levels of contamination in the pentane waste and heat recovery systems of Alliance Pipelines’ heat recovery system. The contamination was prematurely wearing pumps, seals, and piping components. This system operated at 350 gallons per minute with a viscosity of 0.24CP at 20 degrees F.

OEI magnetic filters are designed for 95+% efficiency: they are optimized for fluid viscosity, flow volume, flow rate, temperature, mobility, and mounting requirements.

Use of the OEI Data Form will provide the necessary specifications for OEI to determine which product is right for you

REQUEST A QUOTE

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com