SOLVING TOMORROW’S CHALLENGES, TODAY.

Sustainable magnetic filtration solutions for machinery operators around the world.

OEI magnetic filtration is the simplest way to achieve rapid payback with the lowest risk by extending the life of rotating equipment. As a result, safety is improved while substantially reducing the costs and the environmental impact of operations.

Answer your questions about reliability

Our learning center is where reliability managers and technicians go to learn more about fluid management, overcoming equipment challenges, and implementing best maintenance practices.

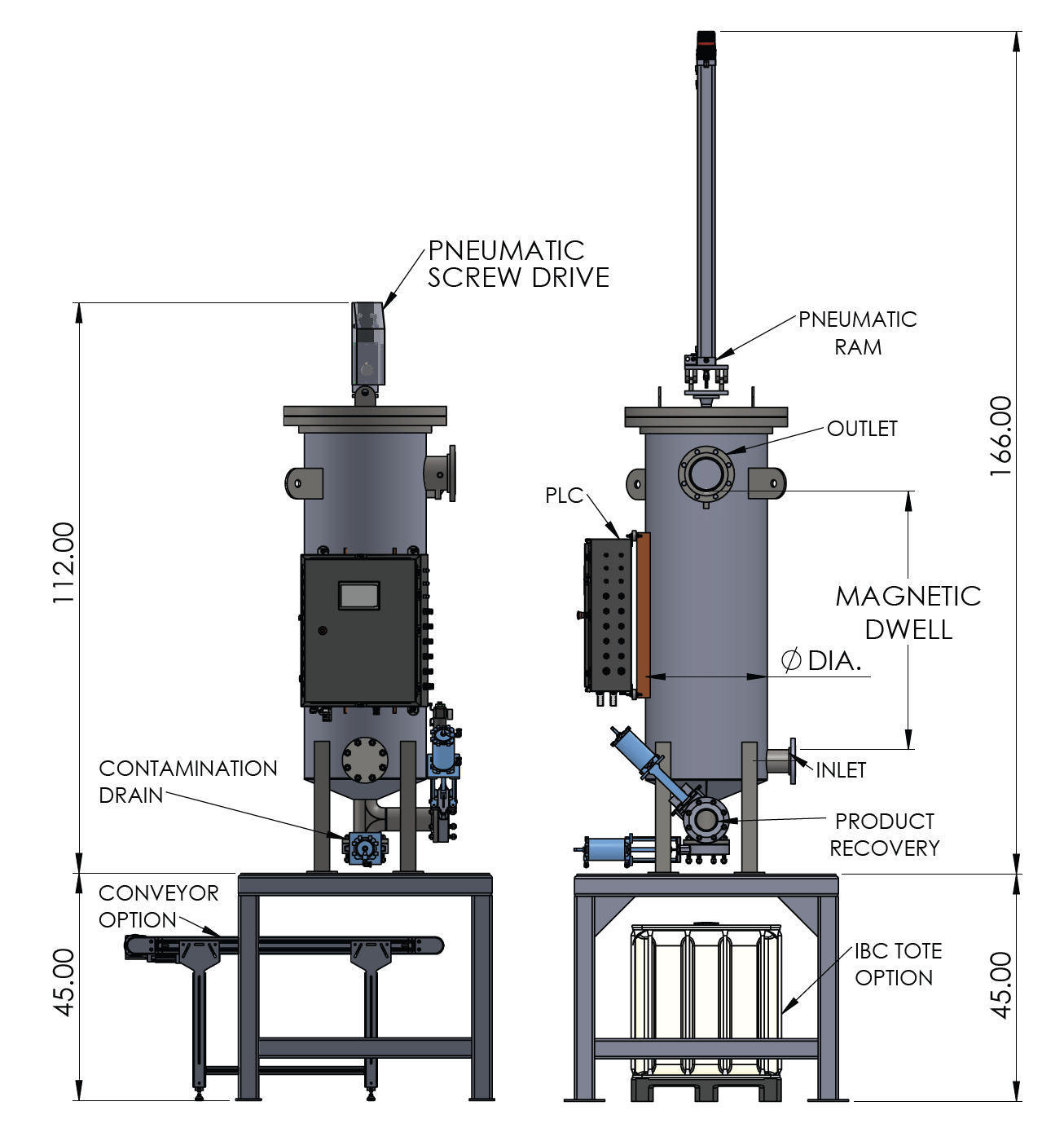

Introducing Our New Design

Automated Magnetic Filtration

OEI is pleased to announce our new design Automated Magnetic Filtration (AMF) for cleaning cooling cutting oil of the metal contamination down to and below 1 micron particles for the milling industry.

The Fully Automated Magnetic Filtration System is installed with a drop chute into a holding container or onto a conveyor for disposal. During the automatic cleaning cycle, the oil or water will be recovered before activating the cleaning cycle to ensure minimal loss. Our system cleans the iron, dramatically reducing the opportunity for bacteria to grow, and significantly reducing the odour and extends the operating life of the cooling oil.

One Eye Industries Launches “CleanMud Filtration Systems(TM)” and Uncovers an Unknown 1%

One Eye Industries Inc. (OEI) has launched CleanMud Filtration Systems™, the company’s latest innovation in magnetic filtration. CleanMud Filtration is designed to filter wear contamination from oil, water and chemical-based mud, along with fracking and completion...

One Eye Industries Launches “CleanMud Filtration Systems(TM)” and Uncovers an Unknown 1%

One Eye Industries Inc. (OEI) has launched CleanMud Filtration Systems™, the company’s latest innovation in magnetic filtration. CleanMud Filtration is designed to filter wear contamination from oil, water and chemical-based mud, along with fracking and completion fluid. The patented technology removes more than 95 per cent of wear contamination down to and below one micron in size.

How Magnetic Filtration Improved The Reliability Of An Offshore Wind Turbine

Vattenfall is a market leader in both onshore and offshore wind, with over 50 wind farms in operation across Europe. In efforts to advance wind energy’s cost competitiveness and reliability, Vattenfall required a solution for reducing premature bearing failures in their turbine gearboxes.

Protect Your Equipment

Download The Ultimate Guide To Fluid Management And Equipment Reliability

4344 12th Street SE Calgary,

AB T2G 3H9 Canada

(403) 242 4221

quotes@oneeyeindustries.com

One Eye Industries Inc. does not directly offer or supply engineering services. Our final designs and products are approved through qualified and legally authorized companies and individuals, including third parties, when appropriate.